A-mode ultrasonic elastic imaging system based on mechanical scanning and method thereof

A mechanical scanning and imaging system technology, applied in echo tomography and other directions, can solve the problems that the tissue of interest cannot be accurately detected, the mechanical scanning positioning accuracy is low, and the axial resolution is not high enough, achieving a high degree of freedom and practicality. Strong performance and good imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

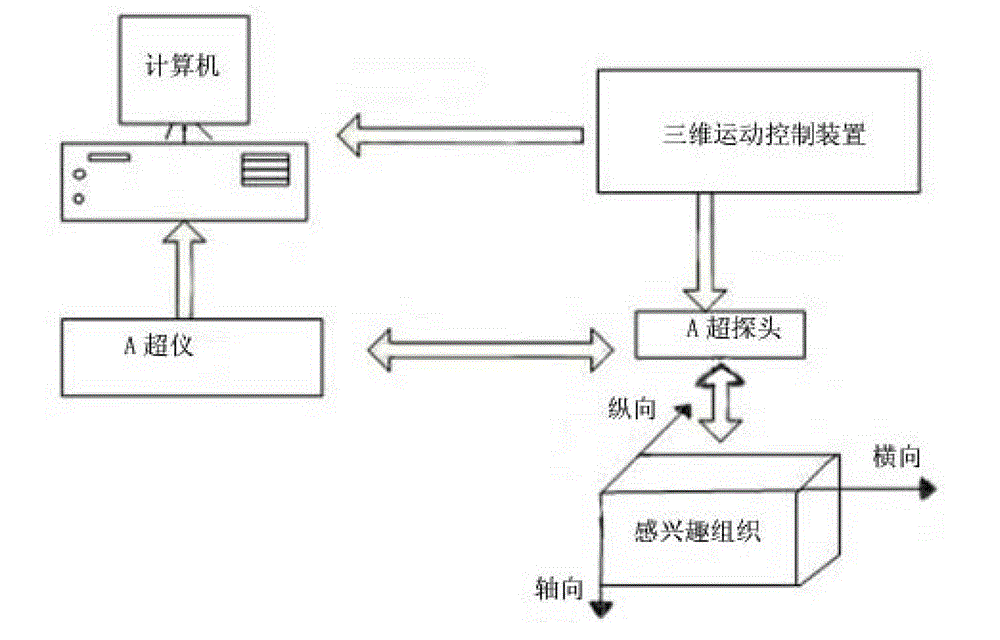

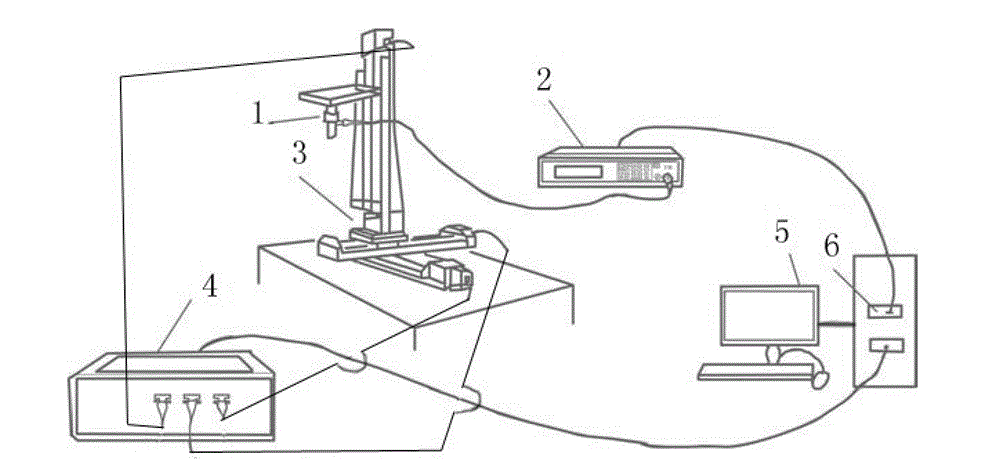

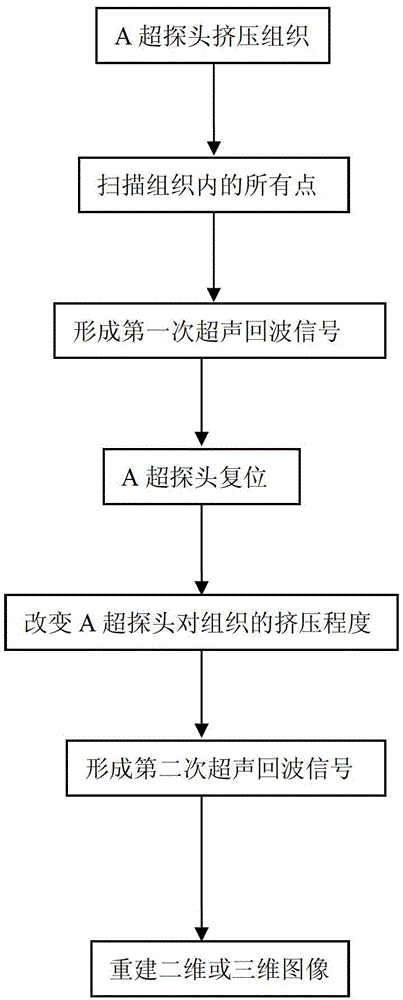

[0038] Such as figure 1 and figure 2 As shown, a mechanical scanning-based A superelastic imaging system includes a three-dimensional motion control device, an A-ultrasonic probe 1, an A-ultrasound instrument 2 and a computer that are electrically connected in turn, and the computer includes a display 5 and a host computer 6. The three-dimensional The motion control device includes a console 3 and a control box 4 , and the control box 4 is connected to a host computer 6 .

[0039] The control box 4 has output terminals in three directions of movement of X, Y and Z axes, and the console 3 has input terminals in three directions of movement of X, Y and Z axes. The X, Y and Z axes of the control box 4 The Z-axis output ends are respectively connected to the console X, Y and Z-axis input ends, the output ends are connected to the input ends through lead wires, the console has a stepping motor, and the bottom of the console is provided with a shock absorber, so The console inclu...

Embodiment 2

[0055] Such as figure 1 and figure 2 Shown, a kind of A superelasticity imaging system based on mechanical scanning comprises three-dimensional motion control device, A supersonic probe 1, A supersonic instrument 2 and computer that are electrically connected in turn, and said computer includes a monitor 5 and a host computer 6 connected to each other, The three-dimensional motion control device includes a console 3 and a control box 4 , and the control box 4 is connected to a host computer 6 .

[0056] The control box 4 has output terminals in three directions of movement of X, Y and Z axes, and the console 3 has input terminals in three directions of movement of X, Y and Z axes. The X, Y and Z axes of the control box 4 The Z-axis output ends are respectively connected to the console X, Y and Z-axis input ends, the output ends are connected to the input ends through lead wires, the console has a stepping motor, and the bottom of the console is provided with a shock absorber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com