Crushing roller of roller type high-frequency vibration crusher and manufacturing method thereof

A technology of high-frequency vibration and manufacturing method, applied in grain processing and other directions, can solve problems such as low efficiency, easy slippage and wear, uneven crushing particle size, etc., and achieve the effect of reducing use cost, lightening load, and reducing mechanical operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

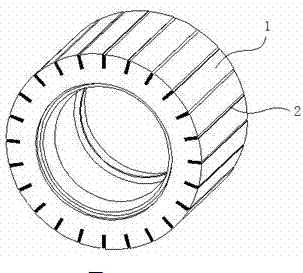

[0025] Such as figure 1 As shown, the crushing roller of the present invention includes a roller base 1, on which a metal body 2 having a hardness different from that of the roller base 1 is arranged, and the metal body 2 on the roller base 1 is formed on the roller base 1 Slotted inlays evenly spaced around the circumference (see figure 1 ) or inserts (not shown) or columnar inserts (see Figure 4 , Figure 5 ).

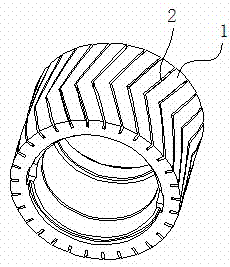

[0026] The inlaid metal body 2 can also be distributed on the roller base 1 in a V shape, such as figure 2 As shown, or the inlaid metal body 2 is distributed on the roller base 1 in a zigzag shape, such as image 3 shown.

[0027] The roller base is made of high-hardness, high-wear-resisting alloy obtained by casting and heat-treating one of high-chromium alloy, high-manganese alloy, high-tungsten alloy, high-vanadium alloy, multi-element alloy steel, high-carbon steel, and white cast iron. The metal body adopts one of medium and low carbon steel, low alloy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com