Manufacturing method of human engineering mattress

A technology of ergonomics and production methods, applied in the field of mattress production, can solve problems such as small resistance, failure to achieve healthy sleep, and no consideration of mattress rebound rate, etc., to achieve the effect of expanding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

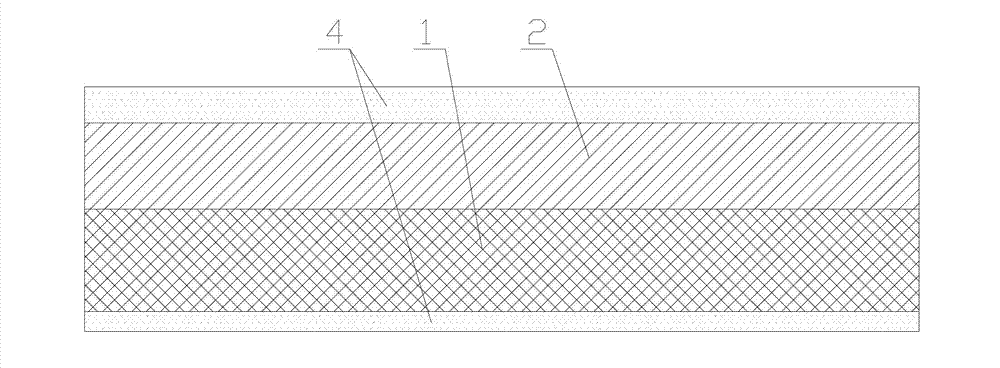

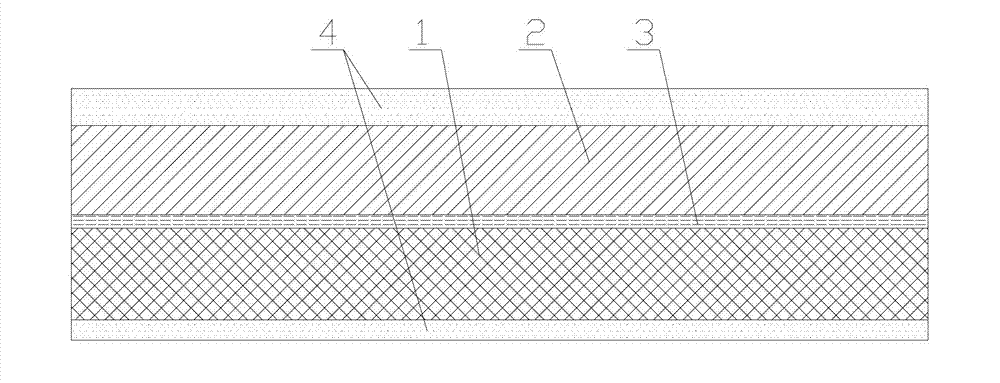

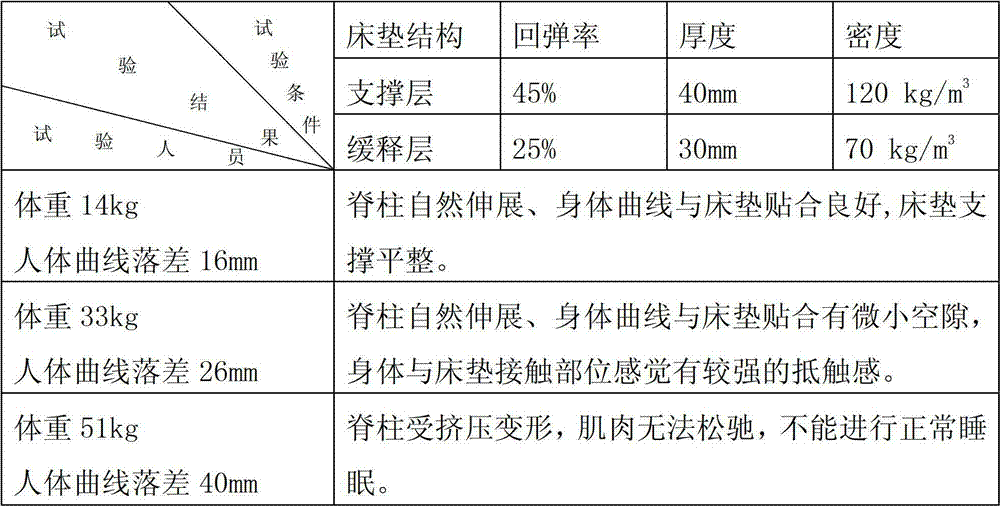

[0052] Embodiment 1 of the present invention. Ergonomic mattress manufacturing method, the mattress includes a support layer 1 and a slow-release layer 2, the rebound rate, thickness and density of the support layer 1 are selected according to the weight of the user during production, and the user is carried by the support layer 1 According to the drop of the user's body curve, the rebound rate, thickness and density of the slow-release layer 2 are selected, and the deformation of the slow-release layer 2 is used to wrap the user's body curve.

[0053] After testing, the selection range of the supporting layer 1 is as follows, which can achieve the effect of the present invention.

[0054] The user's weight T≤15kg, the rebound rate of the support layer 1 is 40-45%, the thickness is 30-50mm, and the density is 120-135kg / m 3 ;

[0055] 15kg3 ;

[0056] 40kg3 ;

[0057] 70kg3 ;

[0058] 100kg3 .

[0059] The selection range of sustained-release layer 2 is as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com