Electromagnetic type magnetic rail brake

A magnetic rail brake, electromagnetic technology, applied in the direction of brakes, electromagnets, and railway braking systems where the braking element interacts with the track, etc., it can solve the problems of easy damage to the excitation coil, limited braking force of the magnetic rail brake, and terminal The internal cleaning protection device is not included in the working magnetic circuit, etc., so as to achieve the effect of reasonable magnetic circuit structure design, saving longitudinal space, and preventing damage to the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

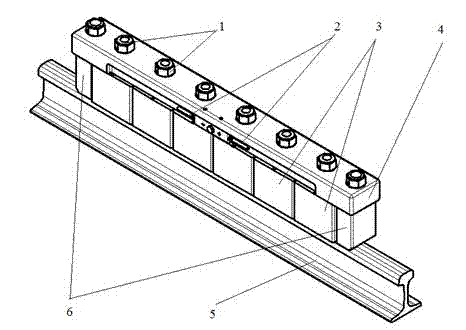

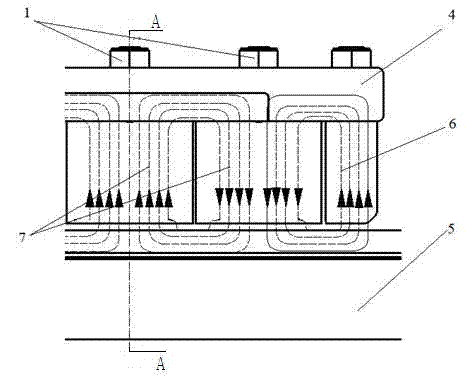

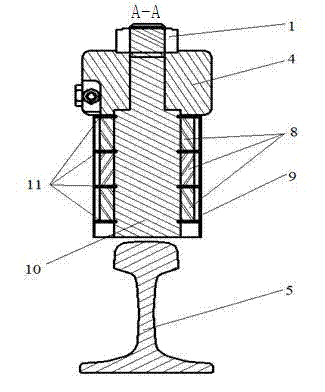

[0015] Such as Figure 1-2 As shown, the electromagnetic rail brake of the present invention is installed in pairs between the two wheels of the bogie on both sides of the rail vehicle, and an electromagnetic rail brake includes a longitudinal beam 4, and the longitudinal beam 4 is other parts and electromagnetic The basic component for connecting or installing the magnetic track brake; the longitudinal beam 4 is located on the upper part of the track 5, parallel to the track 5 and arranged along the longitudinal direction of the track, and is arranged in the longitudinal space between the track 5 and the longitudinal beam 4 m 3 electromagnets, m ≥2, the same below. This m A plurality of electromagnets 3 are distributed at equal intervals along the longitudinal direction of the track 5, each electromagnet 3 is directly above the track 5, and the axial direction of each electromagnet 3 is all vertically perpendicular to the track 5 and the longitudinal beam 4 at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com