Filter media loss-free continuous drift sand filter

A quicksand filter without filter material technology, which is applied in the direction of loose filter material filter, gravity filter, filter separation, etc., can solve the problems of substandard filtered water quality and filter material loss, etc., and achieve good and stable water quality, reduce Effects of pollution and conservation of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

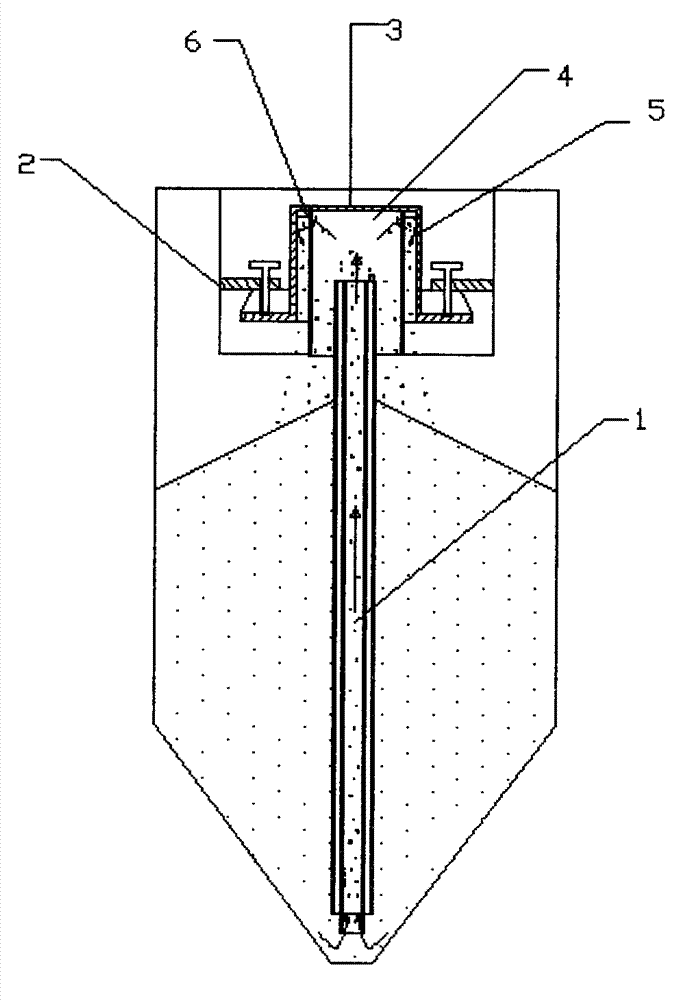

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Continuous flow sand filter with no loss of filter material, including an air lift pump 1 and a sand washer 2, characterized in that: the upper end of the air lift pump 1 is provided with a reflective sand control cover 3, and the reflective sand control cover 3 is fixedly connected to the sand washer 2 .

[0013] The upper end of the reflective sand control cover 3 is closed and the lower end is open, and is composed of a reflective sand control cover inner tube 4 and a reflective sand control cover jacket 5. The reflective sand control cover inner tube 4 is arranged inside the reflective sand control cover jacket 5, and the reflective sand control cover jacket The diameter of 5 is larger than the inner tube 4 of the reflective sand control cover, and the side wall of the inner tube 4 of the reflective sand control cover is provided with an exhaust hole 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com