Independent multi-cylinder, isobaric and synchronous hydraulic injection molding system for semiconductor plastic packaged mould

A plastic sealing mold and injection molding system technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of loose filling, unacceptable, pores, etc., and achieve the effect of simplifying the structure, reducing the defects of pores, and reducing the cost of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

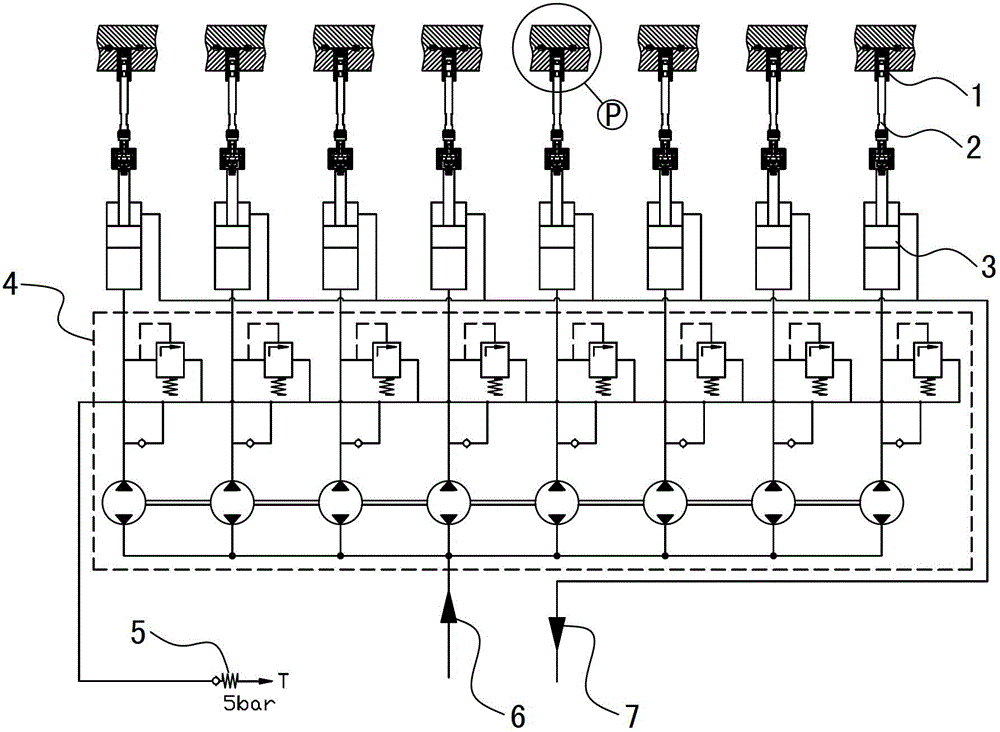

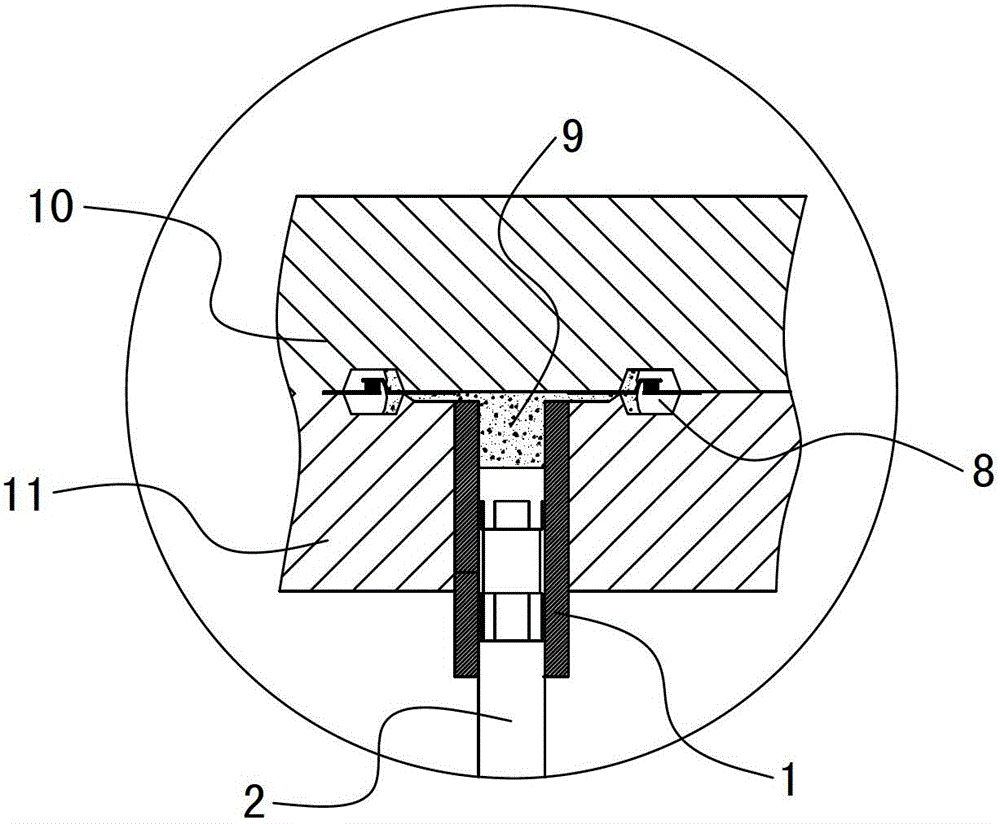

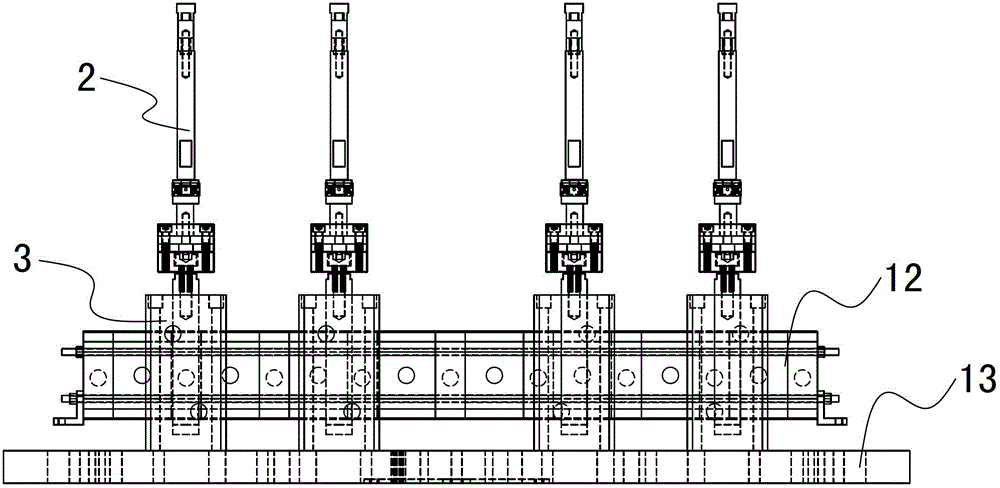

[0024] a kind of like figure 1 , 3 The independent multi-cylinder, equal pressure, and synchronous hydraulic injection molding system of the semiconductor plastic sealing mold shown in . Reciprocating hydraulic drive, wherein the injection heads 2 are respectively connected to an independent cylinder 3, and all the independent cylinders 3 are synchronously driven.

[0025] A plurality of independent oil cylinders 3 driven synchronously correspond to the injection heads 2 respectively. From the principle of hydraulic transmission, it can be seen that the pressure of the injection head 2 on the epoxy molding compound in the molding barrel 1 is exactly the same. The amount of epoxy molding compound is inconsistent, so that there is a slight difference in the ideal height of the molding compound cake. At this time, the injection head 2 will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com