Inner wallboard and its manufacturing method

A production method and technology for interior wall panels, which are applied in the processing of building materials, building materials, building components, etc., can solve the problems of troublesome construction, heavy weight, thick walls, etc., save raw materials and labor, enhance earthquake resistance, The effect of saving construction water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

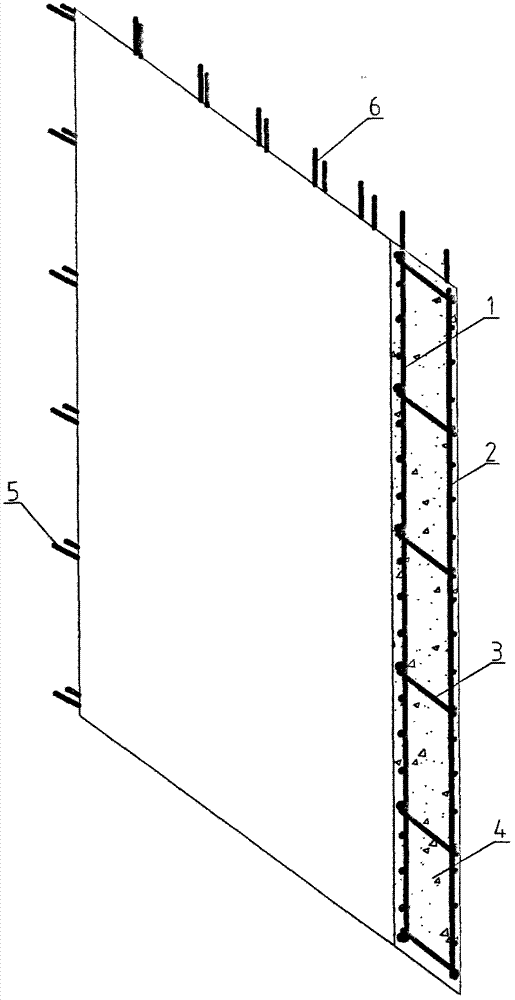

[0024] The upper layer of steel wire mesh 1 and the lower layer of steel wire mesh 2 are welded by warp and weft galvanized steel wires, and they are fixedly connected together by a steel column 3, which is a galvanized steel bar, and the upper layer of steel wire mesh 1 and Concrete 4 is fixedly connected between the steel wire mesh sheets 2 on the lower layer and on the outside. Concrete 4 is made by mixing cement, 5-10mm gravel, sand, fly ash, water, and water reducing agent. Both sides of the steel mesh sheet 1 and the lower layer of steel mesh sheet 2 are fixed with the protruding steel wire 5 at the side of the connecting plate, and at the upper end are fixed the protruding steel wire 6 at the top edge of the connecting plate, the protruding steel wire 5 at the side of the plate and the protruding steel wire at the top edge of the plate 6 is a galvanized steel bar with a length not less than 80mm.

[0025] The production method is:

[0026] 1), making mesh: the upper st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com