Cathode protection system for underground pipeline system

An underground pipeline and cathodic protection technology, applied in the field of underground pipeline protection, can solve the problems of long construction period, damage, pitting corrosion, etc., achieve huge economic value and social value, high technical maturity, and easy construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

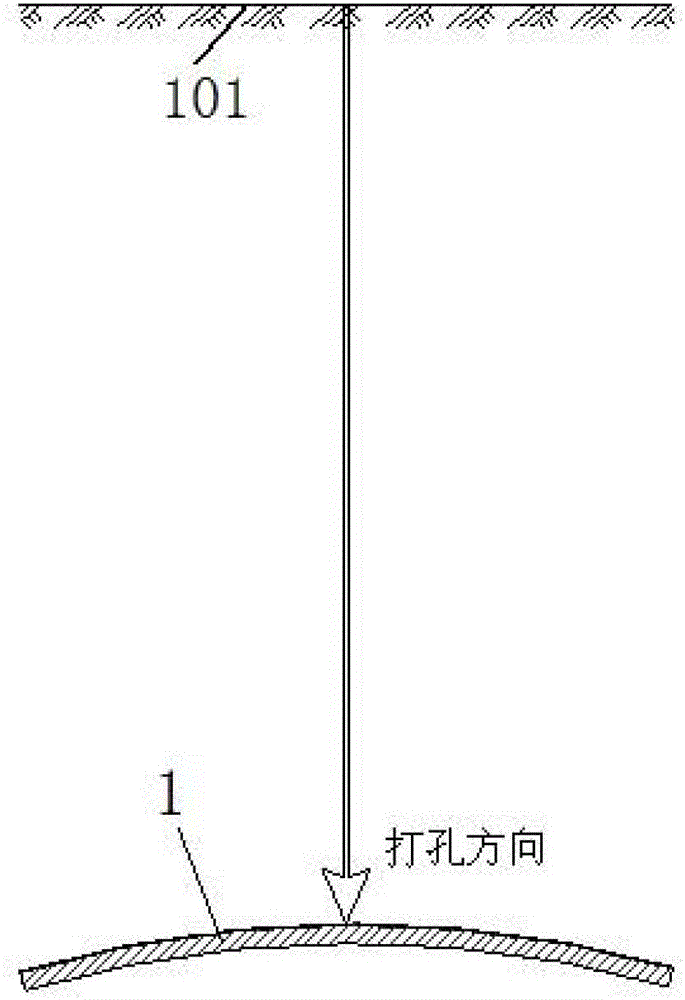

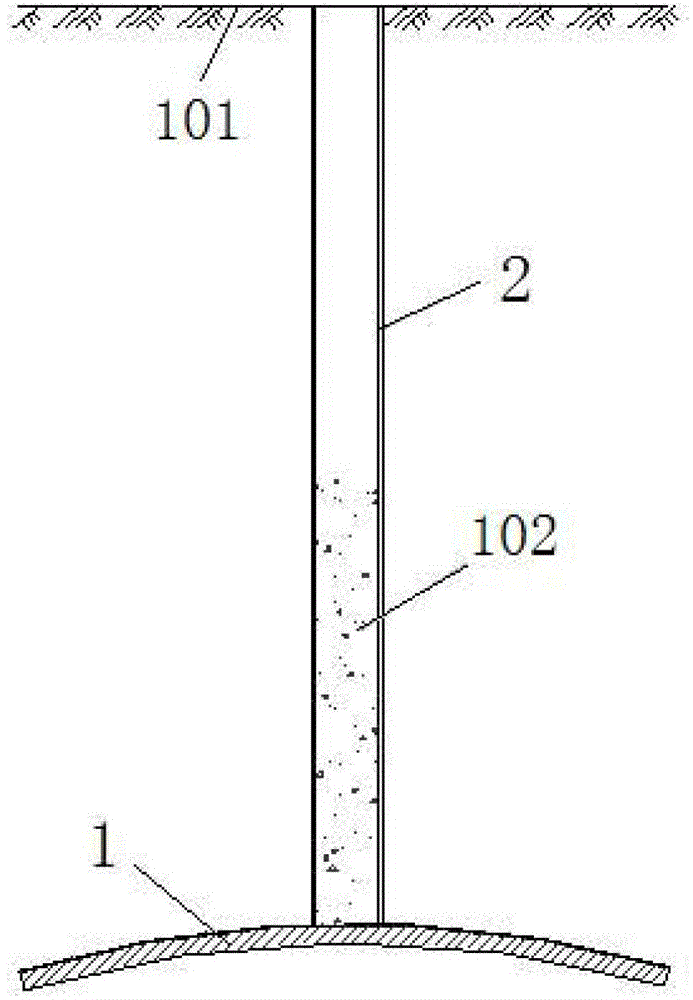

Method used

Image

Examples

Embodiment 1

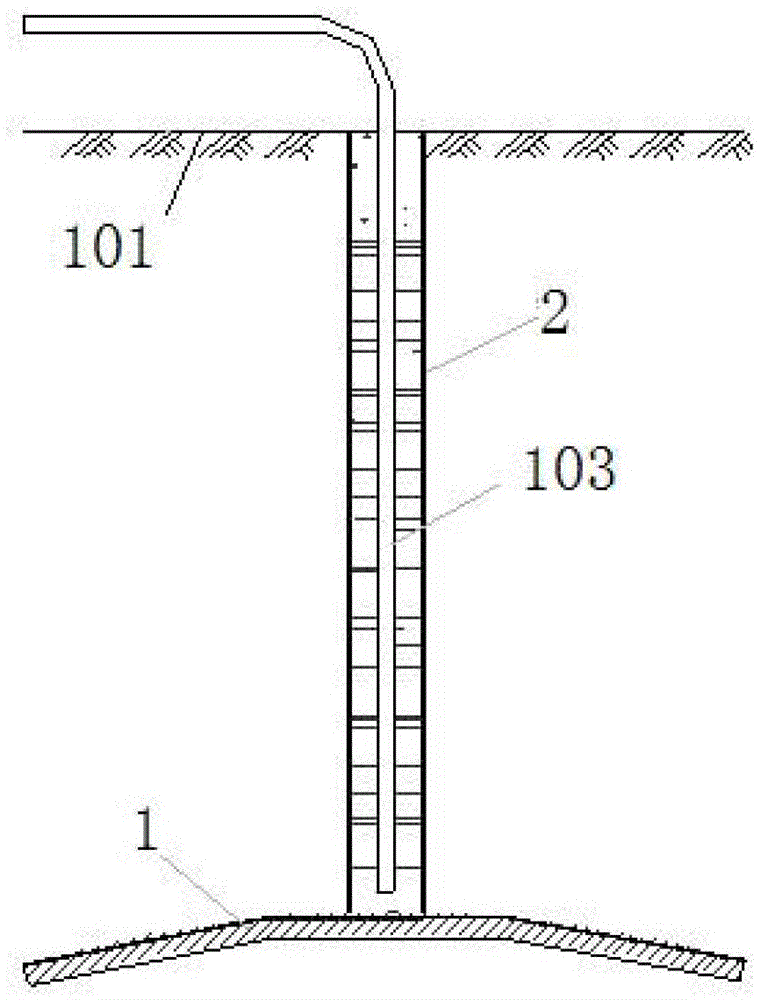

[0075] A cathodic protection system for an underground pipeline system is specifically a combination of a feeder connection device and a cathodic protection device arranged on the underground pipeline 1; the cathodic protection system for the underground pipeline system is constituted as follows: a feeder cable 401, a feeder connection Head 402, sacrificial anode 7; wherein: the lower end of the feeder cable 401 is fixedly connected to the outer wall of the underground pipeline 1 through the feeder connector 402 and forms an electrical connection, and the sacrificial anode 7 is fixedly connected to the other end of the feeder cable 401;

[0076] The waterproof casing 5 is placed in the outer protective pipe 2, and a feed connector 402 is fixedly arranged at its front end. The feed connector 402 is in close contact with the outer wall of the underground pipeline 1 and does not move, so that the feed connector 402 and the underground pipeline 12 Welding operation between the two; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com