Linear constant-current and current-sharing LED drive circuit and circuit board structure thereof

An LED drive, linear constant current technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of troublesome after-sales service of products, lack of interchangeability of products, inability to adapt to matching, etc., and achieve a high degree of interchangeability , Improve control flexibility, reduce power consumption and heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

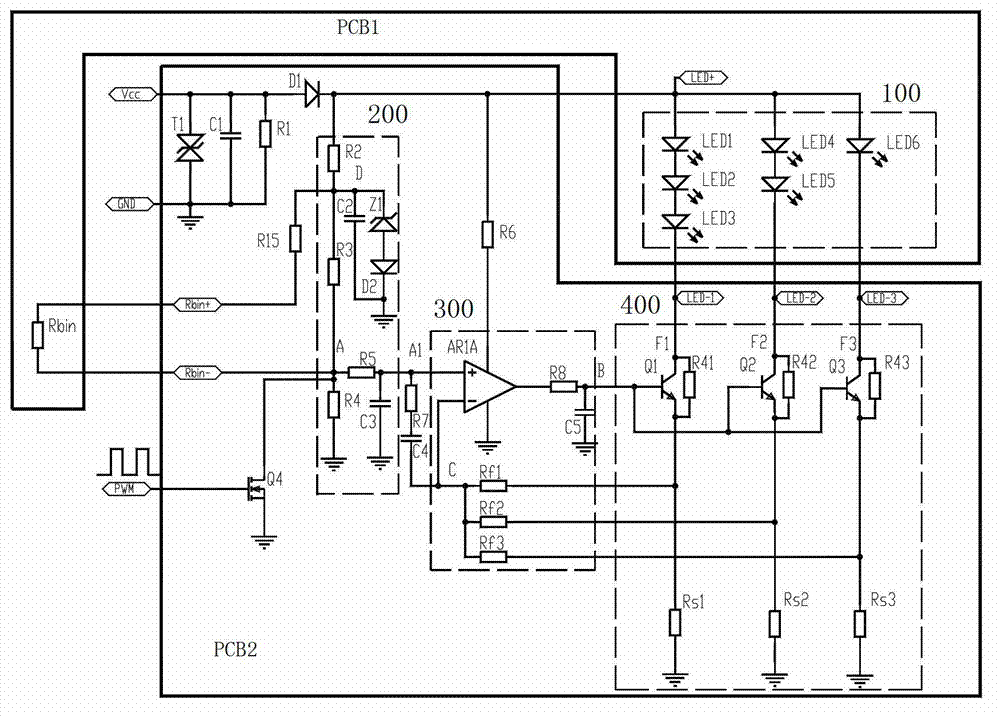

[0029] The linear constant current equalizing LED driving circuit of the present invention is used to provide a balanced and stable driving current for the multi-channel LED light-emitting module 100. The multi-channel LED light-emitting module 100 includes at least two LED strings, and each LED string contains at least one LED. LED elements connected in series. Limited by the working voltage, usually the number of LEDs connected in series in each LED string is ≤3. exist figure 1 In the shown embodiment, the multi-channel LED lighting module 100 includes 3 LED strings, the input voltage Vcc passes through the anti-surge and filter circuit composed of TVS tube or transient voltage suppression diode T1, capacitor C1 and resistor R1, and passes through the anti-reverse The diode D1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com