Rolling roll dismantling mechanism for battery pole piece rolling machine

A battery pole piece and rolling roller technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in replacement, waste of time and manpower, and heavy weight of rolling rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

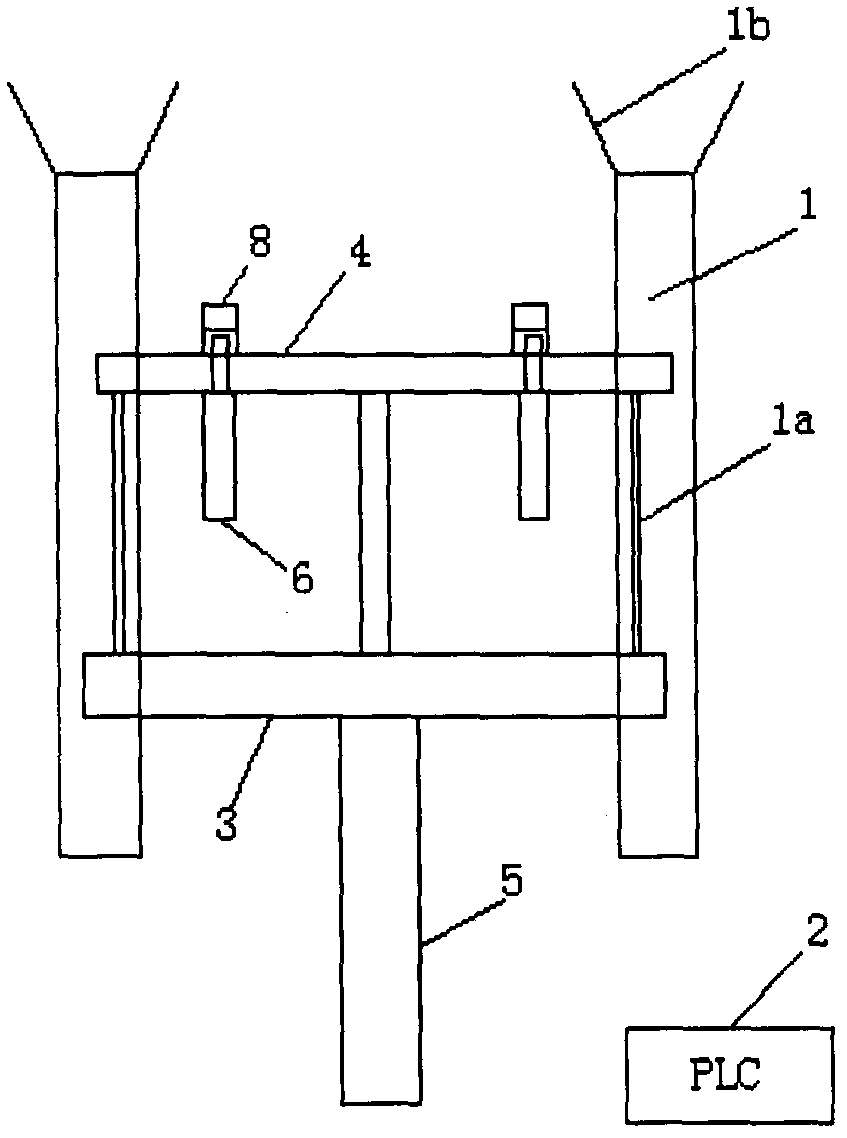

[0012] Such as figure 1 , figure 2 As shown, the rolling roller removal mechanism for the battery pole piece rolling machine includes two supporting feet 1 and a PLC control device 2, a crossbeam 3 and a moving beam 4 are arranged between the supporting feet 1, and the two supporting feet 1 There are guide rails 1a on each of them, the moving beam 4 is slidingly matched with the guide rail 1a, the end of the support foot 1 is provided with positioning claws 1b, the driving device on the beam 3 is connected with the moving beam 4, and the moving beam 4 is provided with two clamping Mechanism, the PLC control device 2 is connected and controlled with the clamping mechanism and the driving device.

[0013] Described driving device is oil cylinder 5.

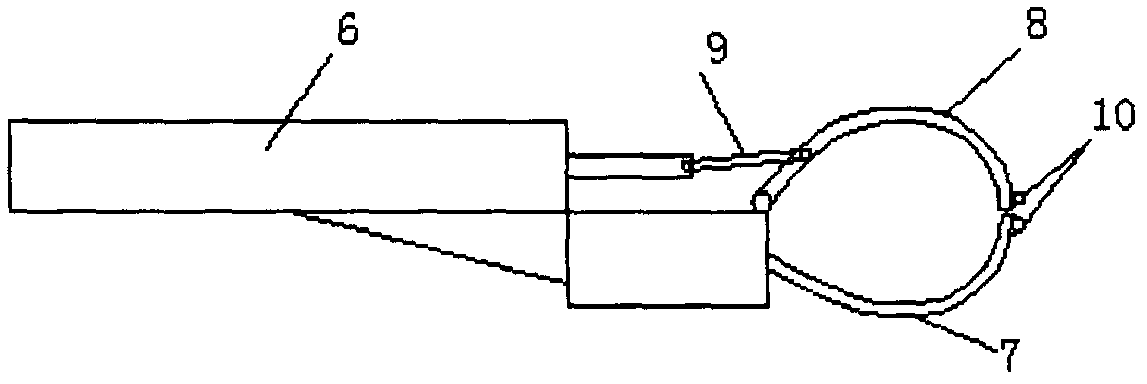

[0014] The clamping mechanism includes a cylinder 6, a fixed jaw 7, a moving jaw 8 and a connecting rod 9, the fixed jaw 7 is fixed on the moving beam 4, the moving jaw 8 is hinged on the moving beam 4, and the cylinder 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com