Air-cooled slag discharge pipe used for small and medium size circulating fluidized bed boiler

A circulating fluidized bed, small and medium-sized technology, used in fluidized bed combustion equipment, fuel burned in a molten state, combustion type, etc., to achieve uniform fluidization, low manufacturing cost, and easy layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

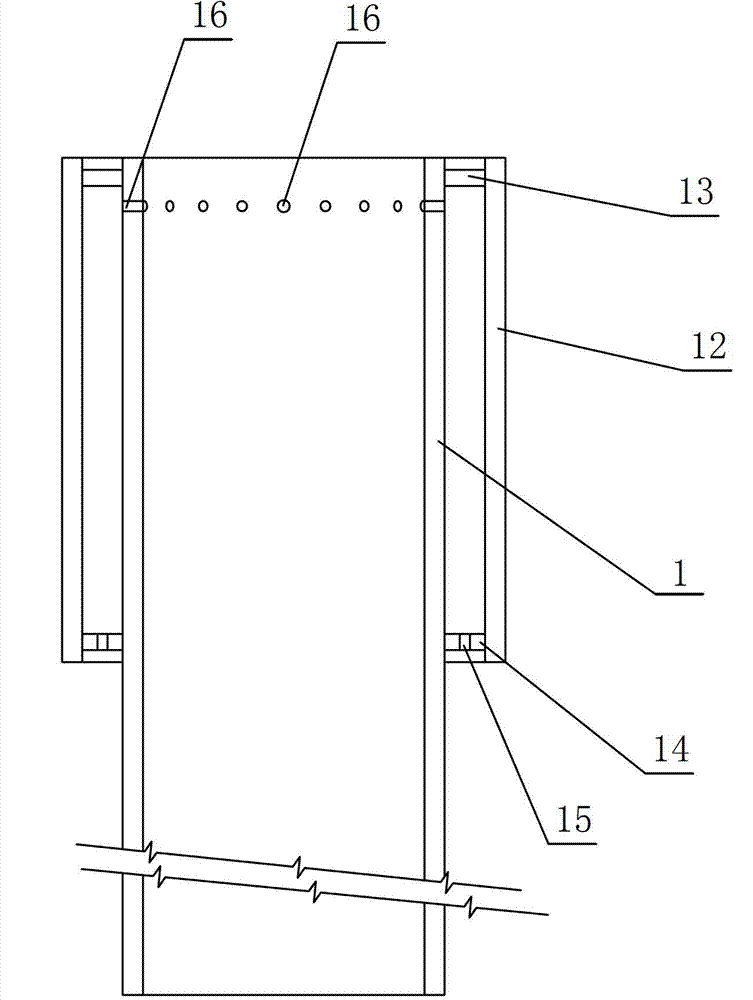

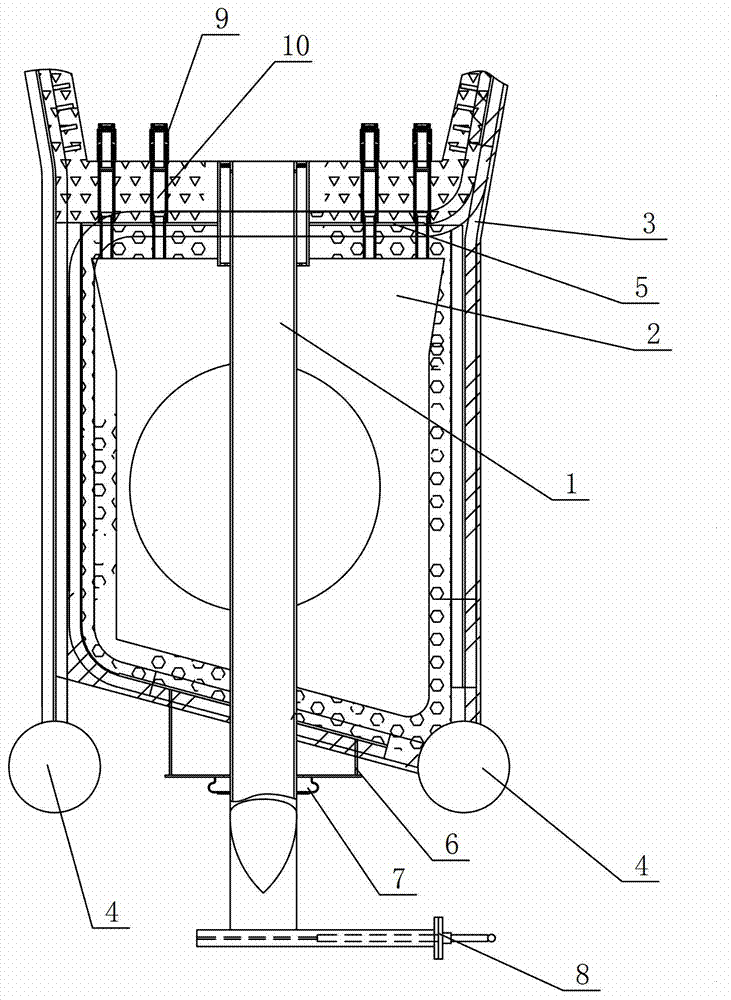

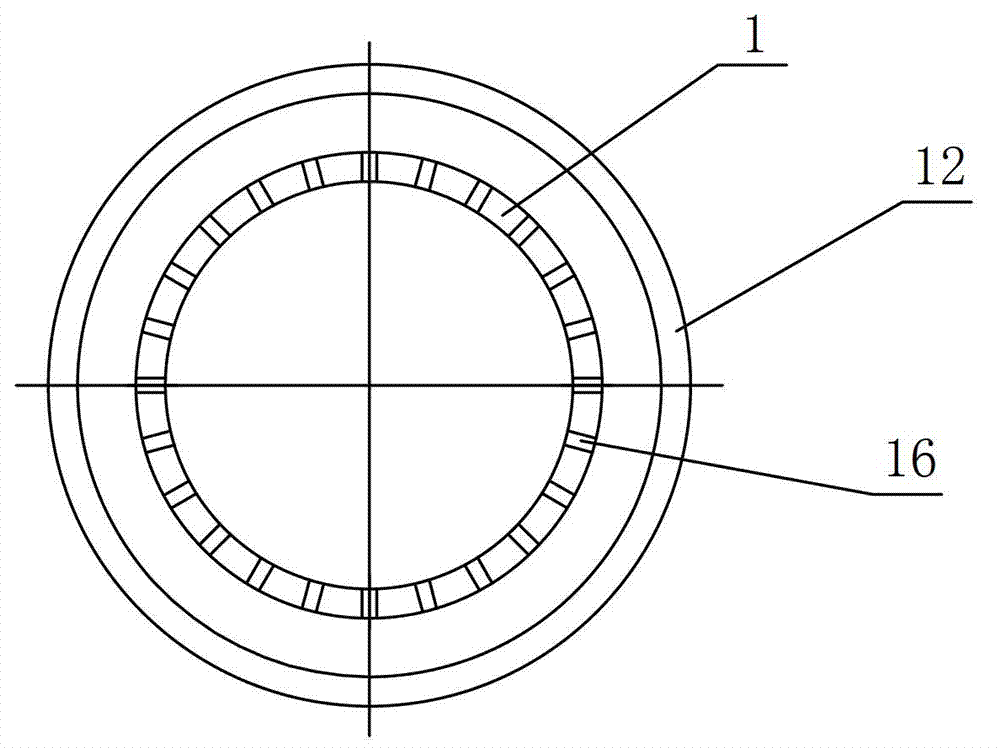

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0018] see Figure 1 to Figure 4 As shown, in this embodiment, an air-cooled slagging pipe for small and medium-sized circulating fluidized bed boilers includes a slagging pipe body 1 installed in the air chamber 2 of the furnace, and the air chamber 2 is composed of a water-cooled wall tube 3 is welded with the header 4 and the air distribution plate 5 to form a closed space, the upper end of the slag discharge pipe body 1 is welded and fixed with the air distribution plate 5, and the air distribution plate 5 is welded with the water-cooled wall pipe 3, and the The lower end of the slag discharge pipe body 1 protrudes from the air chamber 2 and is provided with a sealing case 6 , which is welded to the expansion joint 7 welded on the lower part of the sealing case 6 , and the end is welded to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com