Camera-based code reader and method of calibrated manufacturing the same

A code reader and camera technology, applied in the direction of instruments, computer parts, electromagnetic radiation induction, etc., can solve the problem of high system weight, achieve high calibration accuracy, lower cost, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

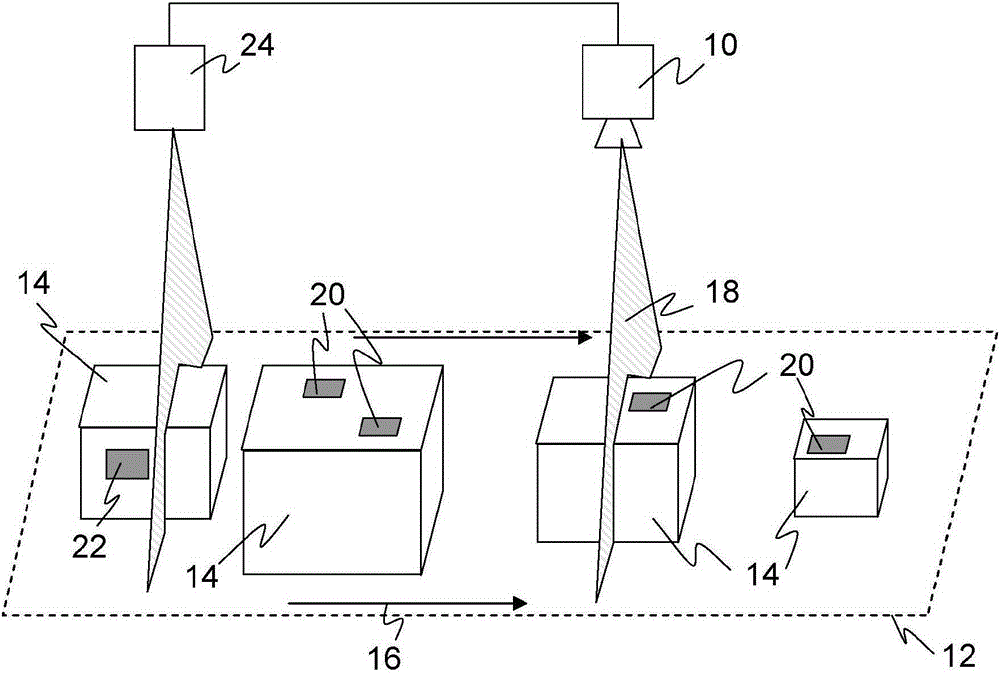

[0041] figure 1 A code reader 10 is shown mounted above a conveyor belt 12 on which objects 14 are conveyed through an acquisition area 18 of the code reader 10 as indicated by arrow 16 . The object 14 carries a code field 20 on its outer surface. The tasks of the code reader 10 are: to identify the code field 20; to read the code displayed thereon; to decode; and, to classify the object 14 to which each code belongs.

[0042] The code region 20 can only be recognized by the code reader 10 when the code region 20 is arranged on the upper surface or is at least visible from above. figure 1 The illustrated plurality of code readers 10 , which can be used for irregularly reading codes 22 arranged on the side or under an object, are mounted from different directions, so that so-called omnidirectional reading can be performed from all directions. Arranging a plurality of code readers 10 to form a reading system is in practice mostly realized as a reading tunnel.

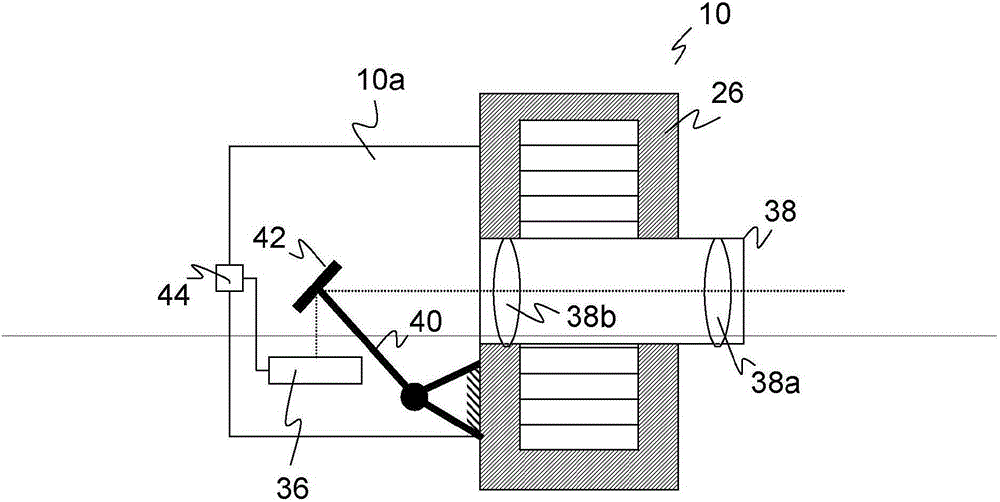

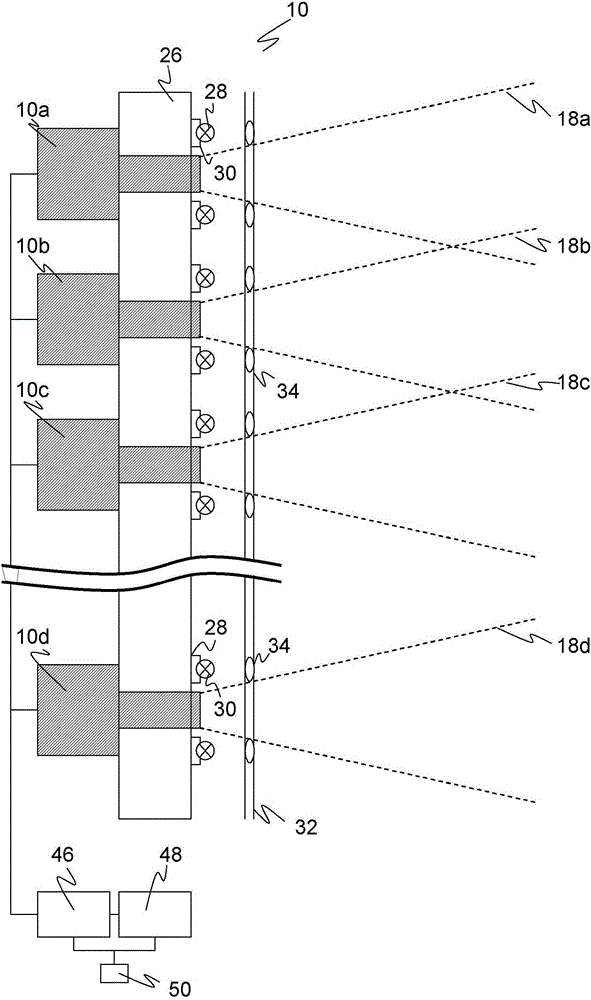

[0043] as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com