Color stripping liquor for dyed chinlon fabrics and color stripping method

A color stripping liquid and nylon technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as hue deviation, cylinder difference, uneven dyeing, etc., and achieve a strong and non-damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The yellow nylon fabric is stripped.

[0023] (1) Configure stripping solution:

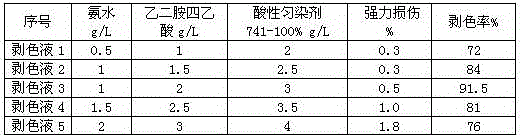

[0024] According to the formula shown in Table 1, configure the stripping solution.

[0025] Table 1, stripping solution formula table

[0026]

[0027] (2) Stripping process:

[0028] Soak the yellow nylon fabric in the stripping solution at room temperature, then raise the temperature to 95°C at a rate of 0.5°C / min, and run at this temperature for 45 minutes. Then take out the stripped fabric and wash it with 80°C hot water for 20 minutes, then cool to room temperature, wash with water and dry.

[0029] (3) Effect detection:

[0030] The K / S value was tested with a datacolor 400 spectrophotometer, and the stripping rate and the strength loss of the nylon fabric before and after stripping were detected, as shown in Table 1.

[0031] It can be seen from Table 1 that the optimal stripping solution formula is: ammonia water 1 g / L, ethylenediaminetetraacetic acid 2 g / L, ...

Embodiment 2

[0033] Embodiment 2: The black nylon fabric is stripped.

[0034] (1) Configure stripping solution:

[0035] According to the formula shown in Table 2, configure the stripping solution.

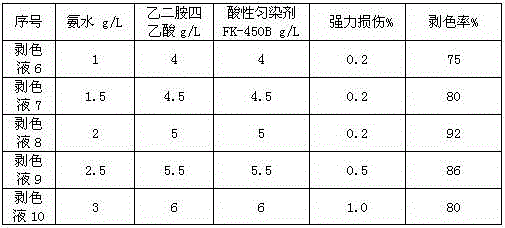

[0036] Table 2, stripping liquid formula table

[0037]

[0038] (2) Stripping process:

[0039] Immerse the black nylon fabric in the stripping solution at room temperature, raise the temperature to 100°C at a rate of 0.5°C / min, run at this temperature for 60 minutes, then take out the stripped fabric and wash it with hot water at 80°C for 20 minutes. Then cool to room temperature, wash with water, and dry.

[0040] (3) Effect detection:

[0041] The K / S value was tested with a datacolor 400 spectrophotometer, and the stripping rate and the strength loss of the nylon fabric before and after stripping were detected, as shown in Table 2.

[0042] It can be seen from Table 2 that the optimal stripping liquid formula is: ammonia water 2 g / L, EDTA 5 g / L, acid leveling agent FK-450B 5 g / L....

Embodiment 3

[0044] Embodiment 3: red nylon fabric is stripped.

[0045] (1) Configure stripping solution:

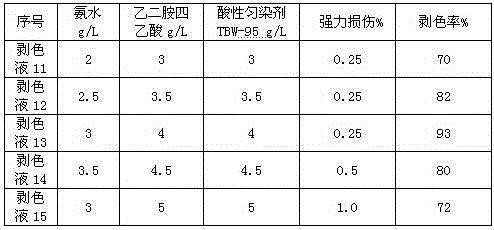

[0046] According to the formula shown in Table 3, configure the stripping solution.

[0047] Table 3, stripping liquid formula table

[0048]

[0049] (2) Stripping process:

[0050] Immerse the red nylon fabric in the stripping solution at room temperature, raise the temperature to 98°C at a rate of 1°C / min, run at this temperature for 50 minutes, then take out the stripped fabric and wash it with hot water at 95°C for 20 minutes. Cool to room temperature, wash and dry.

[0051] (3) Effect detection:

[0052] The K / S value was tested with a datacolor 400 spectrophotometer, and the stripping rate and the strength loss of the nylon fabric before and after stripping were detected, as shown in Table 3.

[0053] It can be seen from Table 3 that the optimal stripping liquid formula is: ammonia water 3 g / L, ethylenediaminetetraacetic acid 4 g / L, acid leveling agent TBW-95 4 g / L. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com