On-line direct-current motor grinder

A DC motor and grinder technology, applied in the grinder field, can solve the problems of poor spark commutation, long troubleshooting time, and high maintenance costs, and achieve the effects of short troubleshooting time, good grinding effect, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

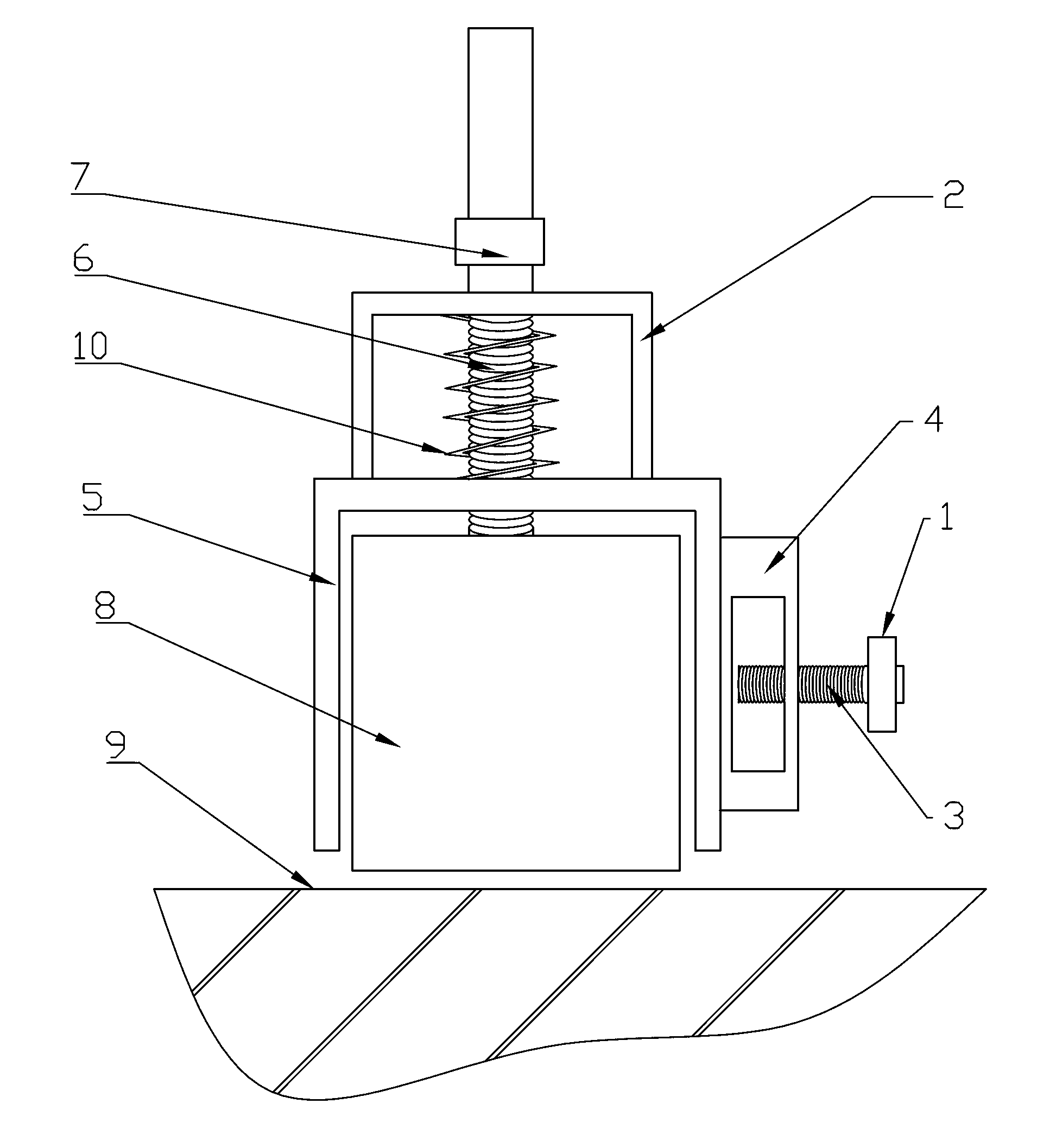

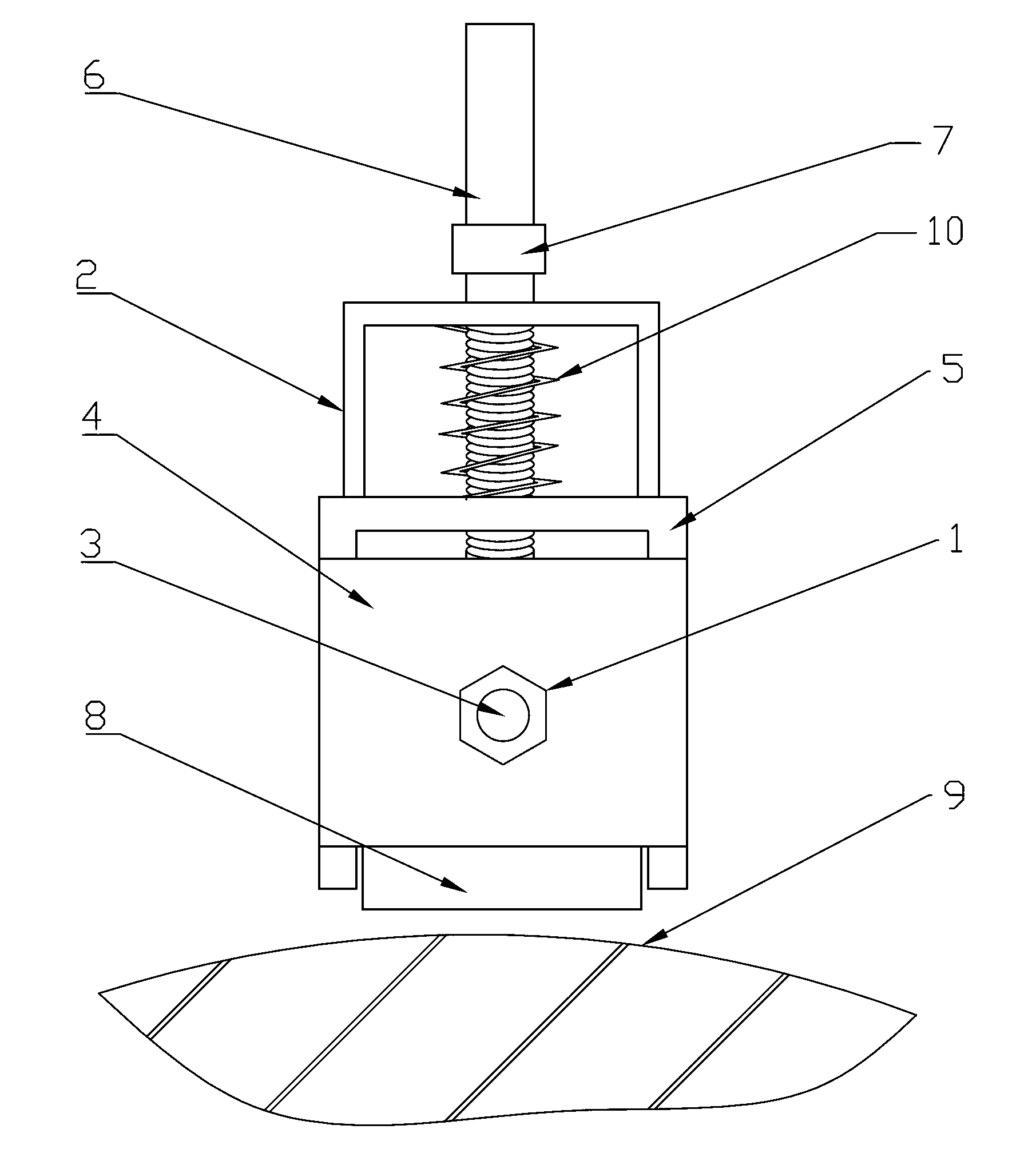

[0013] Such as figure 1 , figure 2 As shown, an online DC motor grinder of the present invention includes a grinder body and a fixing device, the fixing device is arranged on one side of the grinder body, and the grinder body includes a bracket, an adjusting screw 7, an adjusting wire Rod 6 and grinding stone 8, described support comprises upper support 2 and lower support 5, described grinding stone 8 is arranged in the lower support 5, and its bottom stretches out lower support 5, and described adjusting screw rod 6 one ends and grinding The stone 8 is fixedly connected, and the other end passes through the lower bracket 5 and the upper bracket 2 respectively, and is fixed by the adjusting screw 7. The fixing device includes a fastening block 4 and a fixing screw 3, and the fastening block 4 is arranged on the lower bracket 5, one end of the fixing screw 3 is connected with the fastening block 4, and the other end is connected with the brush rod of the electric brush throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com