Packaging bottle cap

A technology of packaging bottle caps and mutual cooperation, which is applied in the directions of packaging, transportation and packaging, and capping with auxiliary devices, etc., which can solve the problems of time-consuming and water-consuming, poor cleaning ability of cleaning agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

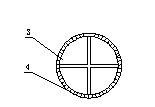

[0014] The present invention comprises upper cover 1 and lower cover 2 that cooperate with each other, and upper cover 1 is provided with safety ring; There is a liquid storage part on the lower side of the cutting part 3, and the liquid storage part includes two interconnected annular liquid storage chambers, the upper liquid storage chamber 5 is arranged in the lower cover 2, and the lower liquid storage chamber 6 closes the lower opening of the lower cover 2 .

[0015] The operation steps of the present invention are as follows: when in use, first unscrew the entire bottle cap, pour the cleaning agent into the clothes to wash the clothes; The push plate drives the cutting part 3 to move down. When the cutting teeth 4 of the cutting part 3 touch the upper liquid storage chamber 5, the upper liquid storage chamber 5 is cut open. At this time, the defoamer in the liquid storage part can be poured out for use. In the present invention, after the defoamer in the liquid storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com