Distributed control system

A distributed control and control interface technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of being unable to intuitively understand operating variables, prone to misoperation, and affecting the convenience and accuracy of APC operations, etc. problem, to achieve the effect of APC control convenience and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the following examples are given to further describe the embodiments of the present invention in detail.

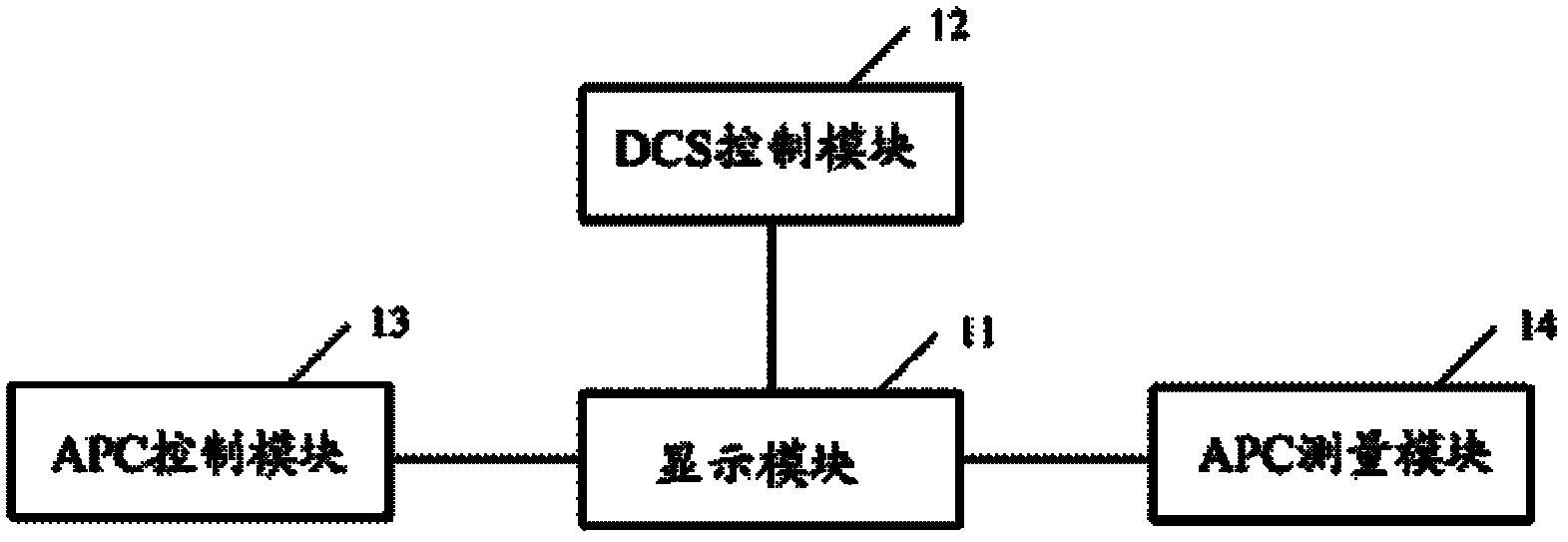

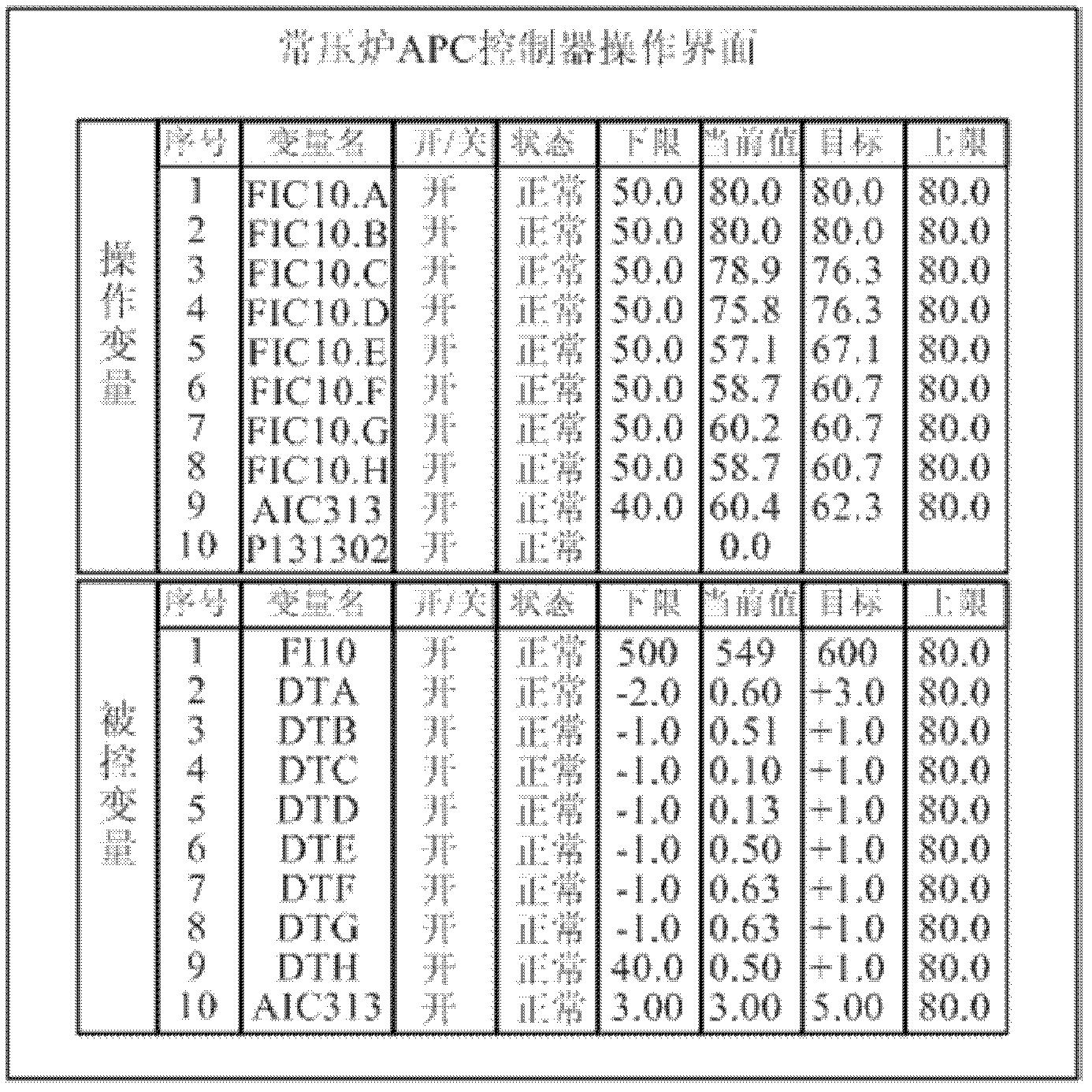

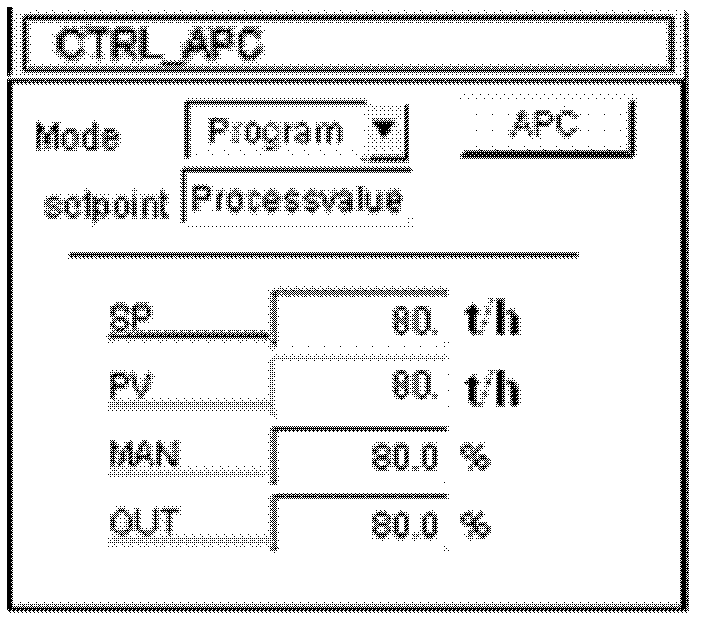

[0030] The embodiment of the present invention provides a distributed control system including a display module, a DCS control module, an APC control module and an APC measurement module. Among them, the display module is used to display the DCS operation interface, and provide the APC control interface and the APC measurement interface through the DCS operation interface; the DCS control module is used to receive the user's DCS operation instruction through the DCS operation interface, and execute the corresponding DCS operation instruction. DCS operation; the APC control module is used to display the information of the APC manipulated variable through the APC control interface when the user selects the APC control interface, receive the user’s mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com