Large-scale huller

A hulling machine, a large-scale technology, applied in the direction of grain hulling, hulling, grain degermination, etc., to achieve the effect of reduced loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

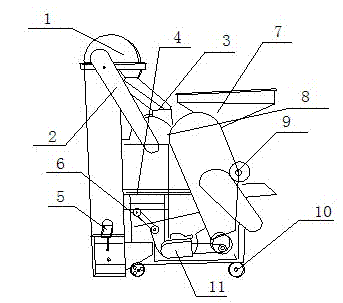

[0011] Such as figure 1 Shown, a kind of large shelling machine comprises pumping system 1, feeding port 7, material conveying equipment, support 4 and motor, and described pumping system 1 is arranged on the top of support 4, and described feeding port 7 is set On the upper side of the middle part of the bracket 4 , the motor 9 is arranged in the middle part of the bracket 4 , the pumping system 1 is connected with the conveying equipment, and the motor 9 is connected with the feeding port 7 .

[0012] The pumping system 1 is also connected with a transmission system 2 . The pumping system 1 is also connected with a material conveying channel 3 , and the material conveying channel 3 is connected with a storage bin 8 . The left side of the bottom of the support 4 is provided with a discharge port 5, the transmission system 6 is located in the middle of the support 4, the transmission equipment 11 is located at the bottom of the transmission system 6, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com