Plastic outer knurling machine of high-frequency induction heating type steel tube for handrail

A technology of high-frequency induction heating and plastic outer layer, which is applied in the field of plastic outer layer knurling, can solve the problems of energy consumption, low production efficiency, and high production cost, and achieve the effects of increased production efficiency, reduced energy consumption, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

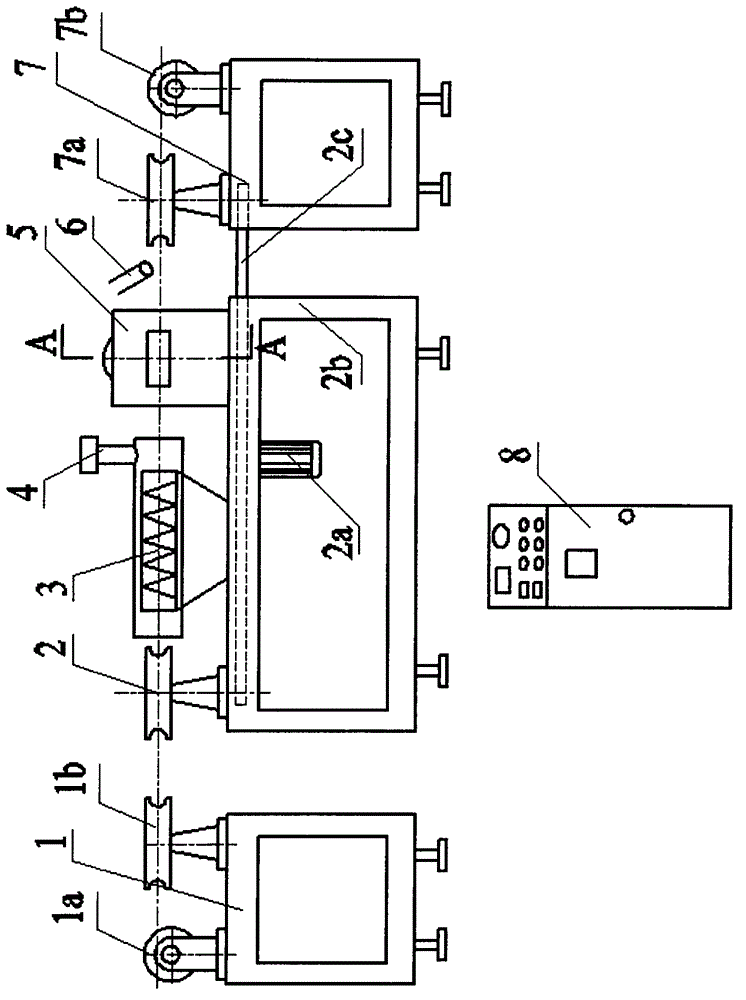

[0026] Below is working principle and working process of the present invention:

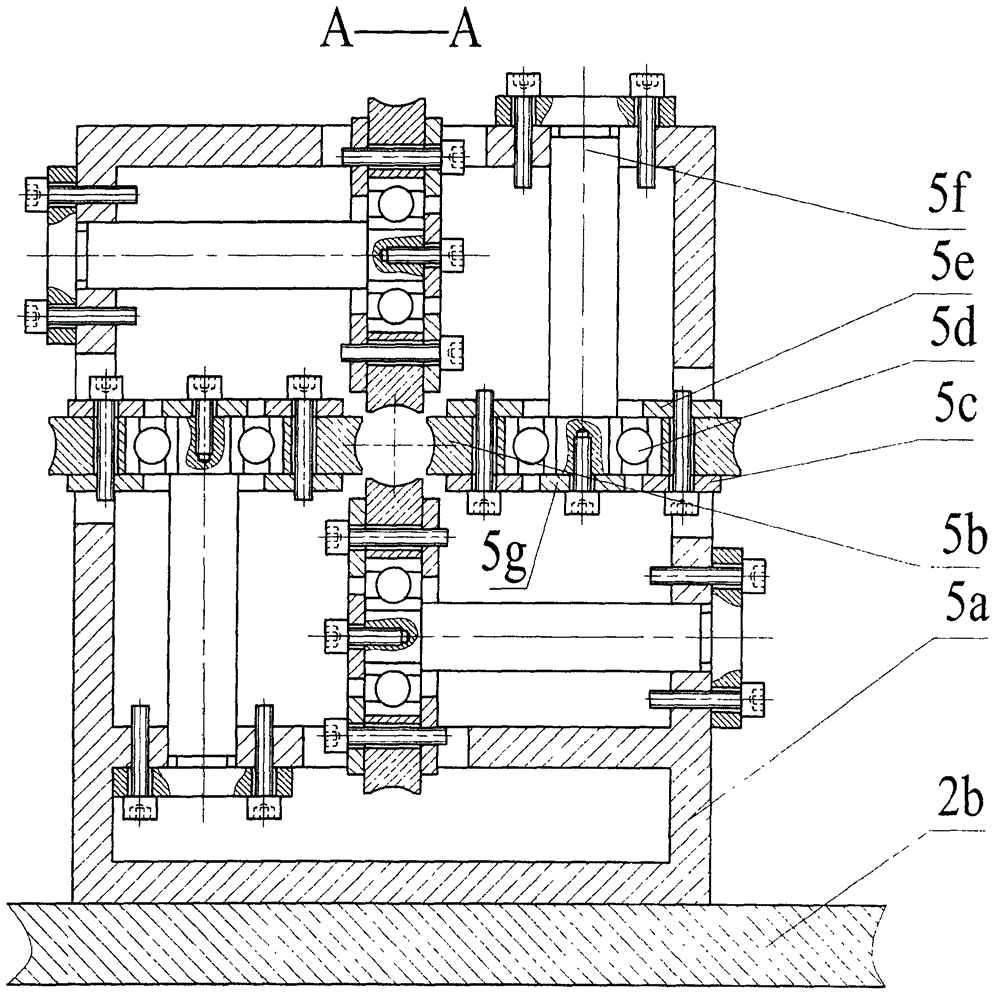

[0027] as attached figure 1 As shown, the plastic-coated steel pipes of different types and cross-sectional shapes must be customized for the horizontal axis roller 1a and vertical axis roller 1b of the pipe inlet station 1, the feeding roller 2b of the pinch device 2, and four of the plastic outer layer knurling device 5. Knurling wheel 5b, vertical axis driving roller 7a and horizontal axis roller 7b of pipe outlet station 7; in the present invention, the size of the induction coil of the high-frequency induction preheating device 3 is related to the section size of the plastic-coated steel pipe.

[0028] The plastic-coated steel pipe passes through the horizontal axis roller 1a and vertical axis roller 1b of the pipe inlet station 1, and is manually pushed into the feeding roller 2 of the feeding device 2, driven by the frequency conversion speed regulating motor 2a and the synchronous toothed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com