Electrohydraulic pressurizing cylinder and pressing machine equipment with same

A pressurized cylinder and electro-hydraulic technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of the maximum output force limitation, and achieve the effect of large output force, easy installation and maintenance, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

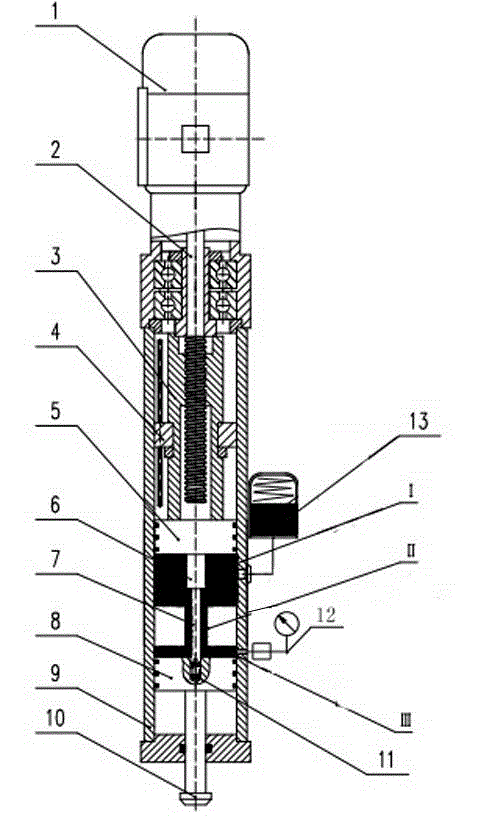

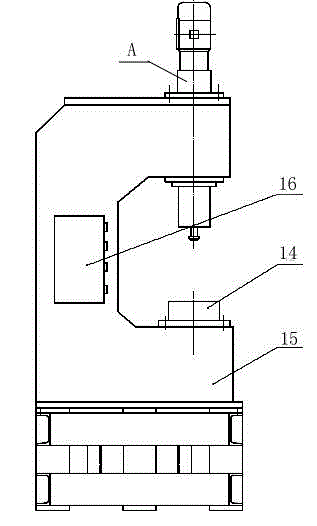

[0028] The present invention as figure 1 , 2 shown.

[0029] An electro-hydraulic pressurized cylinder, comprising a motor 1 and a cylinder body 9, the motor is installed at one end of the cylinder body 9, the front end of the motor 1 is provided with a screw 2, the screw 2 is covered with a nut 3, and the outside of the nut 3 is provided with The guide sleeve 4 is provided with an electric cylinder piston 5 at the other end of the nut 3, and the electric cylinder piston 5 is provided with a pre-press oil chamber I, a plunger oil chamber II and a pressurized oil chamber III in sequence, wherein the electric cylinder piston 5 end A plunger 6 is provided, and the plunger 6 runs through the pre-press oil chamber I, the plunger oil chamber II and the pressurized oil chamber III through the connecting rod 7; Piston 8, booster cylinder piston 8 is provided with a pressure head 10, and the pressure head 10 extends out of the cylinder body 9;

[0030] The nut 3, the guide sleeve 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com