Die for detecting stimulated battery

A technology for detecting molds and simulating batteries, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult to achieve end face and thread processing accuracy, uneven force on battery pole pieces, uneven charging and discharging, etc., to achieve good processing accuracy, It is convenient to analyze the reaction situation and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

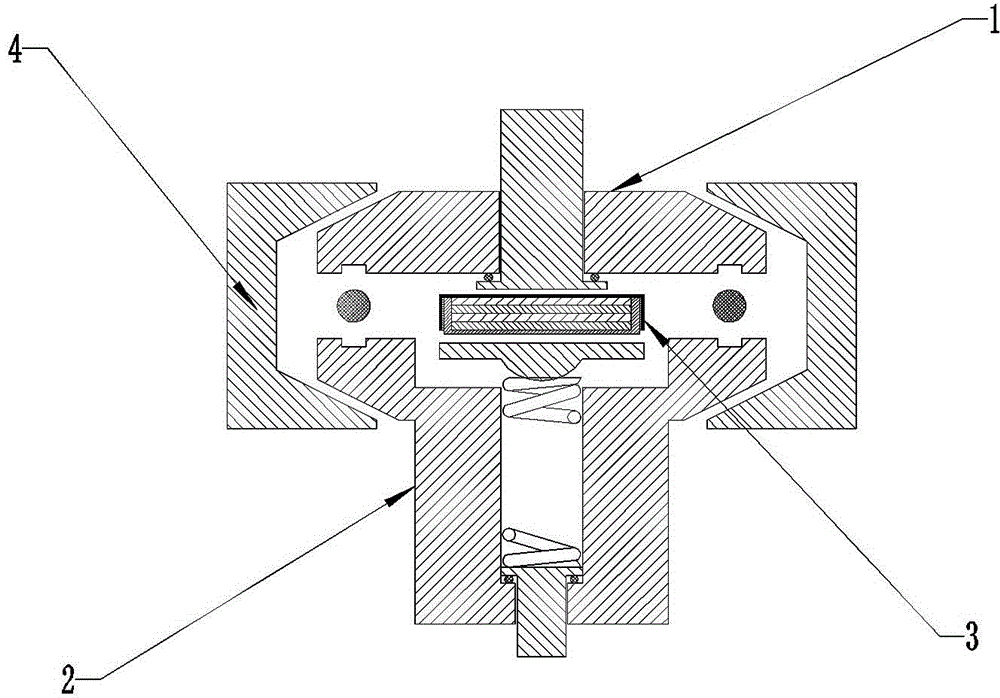

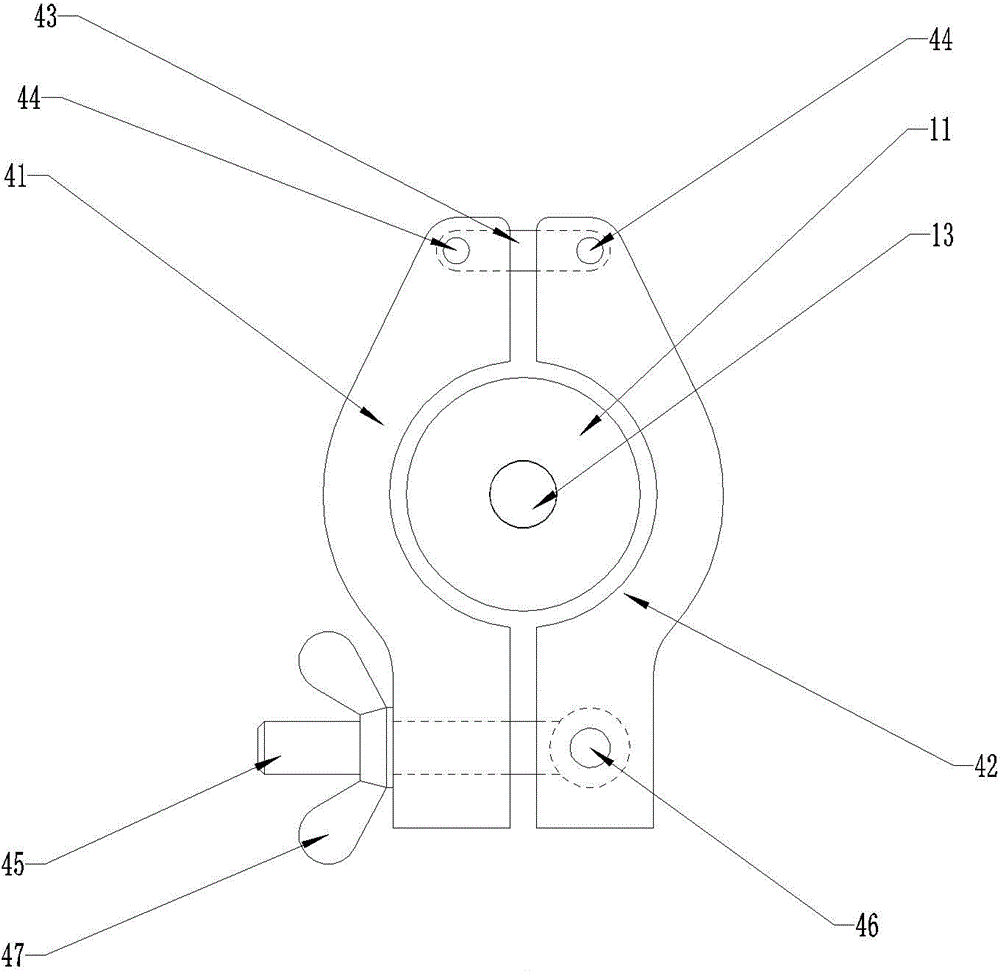

[0019] A simulation battery testing mold, such as figure 1 , figure 2 As shown, it is composed of an upper body 1, a lower body 2, a test cell 3, and a clamp 4, wherein: the test cell 3 is installed on the lower body 2, the upper body 1 is installed on the test cell 3, the clamp 4, the upper body The body 1 and the lower body 2 are connected into one body.

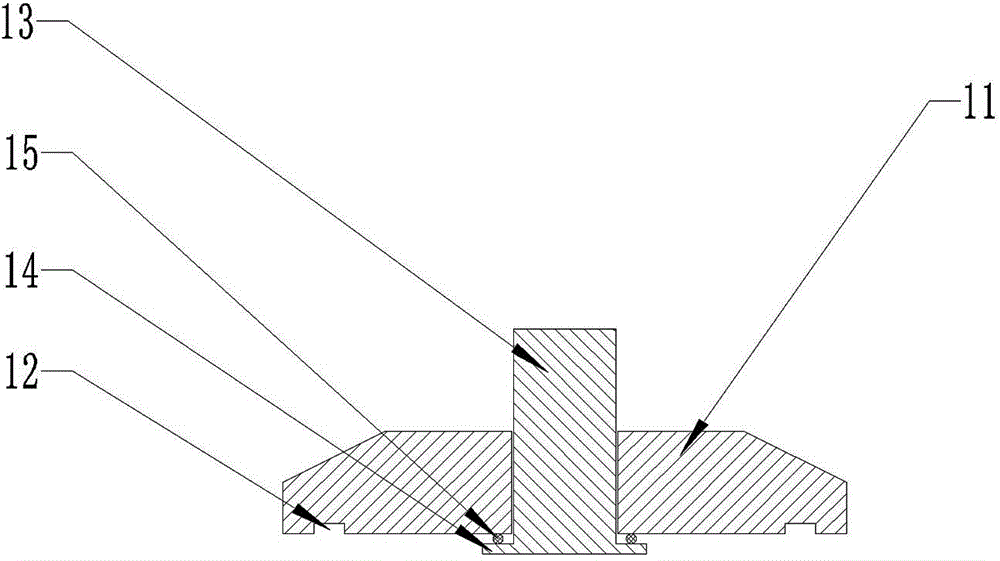

[0020] image 3 Shown is a schematic diagram of the structure of the upper body 1 in the present invention. The upper body 1 consists of an upper mold 11, an upper positioning groove 12, an upper electrode pressing block 13, an upper electrode pressing block boss 14 and an upper electrode pressing block insulating sealing ring 15 The upper positioning groove 12 is provided at the bottom of the upper mold 11, the upper electrode pressing block 13 is installed at the middle position of the upper mold 11, and the upper elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com