Fusing method of temperature compensation of humidity sensor

A humidity sensor and temperature compensation technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to achieve full compensation, application limitations, and low fitting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

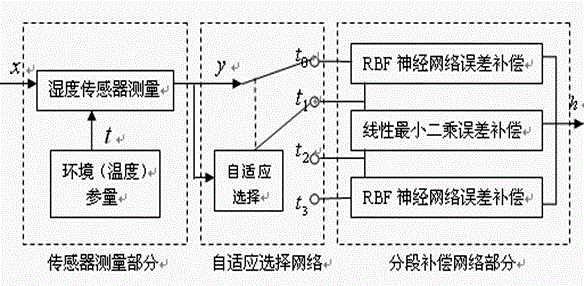

[0020] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

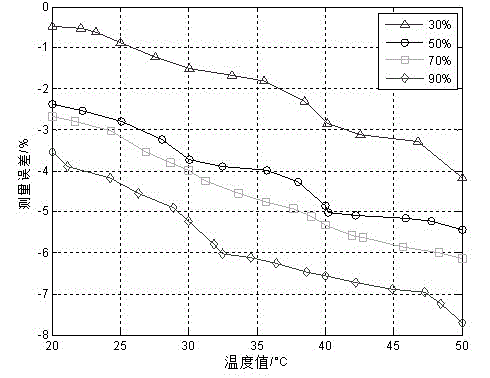

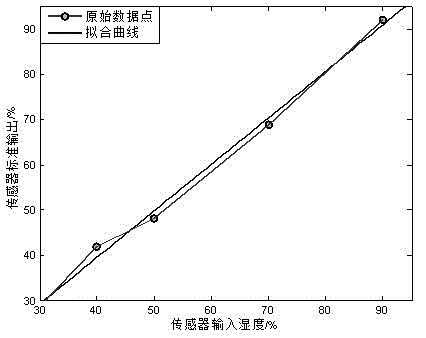

[0021] The fusion method of the temperature compensation of the humidity sensor, assuming that the characteristic function of the humidity sensor is y=f(x), x∈[δ 0 ,δ h ], where y is the output of the sensor, x is the input of the sensor, and the input signal range is δ h -δ 0 , which is characterized in that the temperature parameter t is added, according to the characteristics of the characteristic curve of the humidity sensor under the influence of temperature, which is linear in the middle and non-linear at both ends, so that t0<t1<t2<t3, the formula (1) is obtained,

[0022] y = f ( x , t ) = f 1 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com