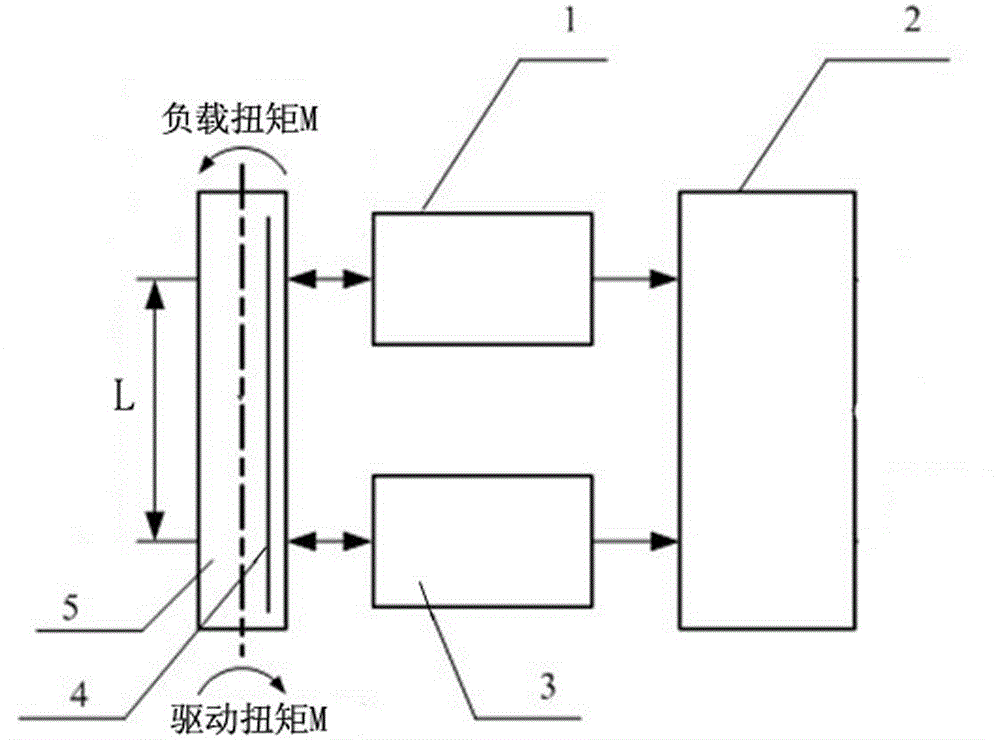

Method for testing photoelectric reflection type dynamic torque of equal-diameter rotary shaft

A technology of dynamic torque and photoelectric reflection, applied in the direction of torque measurement, measurement device, power measurement, etc., can solve the problems of complex structure of measurement device, limited test range, complex calculation model, etc., to improve operability and easy calculation , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

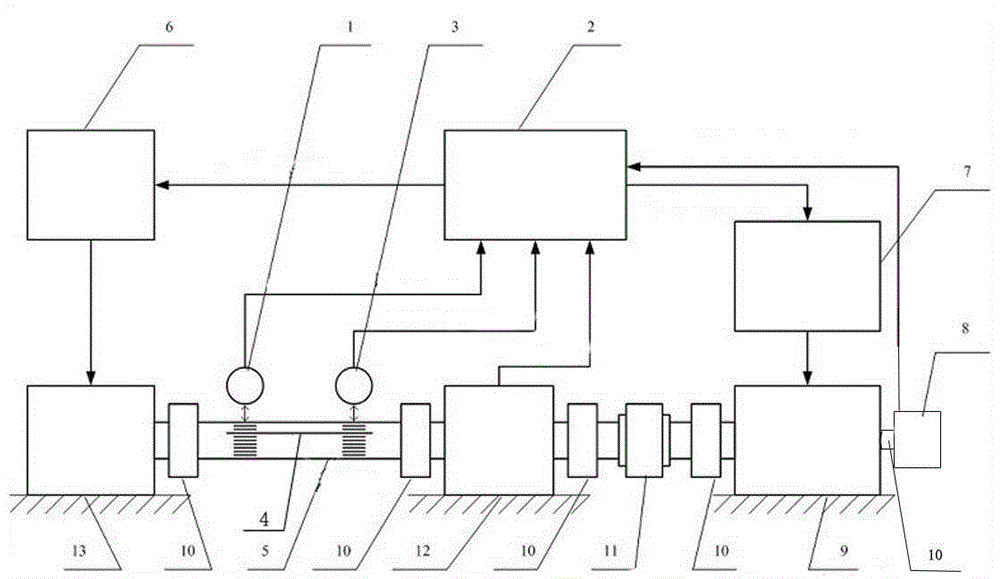

Method used

Image

Examples

Embodiment 1

[0024] The photoelectric reflective dynamic torque test method of the equal-diameter rotating shaft (only the first-order torsional vibration of the tested rotating shaft is tested), including the following steps:

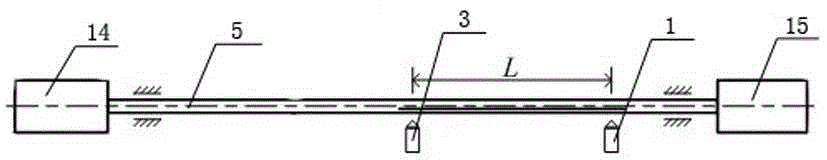

[0025] (1), build as image 3 The transmission system shown: select the measured rotating shaft 5 with a diameter of 0.1 m and a length of 5 m, the left end of the measured rotating shaft 5 is fixed with a steel rolling roll 14 with a diameter of 0.4 m and a length of 1 m, and the right end of the measured rotating shaft 5 is connected with the diameter 0.4m, a length of 1m motor rotor 15 is fixed. One side of the tested rotating shaft 5 is installed with a gap between the tested rotating shaft 5 and the light emitted by the light source is located on the first reflective photoelectric sensor 3 on the vibration node section of the tested rotating shaft 5 and between the tested rotating shaft 5 The gap between them is equal to the gap between the first reflective p...

Embodiment 2

[0032]The photoelectric reflective dynamic torque test method of the equal-diameter rotating shaft (only the first 2 orders of dynamic torque of the tested rotating shaft is tested), including the following steps:

[0033] (1) Construct the transmission system as in Example 1.

[0034] (2) When the tested rotating shaft 5 is running with a load, it will generate static torque under the action of the load torque; when the tested rotating shaft 5 is excited by broadband excitation from the power source or load torque, it will produce n-order sinusoidal changes Torsional vibrations create dynamic torque. Under the action of static and dynamic torque, a dynamic relative rotation angle θ will be generated between the vibration node section of the measured rotating shaft 5 and the detection section, so that the dynamic signal intelligent test analysis system 2 detects the first reflective photoelectric sensor 3 and the second The time difference τ generated between the photoelectri...

Embodiment 3

[0042] The photoelectric reflective dynamic torque test method of the equal-diameter rotating shaft (only the first three orders of dynamic torque of the tested rotating shaft is tested), including the following steps:

[0043] (1) Construct the transmission system as in Example 1.

[0044] (2) When the tested rotating shaft 5 is running with a load, it will generate static torque under the action of the load torque; when the tested rotating shaft 5 is excited by broadband excitation from the power source or load torque, it will produce n-order sinusoidal changes Torsional vibrations create dynamic torque. Under the action of static and dynamic torque, a dynamic relative rotation angle θ will be generated between the vibration node section of the measured rotating shaft 5 and the detection section, so that the dynamic signal intelligent test analysis system 2 detects the first reflective photoelectric sensor 3 and the second The time difference τ generated between the photoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com