Apparatus and method for inhibiting TFT-LCD substrate glass bubbles

A glass and bubble technology, applied in glass furnace equipment, glass manufacturing equipment, glass transportation equipment, etc., can solve problems such as restrictions and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

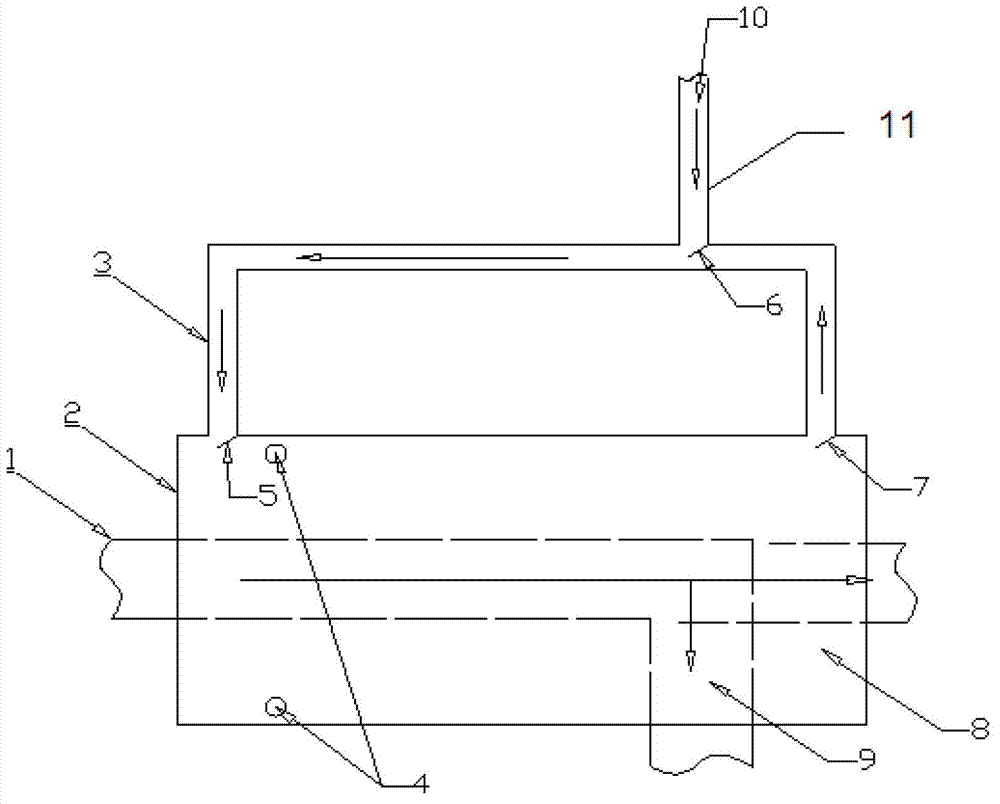

[0015] The illustrated case is the case of glass at high temperature (1200℃~1680℃). The material of the molten glass conveying pipe 1 is precious metals such as platinum, rhodium, palladium, or their alloys.

[0016] Such as figure 1 As shown, the high-temperature molten glass 9 flows through the molten glass conveying pipe 1, and a section of the pipe that flows through is surrounded by a sealed container 2. This section of the pipe can be straight or two small sections at a certain angle (more than 0°, Less than or equal to 90°) pipeline. The inner wall of the sealed container 2 is made of refractory insulation material, and the outer wall is made of non-magnetic stainless steel; the container contains the cooling section of the glass conveying channel; the minimum distance between the inner surface of the container and the outer surface of the glass conveying channel 1 is 100mm, and the maximum distance 3000mm, a sealed space 8 is formed between.

[0017] The steam 10 is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com