Electric blower and electric vacuum cleaner equipped with the electric blower

A vacuum cleaner and blower technology, applied in the direction of machines/engines, liquid fuel engines, pumping devices for elastic fluids, etc., can solve the problems of increased air flow loss, faster flow velocity at bending parts, and air flow turbulence, etc. Achieve the effect of increasing suction power and suppressing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] like Figure 13As shown in the perspective view of the exterior, the electric vacuum cleaner includes an electric vacuum cleaner main body 100 with a built-in electric blower and a dust collection filter, a hose 101 that is rotatably connected to the electric vacuum cleaner main body 100 at one end, and a hose 101 at the other end of the hose 101. The hose handle 102 , the extension tube 103 with one end provided at the other end of the hose handle 102 , and the suction port 104 installed at the other end of the extension tube 103 . The hose handle part 102 is provided with the switch operation part 105 for controlling the electric blower in the vacuum cleaner main body 100. As shown in FIG.

[0040] Next, use Figure 12 The vertically sectional side view of the vacuum cleaner main body 100 of the illustrated vacuum cleaner illustrates the vacuum cleaner main body 100 .

[0041] The electric vacuum cleaner main body 100 is composed of a lower casing 106 , an upper cas...

Embodiment 2

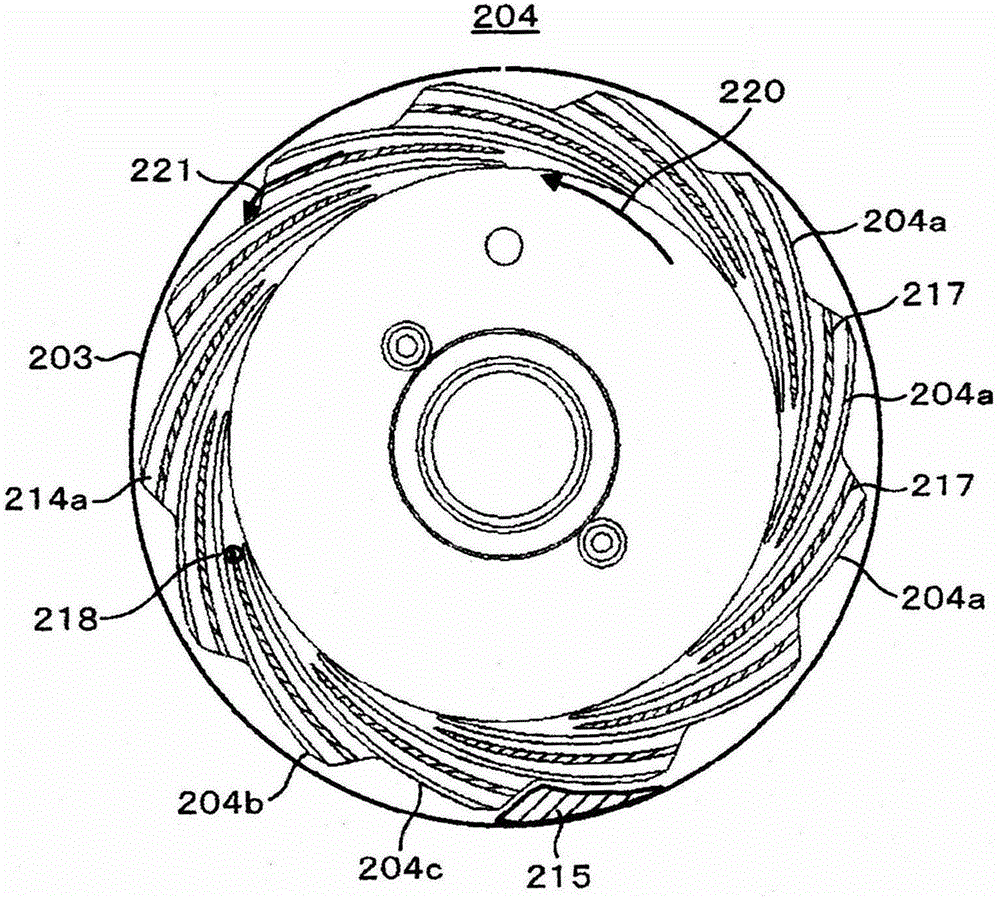

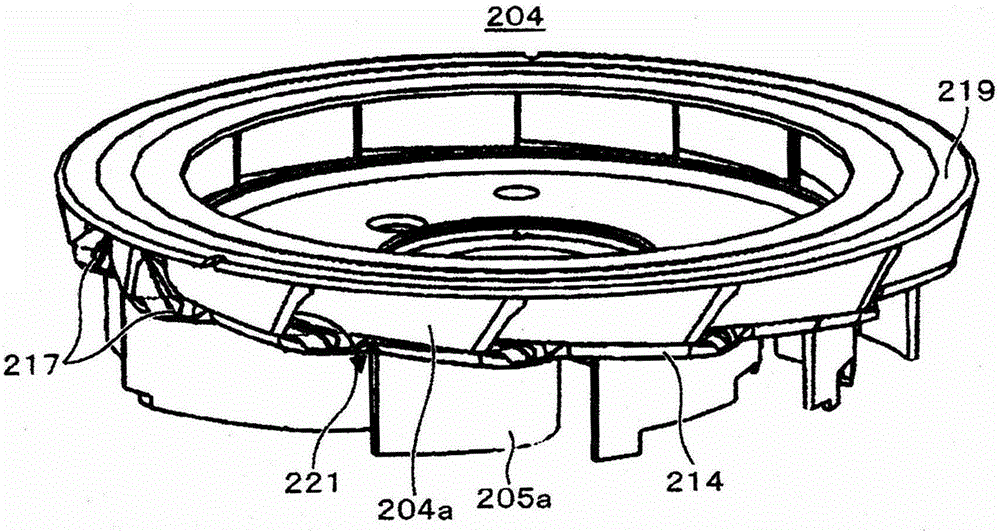

[0063] Next, use Figure 7 , Figure 8 An embodiment of the present invention will be described. Figure 7 is a top view of one embodiment of diffuser 204, Figure 8 is a perspective view of diffuser 204 . Since the basic structure is the same as that of the above-mentioned embodiments, the same symbols are used for the same elements and their descriptions are omitted.

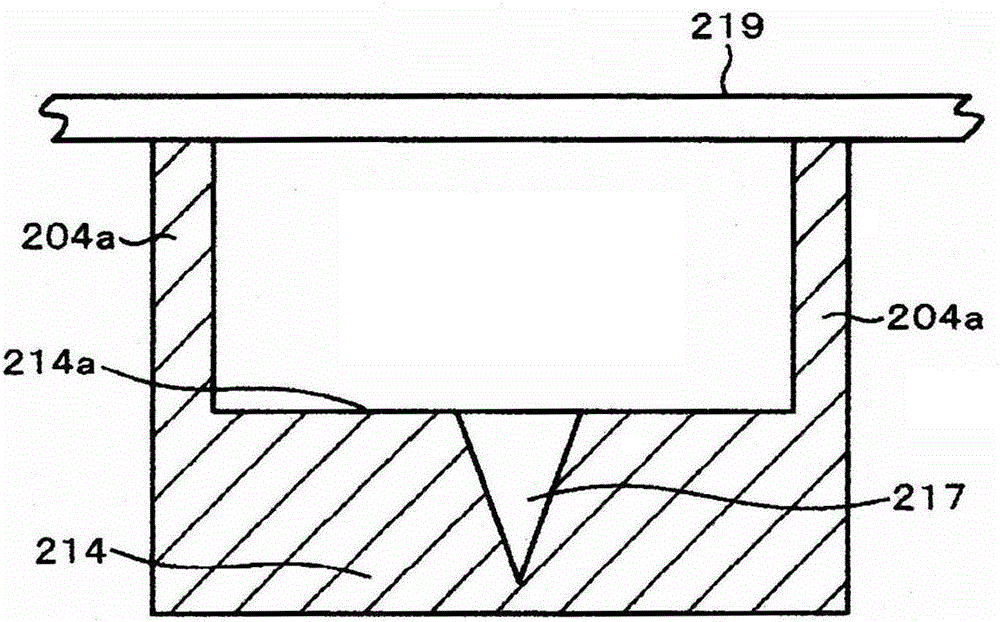

[0064] In this embodiment, there is a coincident length portion 223 adjacent to the inlet neck 218 defined by the front edge portion of the diffuser 204a and surrounded by the outlet neck 222 defined by the rear edge portion of the diffuser 204a, provided from At about 1 / 5 of the length of the overlapping length portion 223 of the diffuser 204a adjacent to the partition plate 214 on the hub surface 214a side of the diffuser of the flow path formed by the diffuser 204a and the partition plate 214 in the circumferential direction to The outer peripheral end has a concave portion having a width approximately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com