Rice seedling transplanting mechanism with eccentric circle and non-circular gear planetary gear train

A technology of eccentric circular gears and non-circular gears, which is applied in the direction of transplanting machinery, belts/chains/gears, mechanical equipment, etc., can solve problems such as low efficiency, high price, and unsuitability, and achieve vibration reduction, small vibration, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

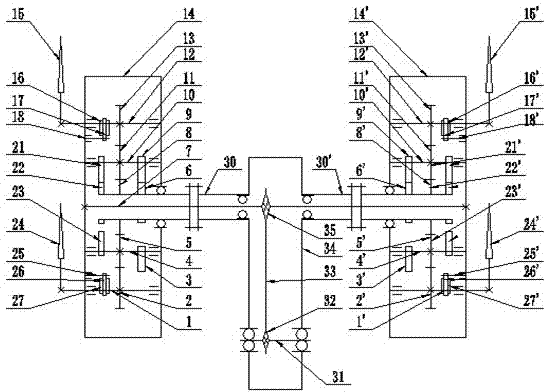

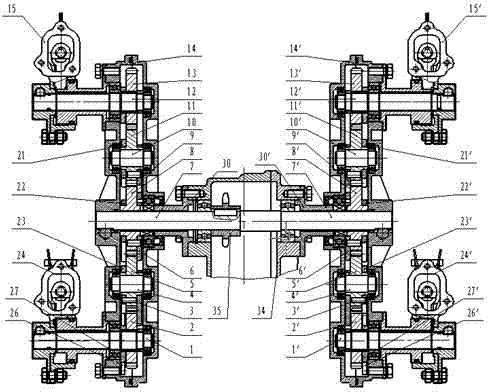

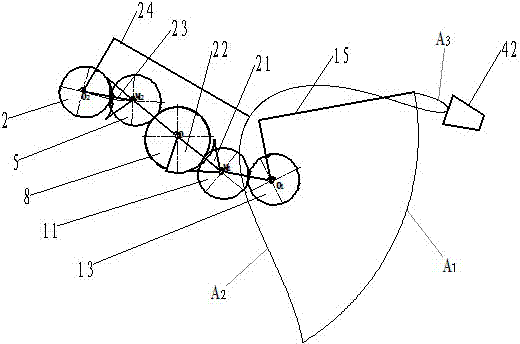

[0025] Such as figure 1 , figure 2 Shown, the present invention it comprises transmission part and transplanting arm; Driving sprocket 32 is housed on the power transmission shaft 31 in the sprocket case 34 of transmission part, through chain 33 and the center that is contained on the central axis 7 in sprocket case 34. The sprocket 35 is connected, and the left and right shaft ends on the left and right sides outside the sprocket box 34 of the central shaft 7 are fixed with the left and right gear boxes 14, 14 ′ with the same structure, and the left and right gear boxes 14, 14 ′ are respectively connected with The two ends of the central shaft 7 are fixedly connected to rotate together, and the upper left and lower planetary shafts 12, 1 and the upper right and lower planetary shafts 12', 1' extending out of the left and right gear boxes 14, 14' ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com