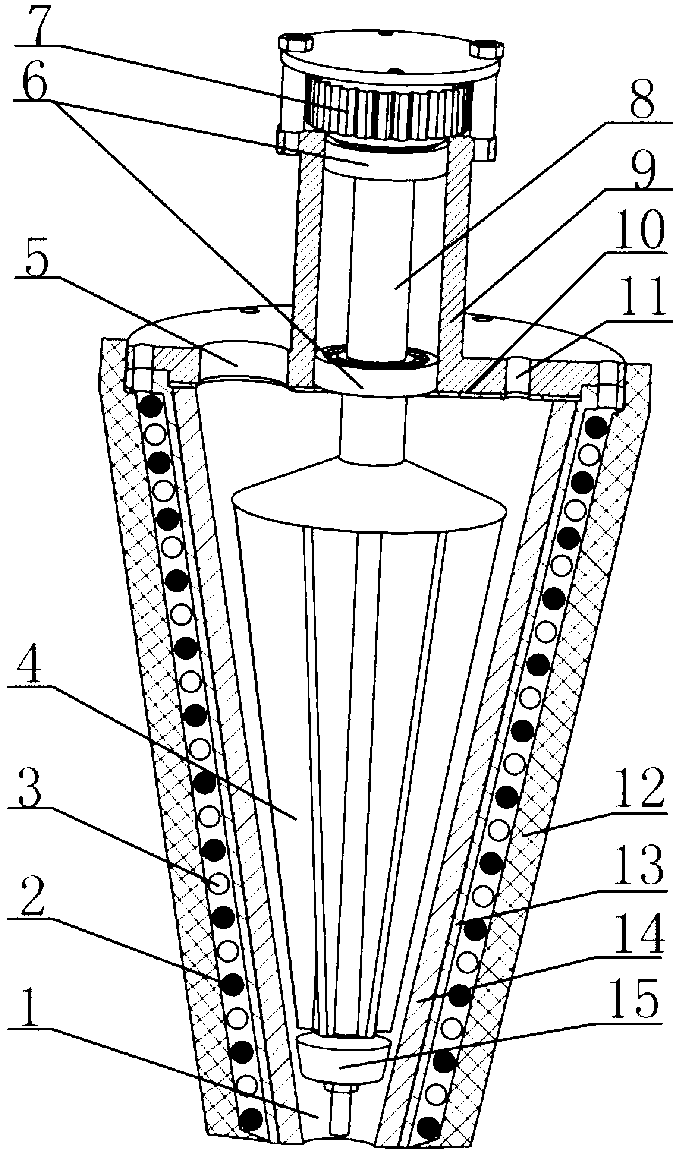

Continuous production device for semisolid slurry

A technology of semi-solid slurry and preparation equipment, which is applied in the field of semi-solid metal processing to achieve the effects of uniform distribution, simple operation and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] (1) The liquidus line of the ZL101A aluminum alloy used in the test is 615°C. Melt the alloy in a crucible resistance furnace. When the temperature of the alloy reaches about 720°C, use a bell jar to press the dried hexachloroethane into the melt The lower part (the addition amount is 0.5% of the total weight of the alloy liquid) is gently shaken to carry out the degassing and slag removal refining treatment of the alloy melt, and finally the temperature of the alloy melt is lowered to 630°C for heat preservation.

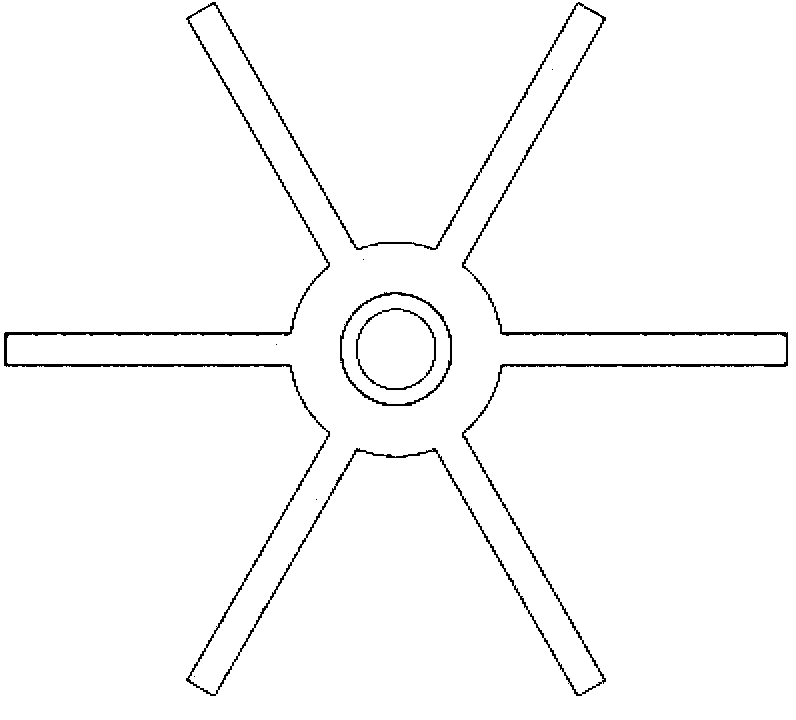

[0022] (2) Set the temperature of the stirring chamber of the device of the present invention to 590°C, turn on the speed-regulating motor to make the rotating speed of the stirring screw rod 500rad / min, control the graphite blockage at a certain height, and after the parameters reach the set value, smelt the previous step The alloy liquid is poured into the mixing chamber of the device of the present invention through the feed port, and the amount of poured ...

example 2

[0024] (1) The liquidus temperature of the 7075 aluminum alloy used in the test is 640°C. Put the aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 400°C. After the temperature of the alloy liquid reaches 720°C, it is refined. Press the dried hexachloroethane into the lower part of the melt (the amount added is 0.5% of the total weight of the alloy liquid), and shake it gently to degas the alloy melt, remove slag and refine it, and finally melt the alloy Body temperature dropped to 650°C for heat preservation.

[0025] (2) Set the temperature of the stirring chamber of the device of the present invention to 600°C, turn on the speed-regulating motor to make the rotating speed of the stirring screw rod 500rad / min, and after the parameter reaches the set value, pass the molten alloy melted in the previous step through the feed port to continue Pour into the stirring chamber of the device of the present invention, pour into the alloy amount a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com