Circumferential blowing type circular spandex spinning channel

A technology of spinning tunnel and tunnel, which is applied in the field of circular spandex spinning tunnel, can solve the problems of low spinning speed, high production cost and high solvent residue of spandex yarn, achieve rapid and effective volatilization, reduce interference and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

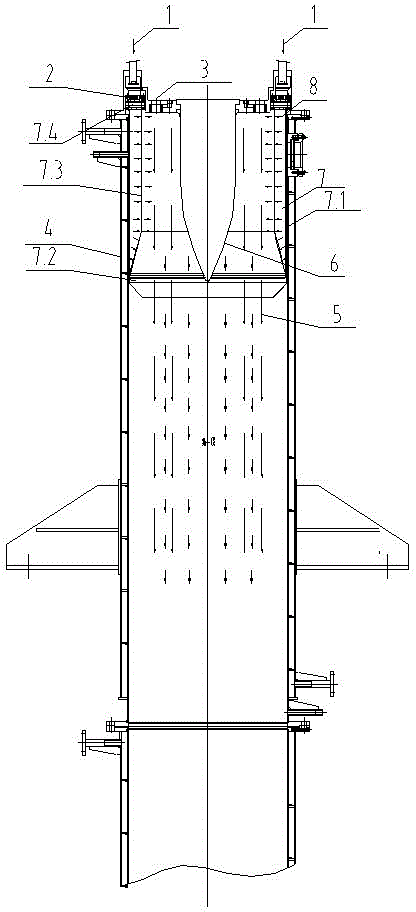

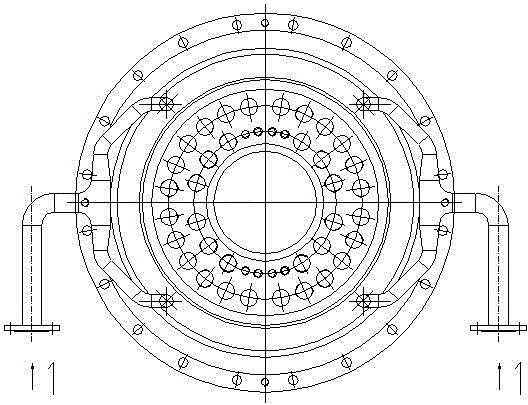

[0019] see Figure 1~2 , figure 1 It is a schematic diagram of the front structure of the circumferential blowing type circular spandex spinning tunnel of the present invention. figure 2 for figure 1 top view. Depend on figure 1 with figure 2 It can be seen that the circumferential blowing type circular spandex spinning tunnel of the present invention is mainly composed of a cylindrical tunnel body 4, a spinneret assembly 3, an annular rectifier 2, a hot air inlet 1, a static pressure chamber 7 and a diversion column 6, etc. composition. The guide column 6 is arranged in the middle of the upper part of the cylindrical tunnel body 4, the spinneret assembly 3 is arranged on the top of the cylindrical tunnel body 4, and is placed on the periphery of the guide column 6, and the hot air inlet 1 is arranged in the cylinder The top of the shaped channel body 4 is placed on the periphery of the spinneret assembly 3, the hot air inlet 1 is placed in a ring shape, the annular re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com