Self-cooling power cable

A power cable, self-cooling technology, applied in power cables, cables, circuits, etc., can solve the problems of self-measurement and self-cooling, cable aging, fire, etc., and achieve good practicability and economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further clarified below in conjunction with the accompanying drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and not to limit the scope of the present invention.

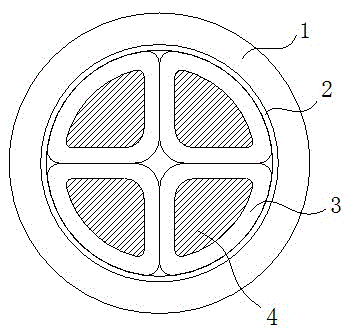

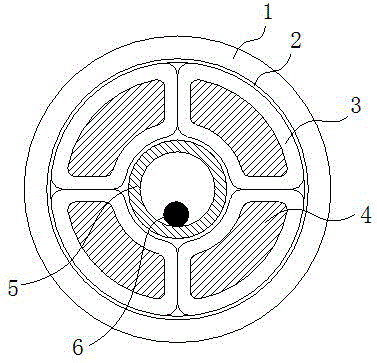

[0014] Such as figure 2 As shown, the self-cooling power cable includes 1 to 5 cable cores arranged in the outer sheath 1 and wrapped by wrapping tape (conventional power cable) or steel tape armor (steel tape armored power cable) 2, flexible Metal pipe 5 and temperature measuring line 6; each cable core is composed of conductor 4 wrapped by insulating layer 3, and the shape of conductor 4 is circular, fan-shaped or semicircular. Each cable core is arranged around a flexible metal tube 5 , and a temperature measuring line 6 is arranged inside the flexible metal tube 5 . The flexible metal pipe 5 is a sealed flexible meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com