Heavy reduction technology for improving center segregation and center porosity of super-thick slabs

A technology of loose center and extra-thick slab, which is applied in the field of continuous casting slab reduction, can solve the problems of reduced welding performance, shortened service life, and difficult welding of steel plates, etc., and achieves the goal of controlling loose center and improving the quality of extra-thick slab Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

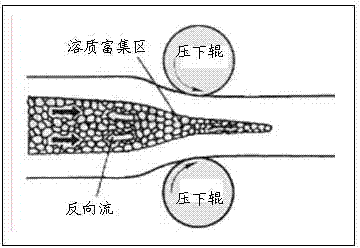

Method used

Image

Examples

Embodiment 1

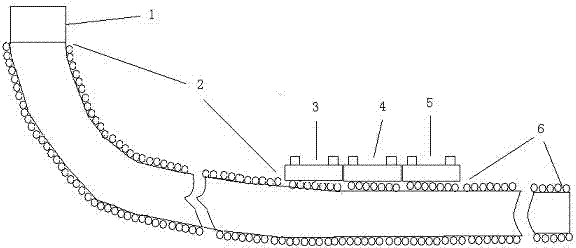

[0020] Example 1: The steel grade is Q345D, the slab thickness is 300mm, the width is 2270mm, the detected superheat is 35℃, the pulling speed is 1.0m / min, and the specific water volume in the secondary cooling zone is 0.4L / kg. The 9th sector 3 and the reduction amount are 5.0mm, the 10th sector 4 and the 11th sector 5 are both 3mm, and the 9th sector 3 cylinder pressure is 1800KN.

[0021] Implementation effect: After the low magnification inspection of the slab, the central segregation is C1.0, the central porosity is C1.0, and no intermediate cracks appear. see low magnification photos image 3 .

Embodiment 2

[0022] Example 2: The steel grade is Q345R, the slab thickness is 360mm, the width is 2070mm, the detection superheat is 25℃, the pulling speed is 0.8m / min, and the specific water volume in the secondary cooling zone is 0.5L / kg. The 11th sector 5, the reduction amount is 9mm, the 9th sector and the 10th sector are both 2.5mm, and the 11th sector cylinder pressure is 2000KN.

[0023] Implementation effect: After the low magnification inspection of the casting billet, the central segregation is C0.5, the central porosity is C0.5, and no intermediate cracks appear. see low magnification photos Figure 4 .

Embodiment 3

[0024] Example 3: Steel grade EH36, billet thickness 420mm, width 2070mm, detection superheat 10℃, pulling speed 0.6m / min, specific water volume in secondary cooling zone 0.6L / kg. The 10th sector 5 and the reduction amount are 12mm, the 9th sector 3 and the 10th sector 4 are both 2mm, and the 11th sector 5 pressure is 2500KN.

[0025] Implementation effect: After the low magnification inspection of the casting billet, the central segregation is C0.5, the central porosity is C0.5, and no intermediate cracks appear. see low magnification photos Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com