Exhaust pipe cabin-through structure for top of ship chimney

A technology for exhaust pipes and chimneys, which is applied in the direction of ship propulsion, ship parts, propulsion parts, etc. It can solve the problems of chimney roof anti-corrosion paint damage and peeling, large temperature stress on chimney roof, chimney roof deformation, etc., to achieve simple structure, transmission The effect of less heat and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

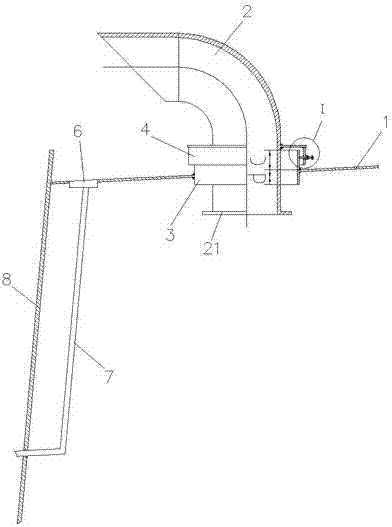

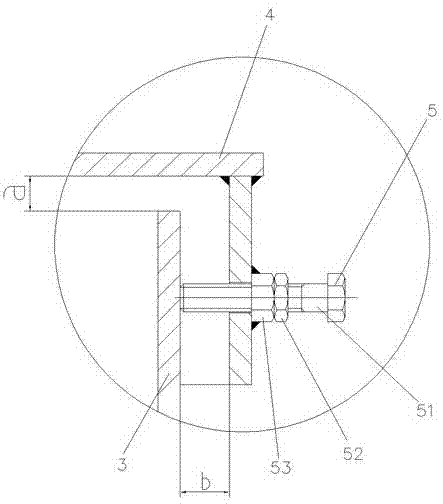

[0016] Such as figure 1 , figure 2 As shown, the present invention includes a slanted chimney roof 1, an exhaust pipe 2 arranged in the middle of the chimney roof 1, a fixed reinforcement coaming 3 fixed on the chimney roof 1, and a rain shield arranged on the upper side of the exhaust pipe 2. Plate 4 and four locking mechanisms 5 that support and position the exhaust pipe on the fixed reinforced coaming, the fixed reinforced coaming 3 is a cylindrical body, the lower side of which is welded in the opening in the middle of the chimney roof 1, and the inner diameter of the cylindrical shape is larger than that of the exhaust pipe. The flange 21 at the lower end of the gas pipe 2 has a diameter of 20 mm to 40 mm, which is convenient for the flange of the exhaust pipe 2 and its end face to be hoisted from top to bottom. The distance c between the top of the fixed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com