Packaged object filling device and method

A filling device and packaging technology, which is applied in the types of packaging items, special packaging items, packaging, etc., can solve the problems of inability to cope with filling volume, deterioration of filling accuracy, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

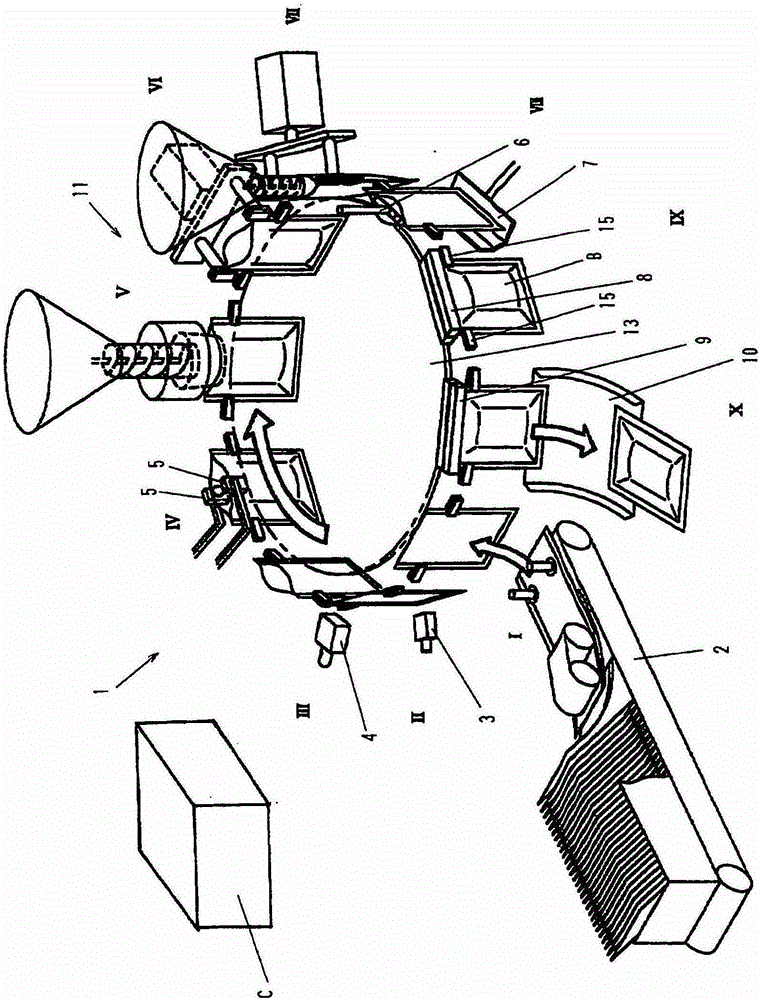

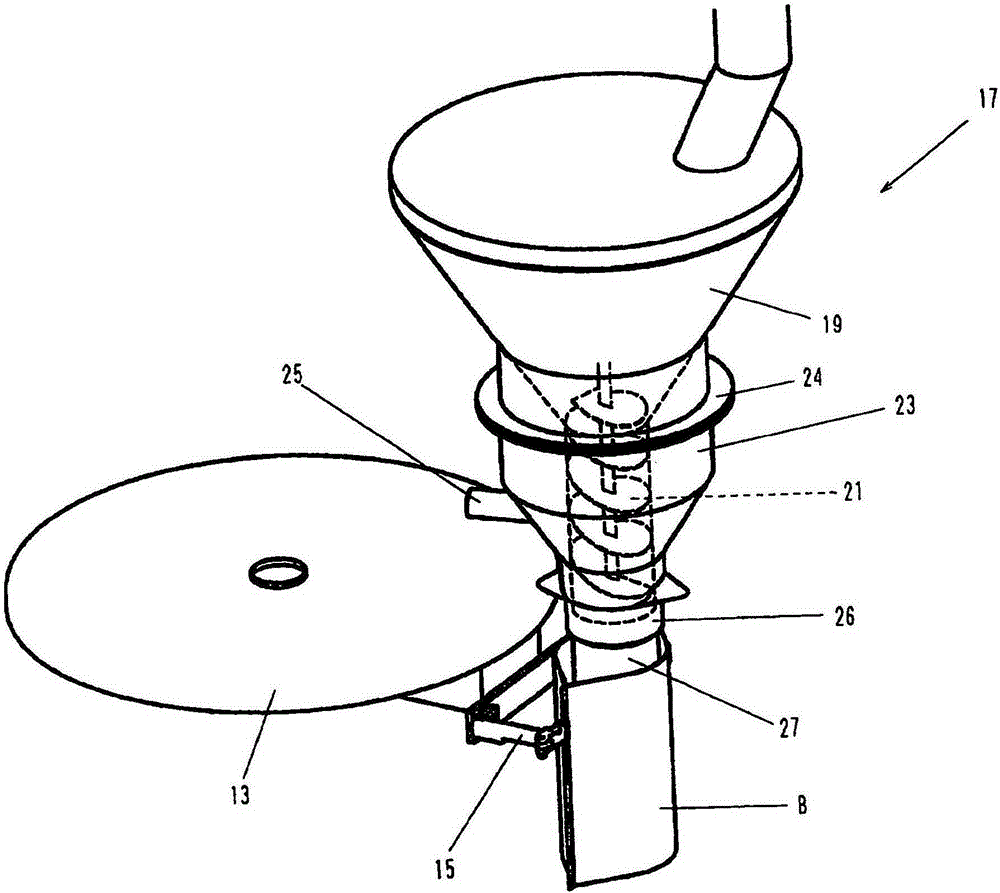

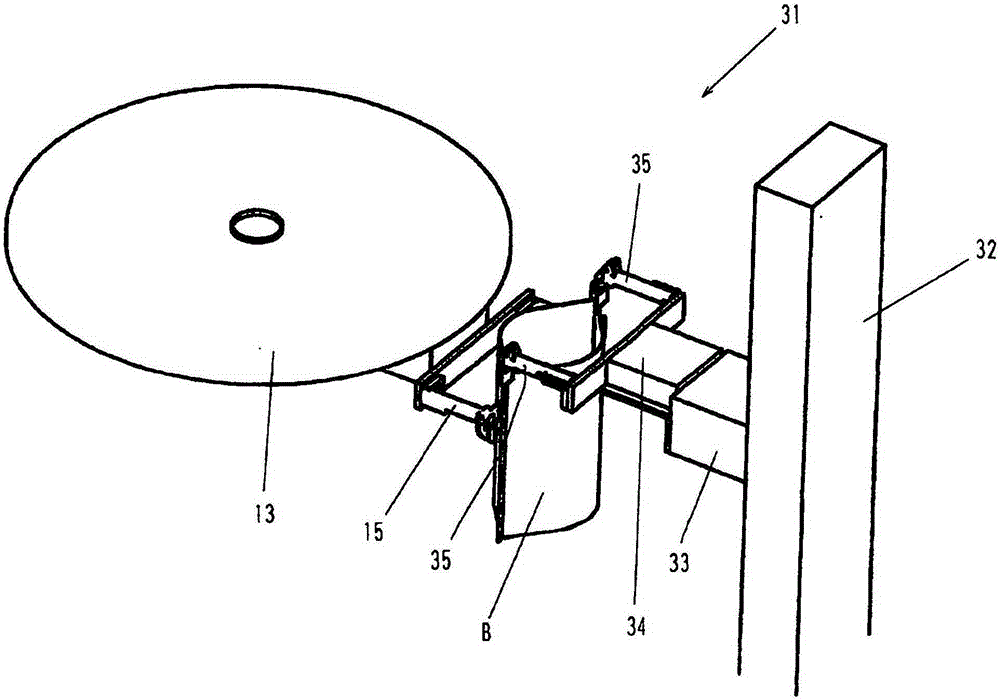

[0073] Next, a packaged object filling device (hereinafter referred to as "filling device") according to an embodiment of the present invention will be described with reference to the drawings.

[0074] figure 1 It is a schematic perspective view showing the overall configuration of an intermittent transfer type vertical pouch packaging machine (hereinafter referred to as "packaging machine") 1 using a filling device 11 according to an embodiment of the present invention. In addition, as will be described later, two embodiments have been described in this application, and although the control methods are different, the configuration of the filling device 11 is the same in either case. Symbol 13 is a rotary table that rotates in the direction of the arrow in the figure, connected with an unillustrated indexing unit and a motor, determined by the indexing unit, so that the rotary table repeatedly moves and stops intermittently corresponding to the rotation angle of the motor . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com