Foot-chopping machine

A hoof splitting machine and splitting knife technology, applied in metal processing and other directions, can solve the problems of affecting product quality, high labor intensity, poor safety, etc., and achieve the effect of highlighting substantive characteristics, reducing labor intensity and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

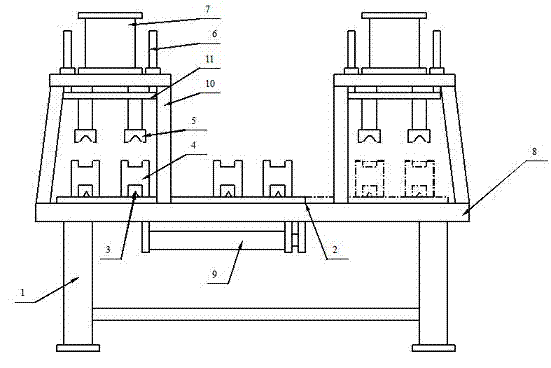

[0008] Example 1, see figure 1 , processed into a bracket 1, fix the guide rail 8 on the bracket 1, install the workbench 2 on the guide rail 8, connect the workbench 2 with the feed cylinder 9, and the workbench 2 is driven by the feed cylinder 9 on the guide rail 8 Move up; fixedly install the splitter 3 on the workbench 2, the blade end of the splitter 3 is upward, install the positioning sleeve 4 outside the splitter 3, the positioning sleeve 4 is fixed on the workbench 2, and the support frame is fixedly installed on the bracket 1 10. Install the hydraulic cylinder 7 on the support frame 10, fix the support plate 11 on the piston rod of the hydraulic cylinder 7, install the guide rod 6 on the support plate 11, and fix the punch 5 under the guide rod 6, the punch 5 and the There are four splitting knives 3 respectively, which constitute a set of splitting hoof devices, and the splitting hoof devices are two sets.

[0009] The hoof splitting machine described in the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com