Large-volume anti-deformation steel cage and its binding method

A steel cage and anti-deformation technology, applied to artificial islands, structural elements, building components, etc., can solve the problems of large deformation due to self-weight, difficulty in meeting design and construction requirements, large structural size and heavy weight of steel cages, etc., and achieve molding rate High, improve the overall binding quality, and ensure the effect of binding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

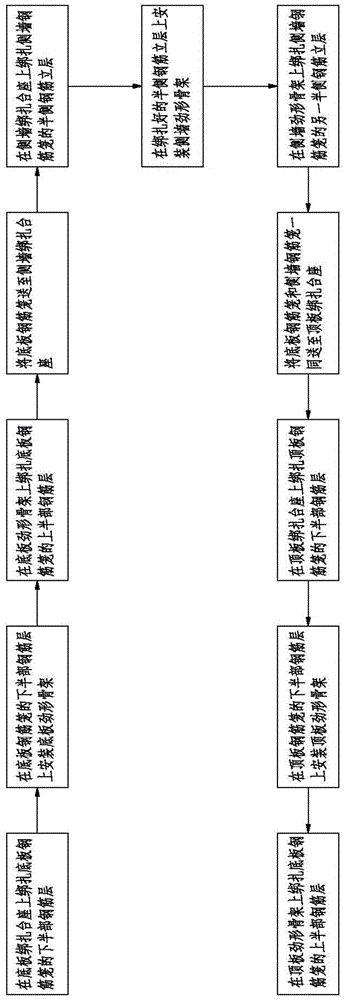

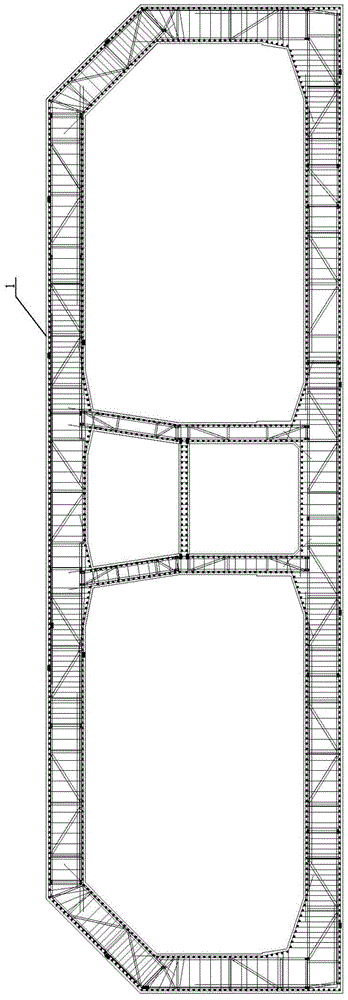

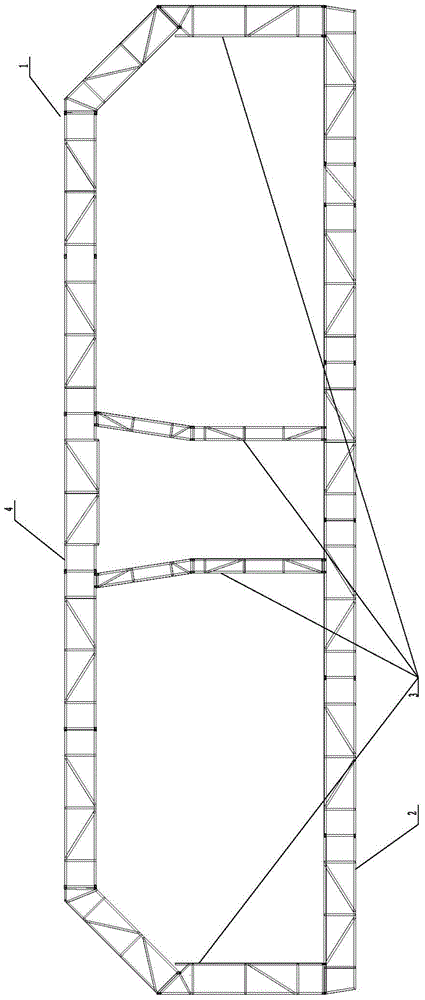

[0034] see figure 1 (direction of the arrow is the pushing direction of the reinforcement cage), a kind of large volume anti-deformation reinforcement cage binding method of the present invention may further comprise the steps:

[0035] 1. Bind the lower half of the steel reinforcement cage of the bottom plate on the bottom plate binding pedestal;

[0036] 2. Vertically install the stiff skeleton of the floor on the lower half of the steel reinforcement layer of the bound floor reinforcement cage;

[0037] 3. Bind the upper half of the steel bar layer of the bottom plate reinforcement cage on the stiff frame of the bottom plate, so far, the lower half of the steel bar layer is combined with the upper half of the steel bar layer to form a bottom plate reinforcement cage; and form the opposite bottom plate reinforcement cage through the bottom plate stiff frame inner support. In this embodiment, the rigid skeleton of the bottom plate includes a plurality of bottom plate skelet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com