Multi-ribbed insulation wallboard

A technology of thermal insulation wall panels and thermal insulation panels, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems that thermal bridges of thermal insulation wall panels and column insulation cannot be effectively solved, serious fire prevention problems of thermal insulation wall panels, etc. Achieve the effect of saving construction time, improving thermal insulation effect, and extremely low material loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

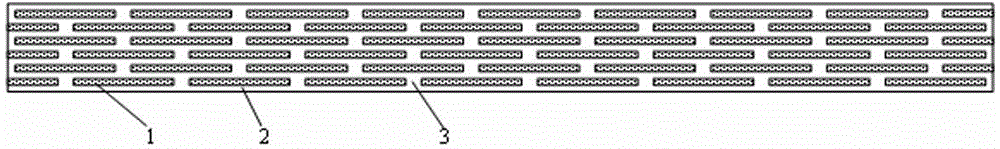

[0025] The ribbed thermal insulation wallboard includes thermal insulation board 1, concrete 2 and concrete rib 3. The thermal insulation board 1 is arranged in the concrete 2 at intervals, and the concrete rib 3 is formed between the adjacent thermal insulation boards 1 of each layer. The concrete of different layers The ribs 3 are staggered, and the concrete ribs 3 are located below the middle of the insulation board 1 of the adjacent layer. Every other layer, the insulation board 1 is to the end of one side, and the insulation board 1 of the adjacent layer is to the end of the other side. The whole ribbed thermal insulation wallboard is a rectangular board, and there are straight ports at both ends of the board.

Embodiment 2

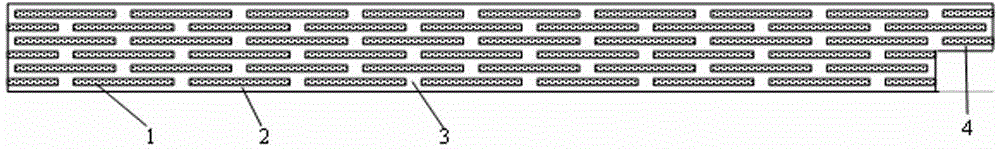

[0027] Such as figure 2 As shown, a part of one end of the ribbed thermal insulation wallboard is indented to form a stepped short joint 4, and the length of the short joint 4 is 50-100 mm. The ribbed thermal insulation wallboard forms an L-shaped board with a single short interface, and the rest are the same as in Embodiment 1.

Embodiment 3

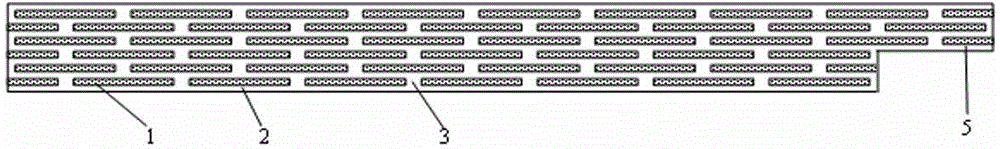

[0029] Such as image 3 As shown, a part of one end of the ribbed thermal insulation wallboard is indented to form a stepped column thermal insulation long interface 5, and the length of the column thermal insulation long interface 5 is half of the length of the column side; the dense rib thermal insulation wallboard forms a single Long interface L-shaped plate, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com