Continuous microwave kiln for producing enrich titanium materials and method for preparing enrich titanium materials thereof

A titanium-rich material and microwave kiln technology, applied in chemical instruments and methods, improvement of process efficiency, solid separation, etc., can solve problems such as pollution and high energy consumption, and achieve uniformity and stability, convenient maintenance, microwave energy The effect of high usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

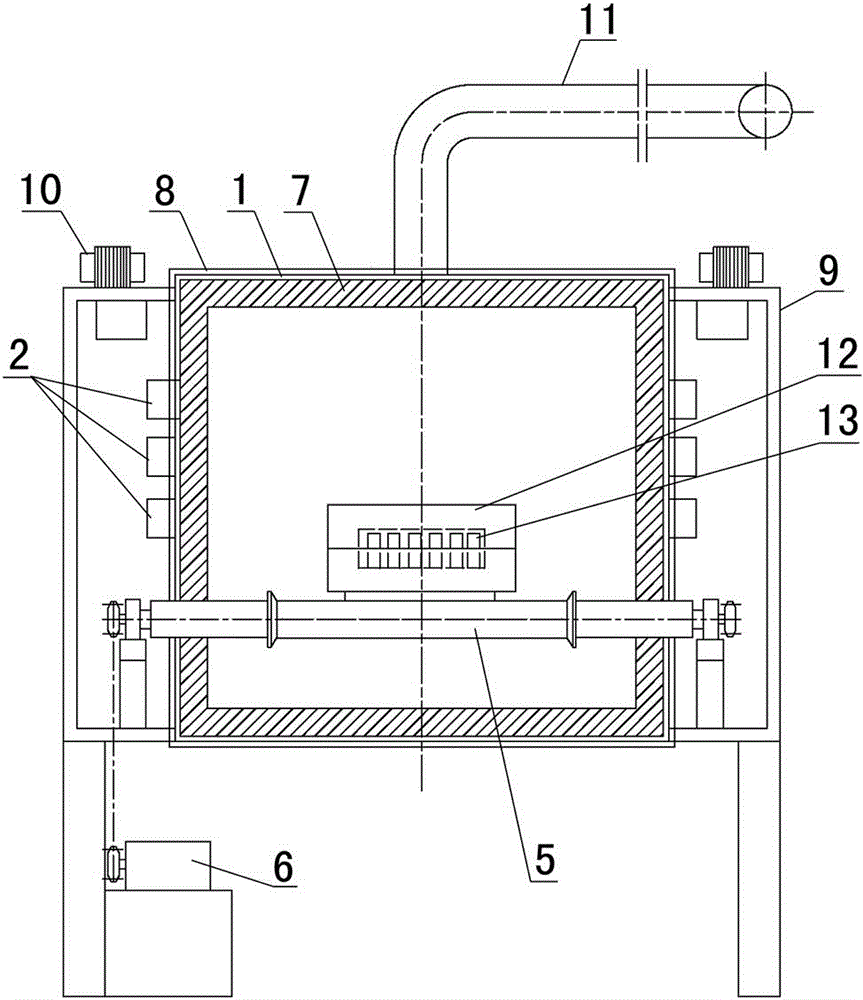

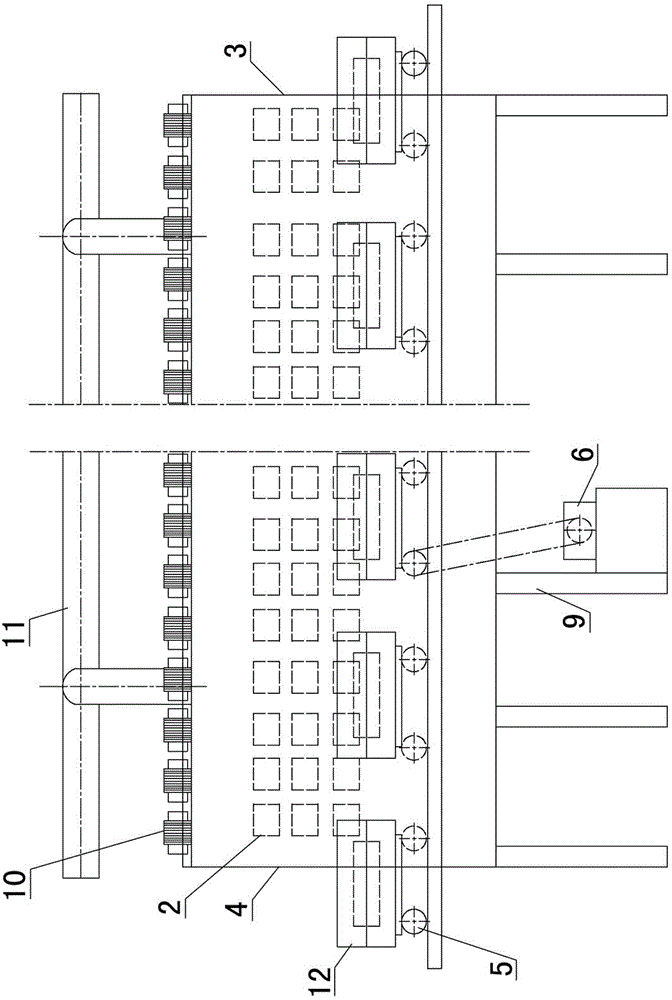

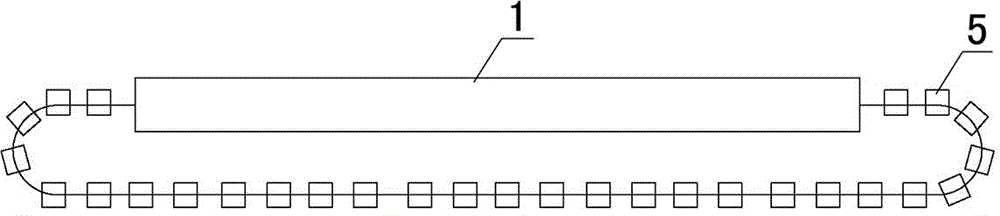

[0035] Examples see Figure 1-3 , this continuous microwave kiln for producing titanium-rich materials includes a kiln body 1, a magnetron 2, a conveying roller table 5, a roller table drive motor 6, a transformer and ancillary electrical components 10, and the kiln body 1 is arranged laterally and Placed on the kiln body support 9, one end of the kiln body 1 is provided with a feed port 3, and the other end is provided with a discharge port 4, the top of the kiln body 1 is connected with the exhaust pipe 11, and the inner wall of the kiln body 1 is provided with The heat preservation protective layer 7, the outer wall of the kiln body 1 is provided with a water-cooled interlayer 8.

[0036]The structure of the kiln body 1 is verified by a large number of experiments and production: the wall of the kiln body is painted with protective materials (ie, the thermal insulation layer 7), and the wall of the kiln body is additionally equipped with a circulating water cooling jacket (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com