Sliding valve tool for twin-screw compressor and sliding valve processing method

A twin-screw and compressor technology, which is applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of high failure rate, low matching accuracy between the herringbone arc surface and the screw, and the reduction of the herringbone arc surface of the slide valve. Processing accuracy and other issues to achieve the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

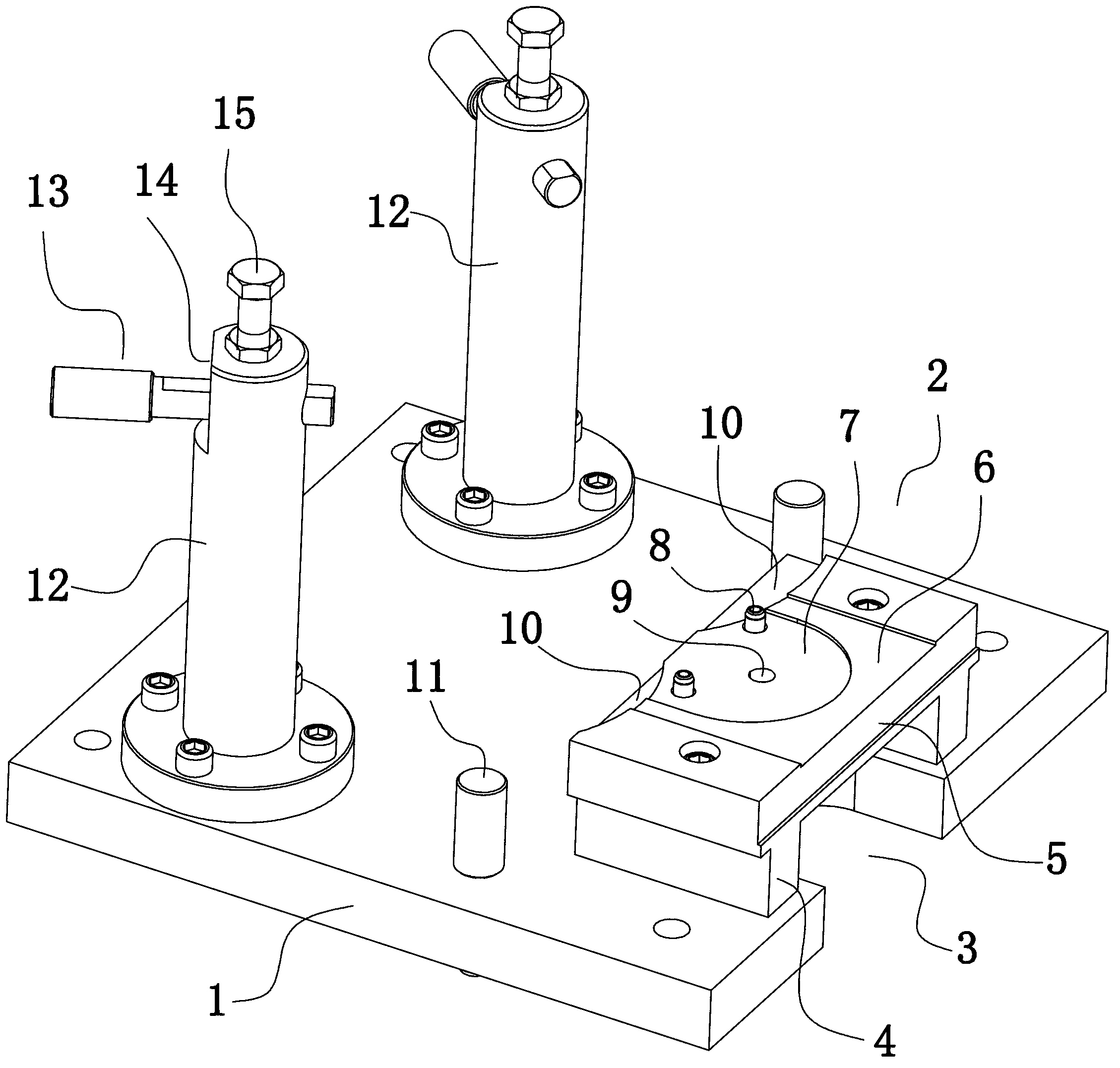

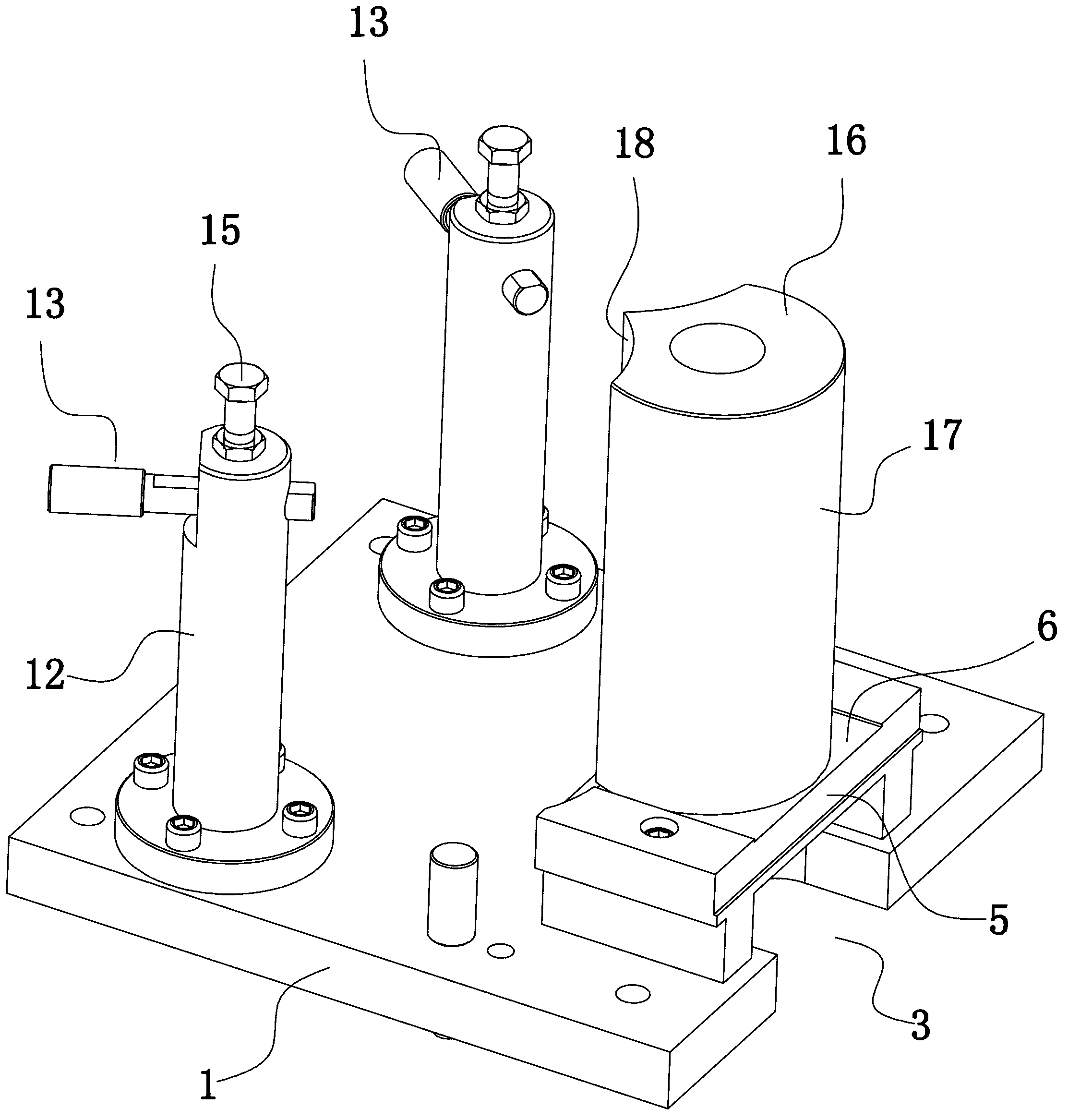

[0045] Embodiment 1: as figure 1 , figure 2 As shown, a sliding valve tooling for a twin-screw compressor includes a bottom plate 1, a fixing structure 2 arranged on one side of the upper surface of the bottom plate for positioning and fixing the sliding valve 16, and two columns on the other side of the upper surface of the bottom plate 12. The upper surface of the bottom plate 1 is provided with two alignment holes penetrating the bottom plate, and an alignment pin 11 is arranged in the alignment holes. The column 12 is cylindrical, and the column is fixed on the base plate by bolts. The top of the side of the column 12 is provided with a first section 14 parallel to the axis of the column. Guide holes are respectively provided on the sides of the two columns 12 . The guide hole is a round hole. The guide hole extends radially along the column 12 and a port of the guide hole is disposed on the first section 14 . Slidably provided with table pin 13 in the guide hole. ...

Embodiment 2

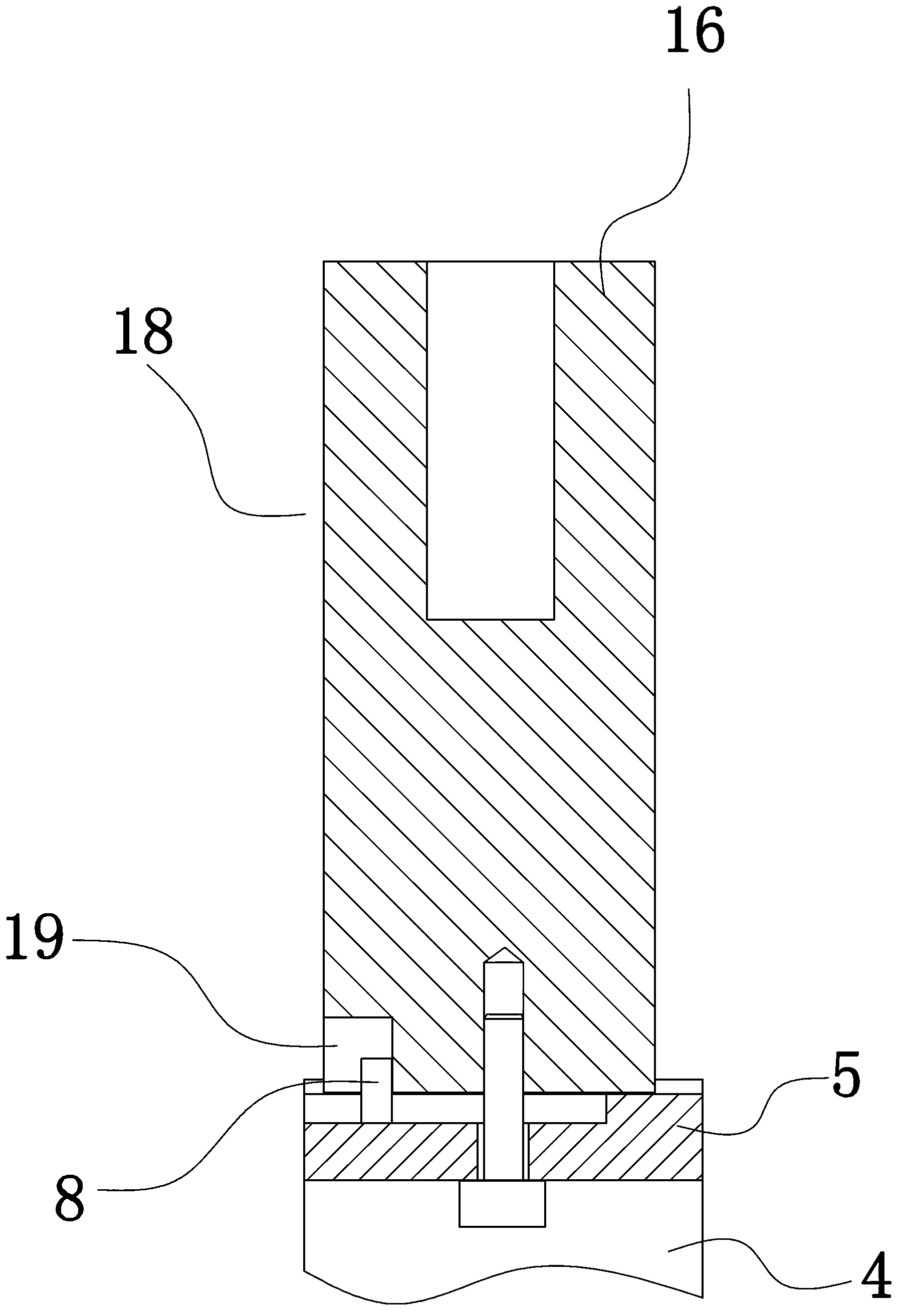

[0052]Embodiment 2: A slide valve processing method. This embodiment uses the slide valve tooling of the twin-screw compressor in Embodiment 1 to install and fix the slide valve; the slide valve processing method in this embodiment is suitable for sliding valves with herringbone The fine boring process of the arc surface 18, and the outer circular surface 17 and the end face of the slide valve have been finished. The slide valve processing method of the present embodiment comprises the following steps:

[0053] A: If figure 2 , Figure 4 As shown, the slide valve is fixed on the base plate through the fixing structure, and the base plate is fixed on the processing platform of the CNC machine tool. When the slide valve is installed on the bottom plate, one end face of one pair of table pins faces an arc surface in the herringbone arc surface of the slide valve, and one end face of the other pair of table pins faces the herringbone arc surface of the slide valve. Another arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com