Net rack plate type rotating support

A technology of rotating bearings and grid plates, which is applied to buildings and building structures, etc., can solve the problems of weak ability to bear horizontal loads, low horizontal stiffness, and inability to rotate, so as to enhance the ability to bear horizontal loads and improve its own performance. Small deformation, simple connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

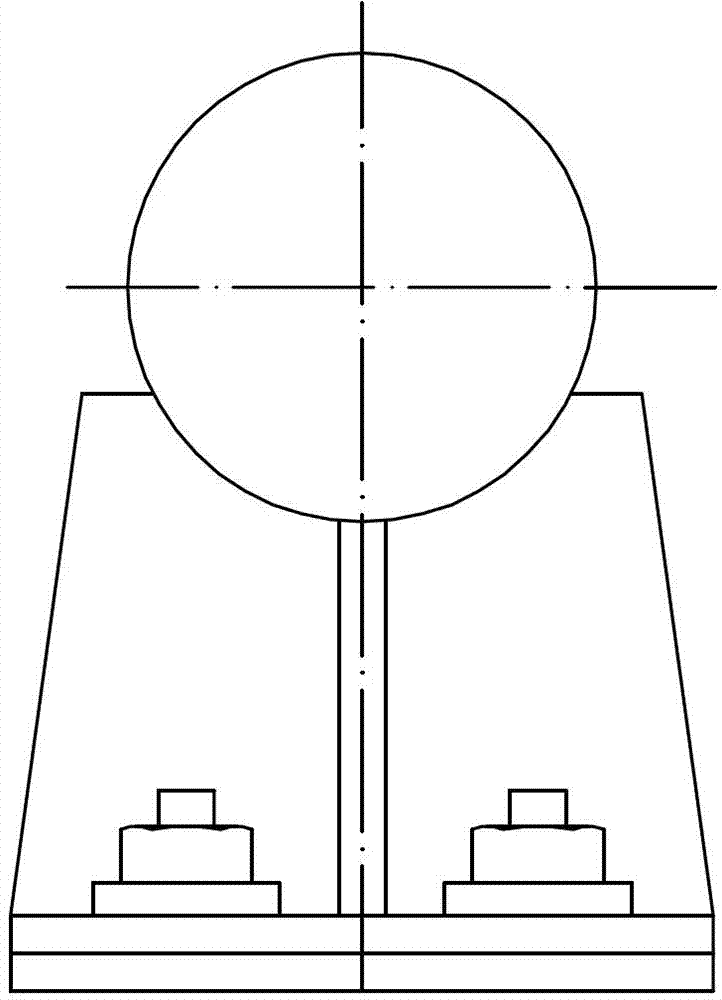

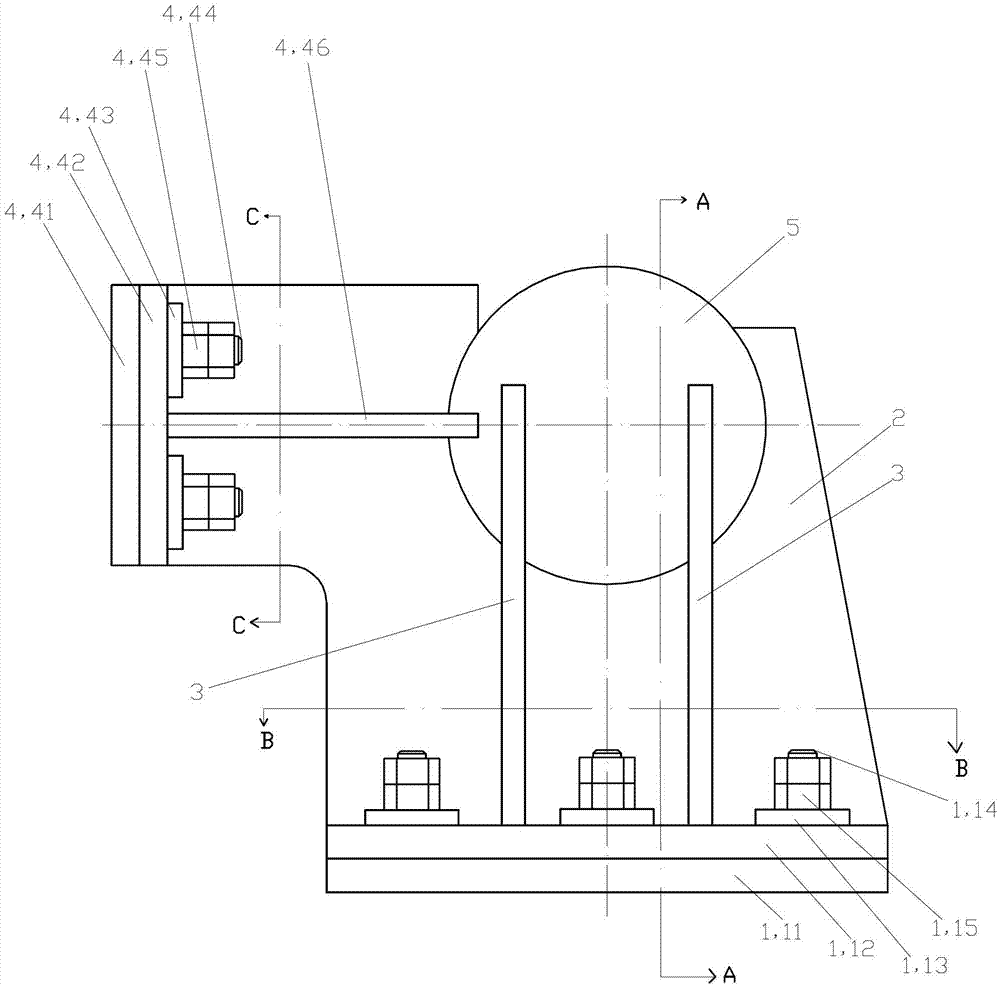

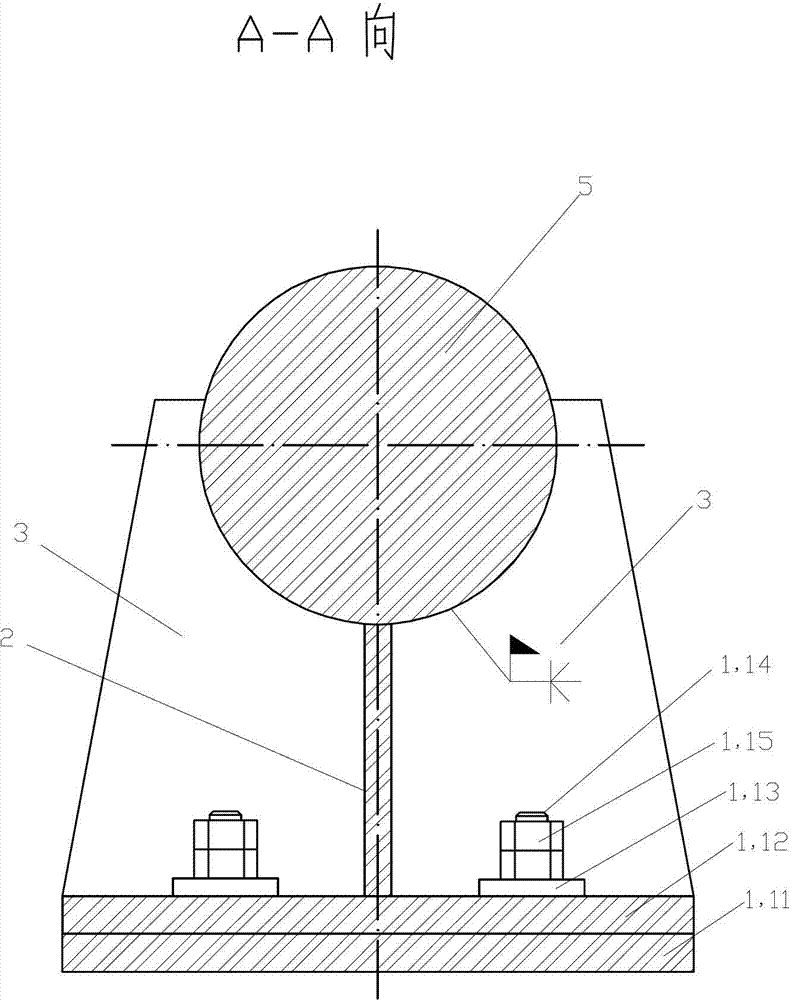

[0026] See figure 2 , The grid plate rotating bearing of this embodiment is composed of a base 1, a riser 2, a longitudinal stiffener 3, a lateral assembly 4 and a bearing ball 5.

[0027] See figure 2 with Figure 4 , The base 1 is composed of a transition plate 11 , a bottom plate 12 , a gasket 13 , plug welding bolts 14 and nuts 15 .

[0028] The material of the transition plate 11 is Q235B steel plate, the shape of the transition plate 11 is square, and it is arranged horizontally. The transition plate 11 is provided with 2 rows of front and back, each row of 3 plug welding holes, and the 3 plug welding holes of each row are evenly arranged on the same straight line in the left and right directions.

[0029] The base plate 12 is made of Q235B steel plate. The size and shape of the base plate 12 are the same as those of the transition plate 11. The base plate 12 is provided with bolt holes at positions corresponding to the plug welding holes of the transition plate 11....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com