Method for controlling direct current frequency conversion air-conditioner while operating in refrigeration mode

A DC frequency conversion, air-conditioning refrigeration technology, applied in heating and ventilation control systems, heating methods, space heating and ventilation and other directions, can solve the problems of reducing the comfort of air-conditioned rooms, frequent, low output capacity, etc., to avoid shutdown-start Frequent, avoid big horse-drawn trolleys, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

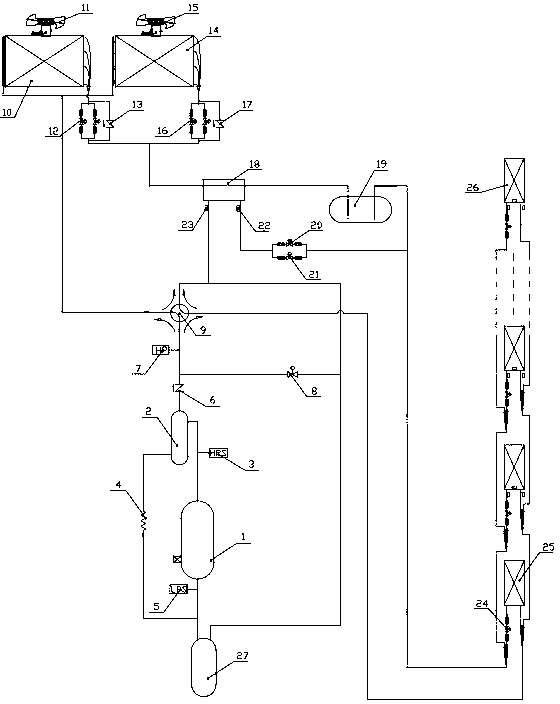

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Depend on figure 1 As shown, the DC inverter air conditioner of the present invention is driven by one outdoor unit to multiple indoor units, which includes a DC inverter compressor 1, an oil-gas separator 2, a high-pressure pressure sensor 3, an oil return capillary 4, and a low-pressure pressure sensor 5 , the first one-way valve 6, the high pressure switch 7, the unloading solenoid valve 8, the four-way reversing valve 9, the first condenser unit 10, the first outdoor fan 11, the first heating main electronic expansion valve group 12, the second One-way valve 13, second condenser unit 14, second outdoor fan 15, second heating main electronic expansion valve group 16, third one-way valve 17, heat exchanger 18, high-pressure liquid receiver 19, first section Flow electronic expansion valve 20, second throttle electronic expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com