Ditching Fertilizer

A fertilizer applicator and frame technology, which is applied in fertilization devices, excavation/covering ditches, fertilizer distributors, etc., can solve the problems of low efficiency of manual digging and fertilization, poor adaptability of mechanical ditching and fertilization, and inability of ditching depth. Adjustment and other issues to achieve the effect of easy access, convenient operation, and reasonable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

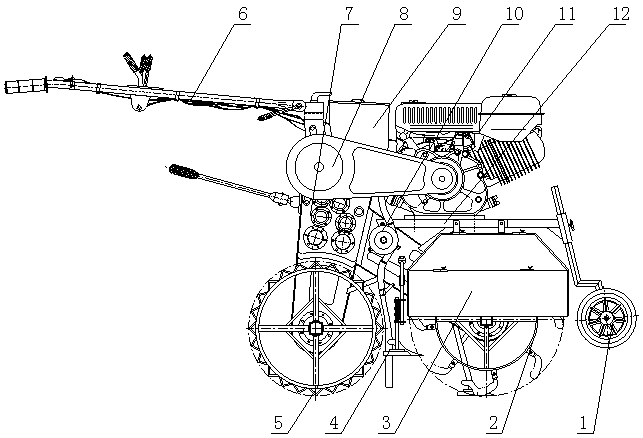

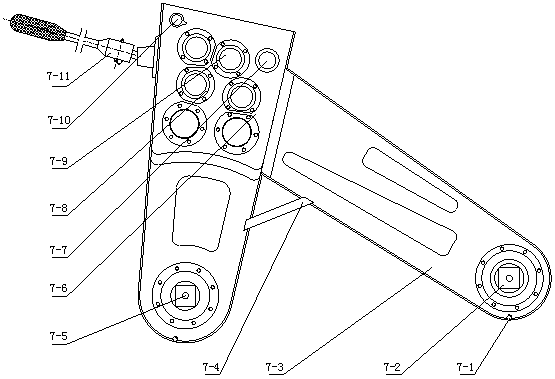

[0031] see figure 1 , ditching and fertilizing machine, including frame 12, engine 11, ditching mechanism 2, fertilization mechanism 10, soil covering mechanism 4, walking wheel 5; engine 11 is arranged on the frame 12, and is respectively connected to ditching mechanism 2 through gearbox 7 and road wheels 5; ditching mechanism 2 and road wheels 5 are arranged on the bottom of frame 12 one after the other, near the rear of ditching mechanism 2, fertilization mechanism 10 is provided, and both sides of fertilization mechanism 10 are provided with soil covering mechanism 4 .

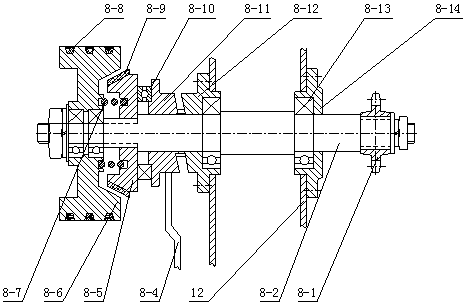

[0032] see in conjunction figure 1 and figure 2 , between the output shaft of engine 11 and the power input shaft 7-9 of gearbox 7, a main clutch 8 is used to cut off and combine the power of the engine, belt pulley 8-6, separation spring 8-7, friction plate 8-9, Thrust bearing 8-10 and separation sleeve 8-11 are set on the clutch shaft 8-2 to form the main clutch, and the clutch shaft 8-2 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com