Welding device and welding equipment with same

A welding device and welding equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heat loss, low energy utilization rate, poor working environment, etc., and achieve the effect of effective welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

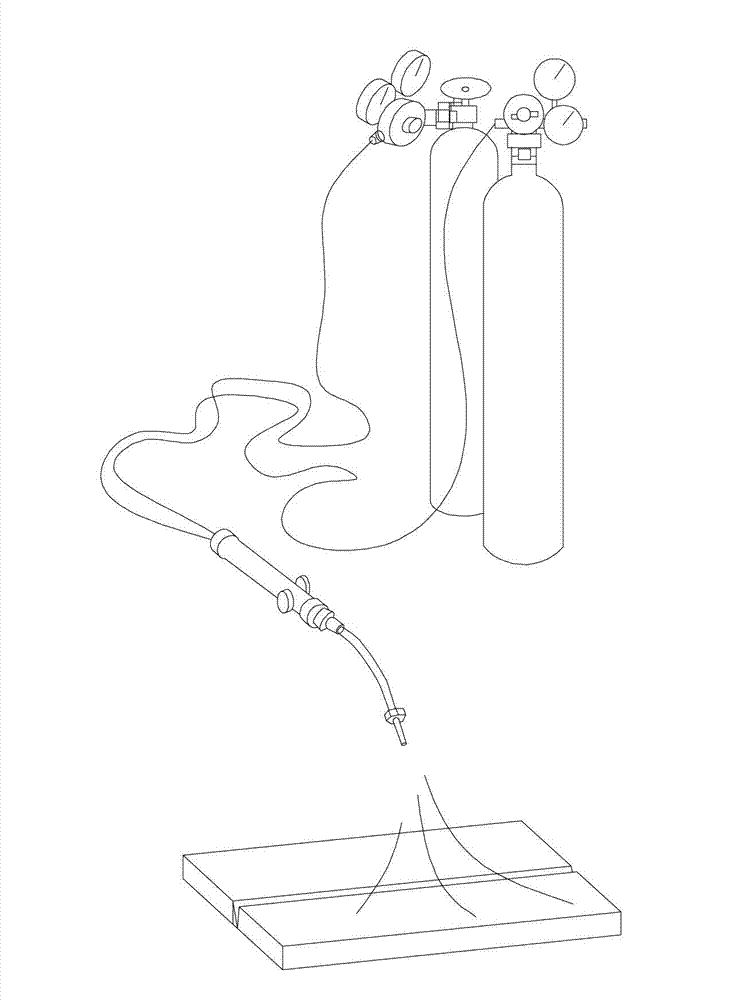

[0042] The core of the present invention is to provide a welding device with pre-welding heating function, eliminating the waiting time between preheating and welding, and heating the welding interface of the workpiece and the workpiece near the interface through the induction heater; at the same time, the application The welding equipment of the welding device can automatically realize the preheating welding operation. The detailed description will be given below in conjunction with the drawings of the specification.

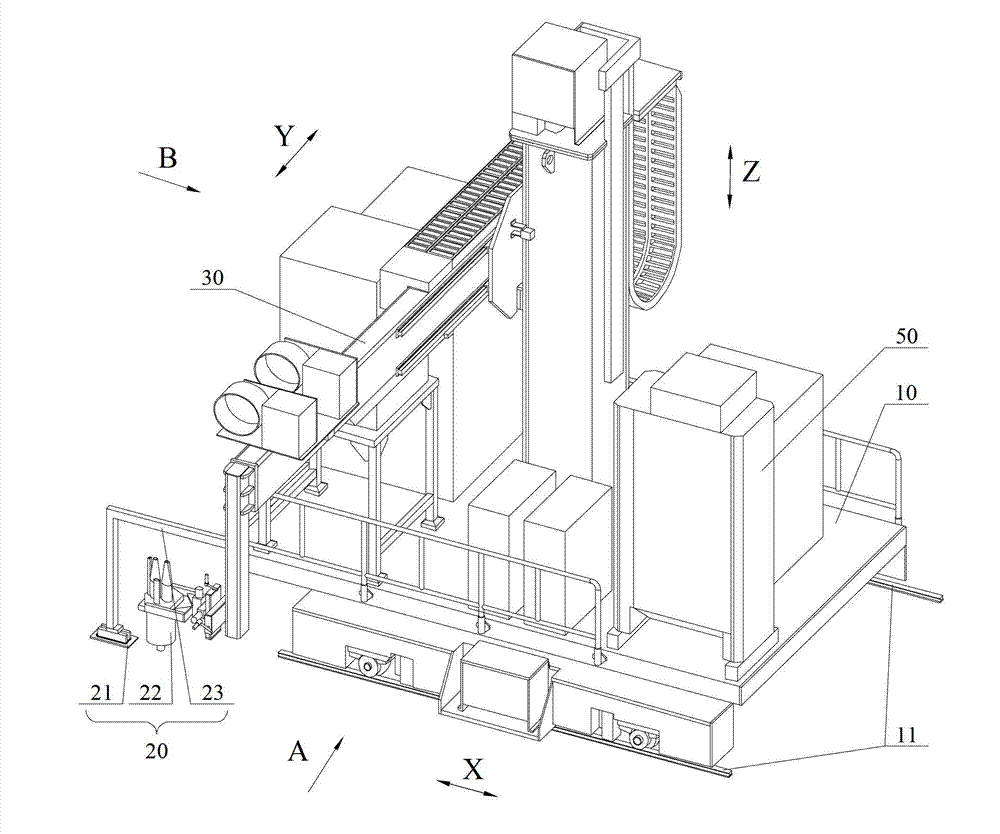

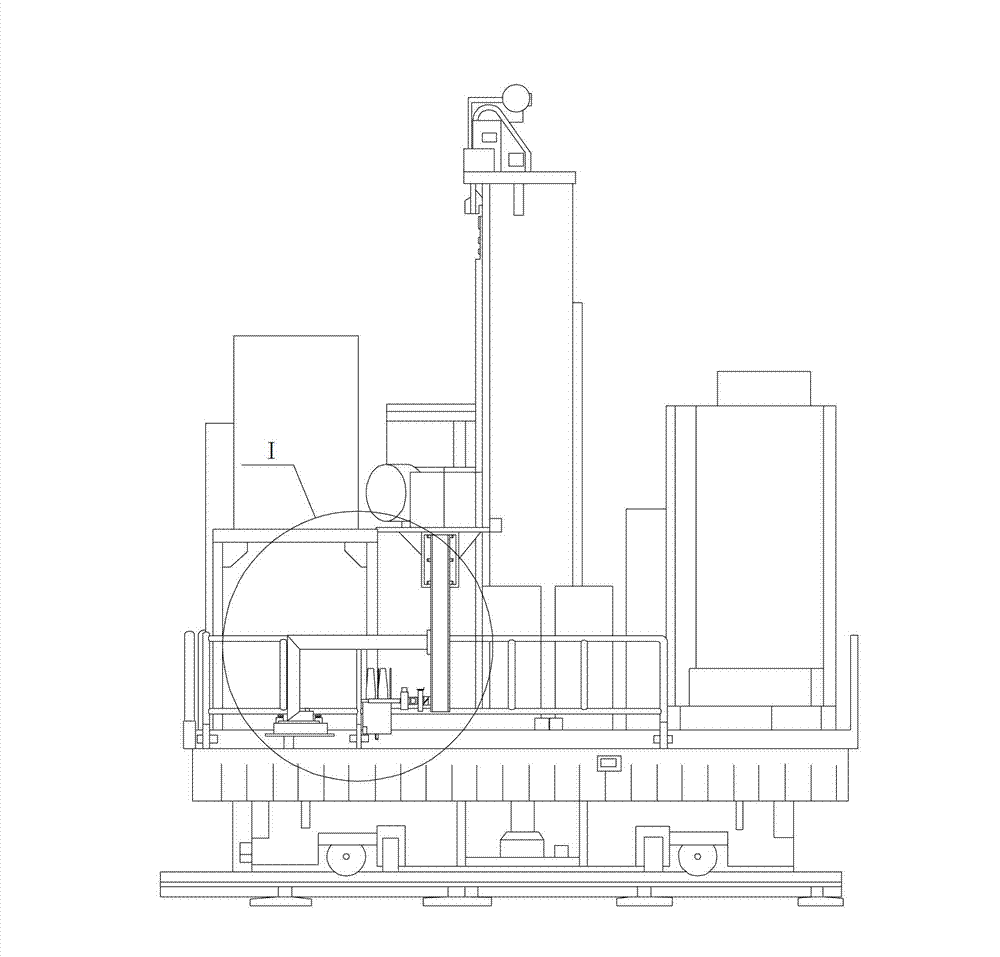

[0043] See figure 2 , image 3 with Figure 4 ,among them, figure 2 Is an axonometric diagram of the welding equipment in this embodiment, image 3 Yes figure 2 A view of Figure 4 Yes figure 2 B to view.

[0044] As shown in the figure, the welding equipment includes a driving trolley 10 that can be displaced in a first direction X. The first direction X is the welding seam forming direction. The driving trolley 10 is displaced along the first direction X at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com