Automatic chemical nickel liquid medicine analyzing and adding system

A technology of automatic analysis and chemical liquid tank, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of inability to analyze, difficult to ensure the stability of chemical nickel plating liquid, and low control precision. Achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

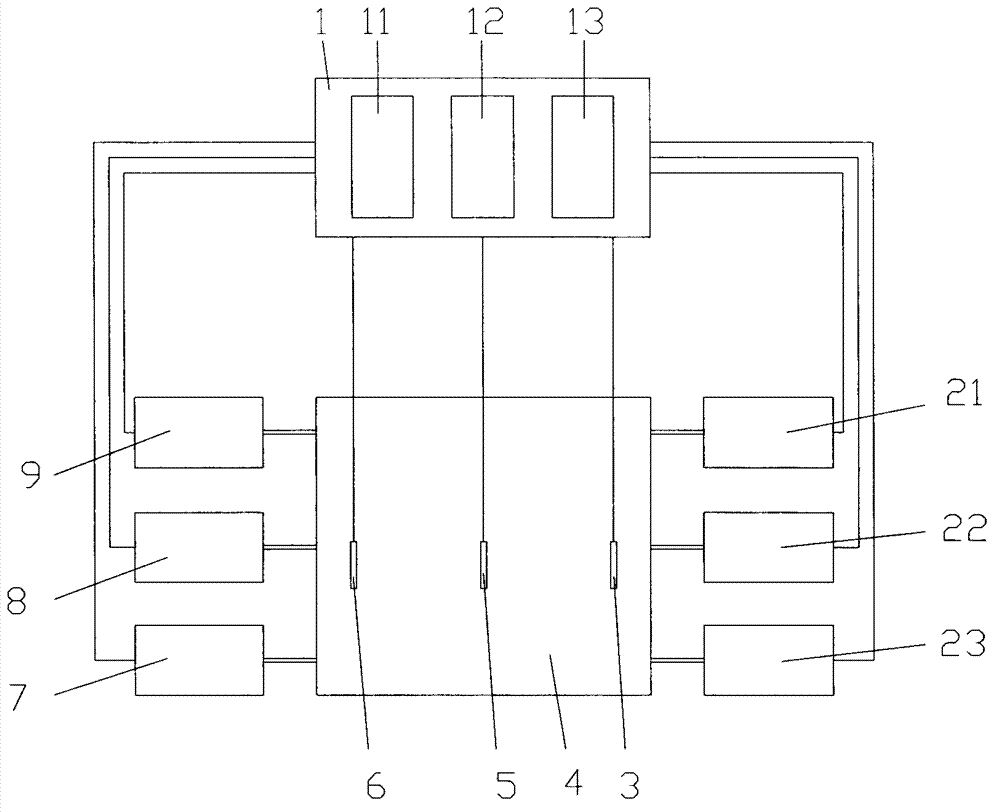

[0015] In order to describe in detail the technical characteristics of the present invention, the achieved purpose and effect, ideal parameter values during normal production: the nickel concentration is 5 ± 0.2g / L, the pH value is 5 ± 0.2g / L, and the temperature is 85 ± 2°C As an example, detailed description will be given in conjunction with the accompanying drawings.

[0016] When performing electroless nickel plating production, use the control input unit 12 in the controller 1 to input parameters: the nickel concentration is 5±0.2g / L, the pH value is 5±0.2g / L, and the temperature is 85±2°C. After parameter input, data analysis unit 13 can record this data, and data analysis unit 13 can gather the temperature value of current chemical nickel plating tank 4 by thermometer 6 simultaneously, gather the pH value of current chemical nickel plating tank 4 by pH meter 3, pass The atomic absorption spectrophotometer 5 collects and analyzes the current content of nickel ions in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com