Non-compressed transformation dry powder pump

A dry powder pump, non-compression technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problem of high failure frequency of variable pressure chambers, and achieve the effect of simple structure, low engineering cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings.

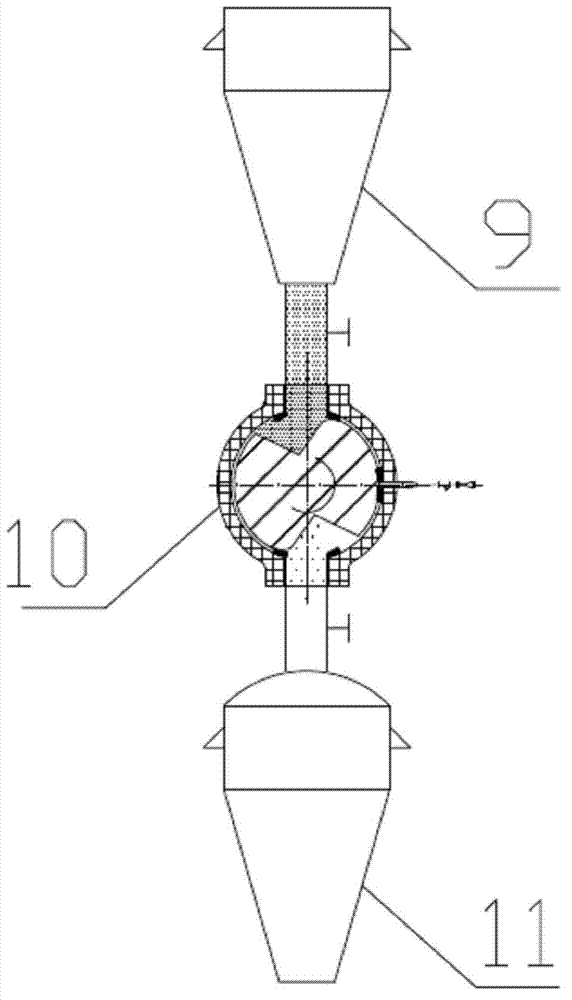

[0023] figure 1 It is a dry powder pressure-changing conveying system with this device. The powder enters the powder conveying system from the top of the normal-pressure silo 9, and is conveyed to the high-pressure silo 11 through the device 10 through variable pressure.

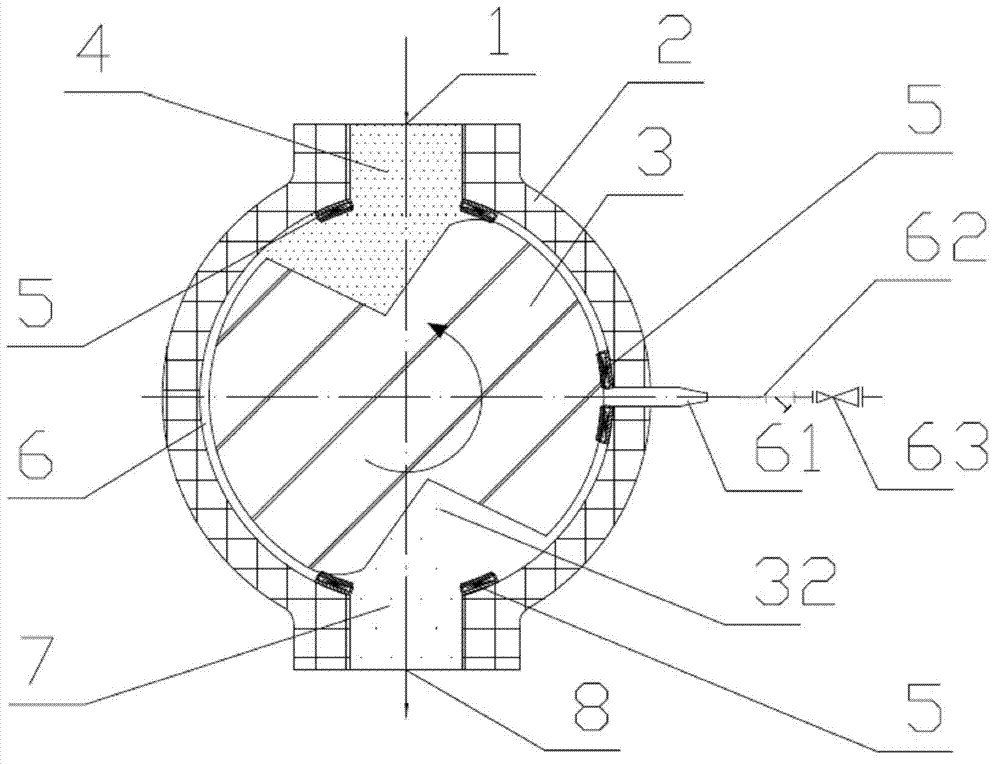

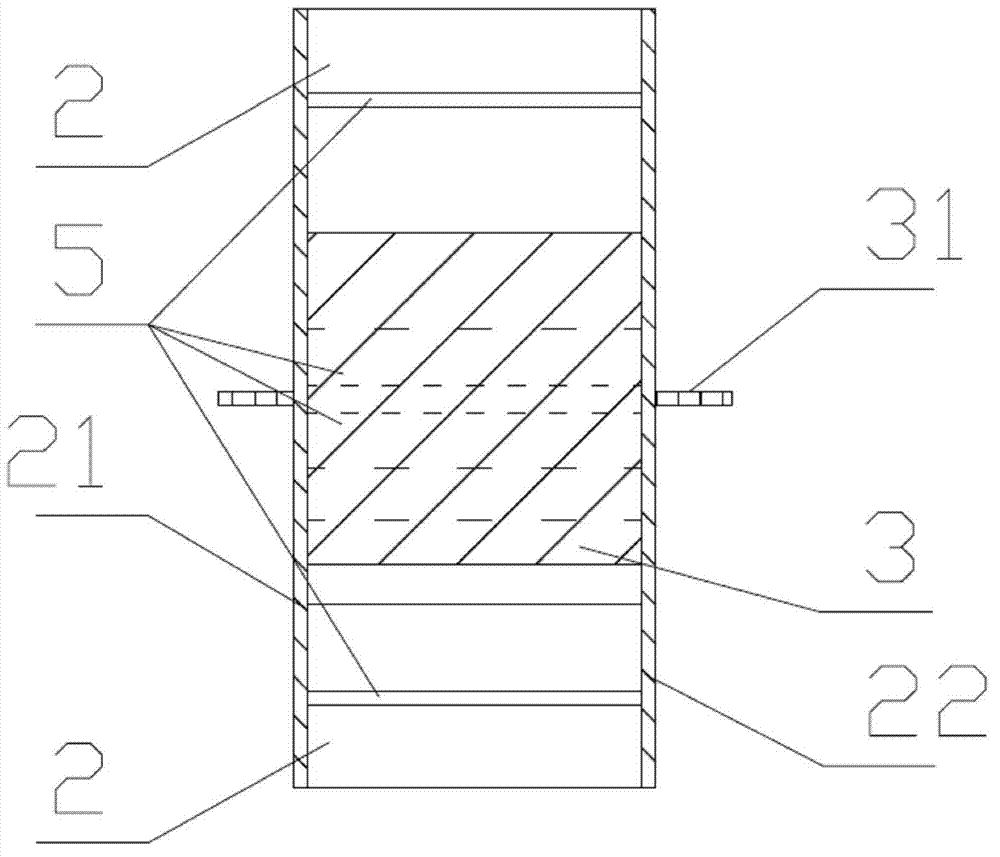

[0024] figure 2 It is the front sectional structure diagram of the variable pressure dry powder pump of the present invention. The pump body 2 is provided with a powder inlet 1, a powder suction chamber 4, a sealing table 5, a rotor chamber 6, an exhaust pipe 61, a filter 62, and a pressure reducing valve. 63, powder pressing chamber 7 and powder discharge outlet 8. Rotor chamber 6 is provided with rotor 3, and rotor 3 is connected with rotating shaft 31, and rotating shaft 31 is connected on pump body front end cover 21 and rear end cover 22, and rotating shaft 31 provides pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com