Concrete hollow slab bridge strengthened by transverse integral clamping connection

A hollow slab bridge and concrete technology, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., can solve the problems of increased lateral distribution coefficient of veneer load, disadvantageous, disadvantageous quality, etc. Avoid the effect of stress on the veneer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

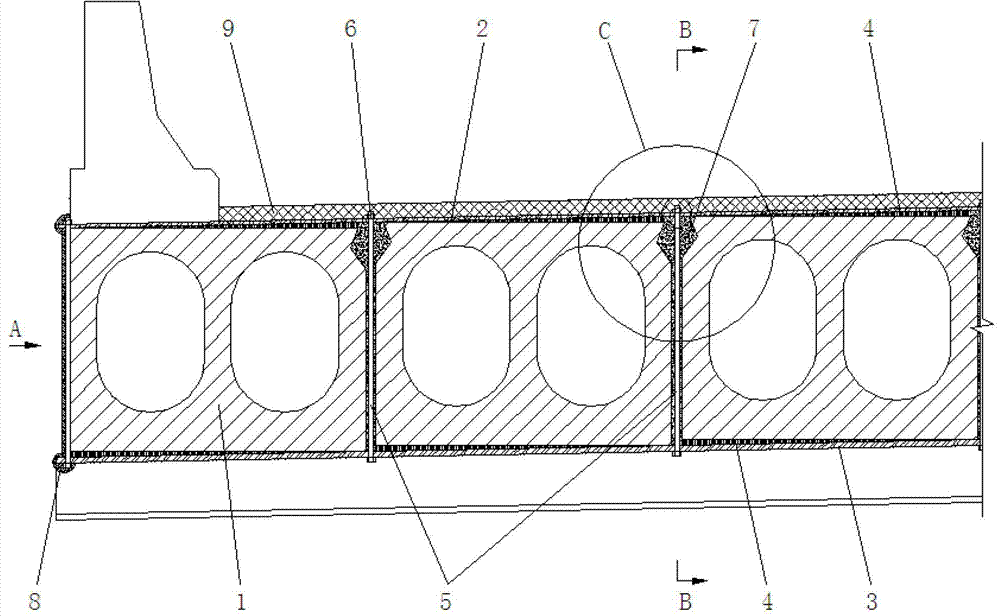

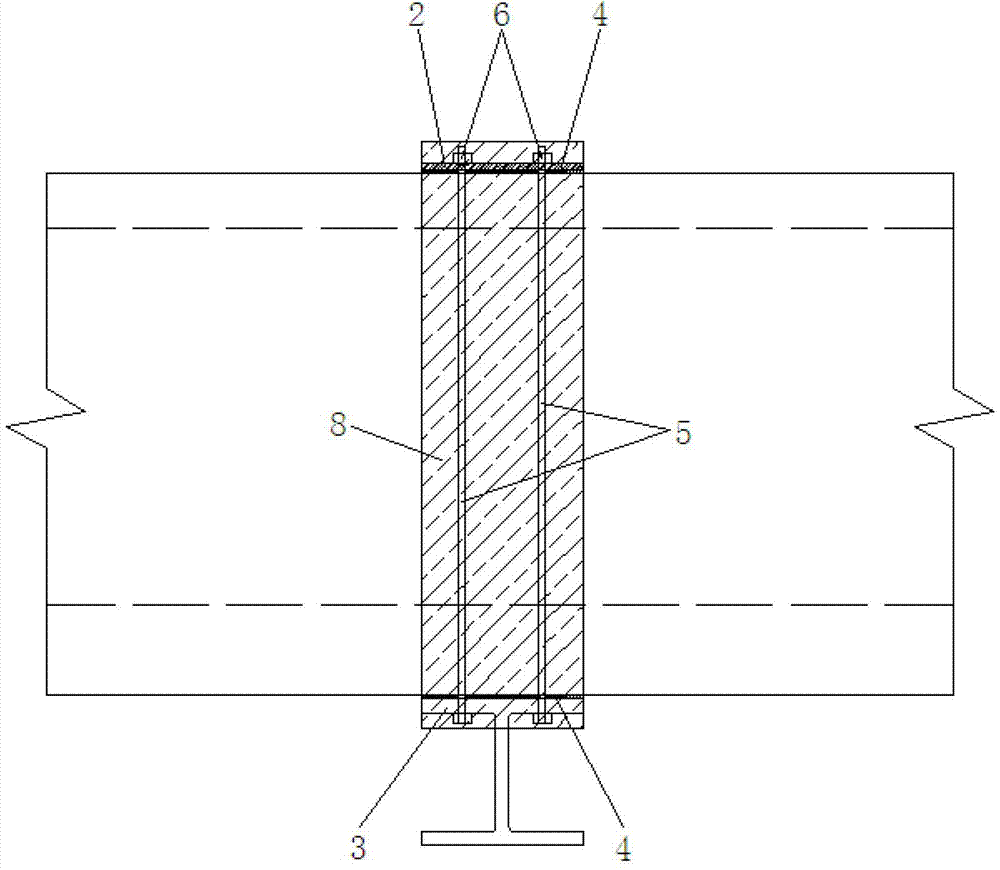

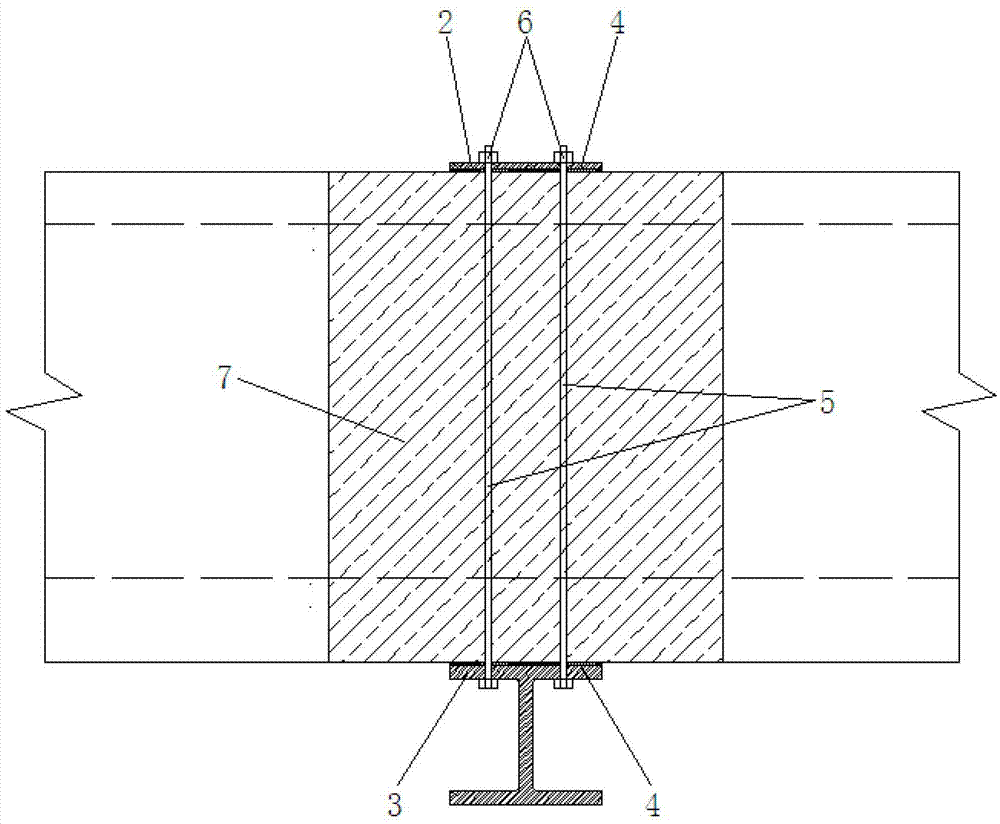

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Partial view of A, image 3 for figure 1 Sectional view at B-B, Figure 4 for figure 1 The enlarged view at C of , as shown in the figure: the concrete hollow slab bridge reinforced by transverse overall clamping in this embodiment includes a hollow slab girder, an upper reinforcement 2, a lower reinforcement 3 and connectors, and the hollow slab girder consists of The hollow plates 1 are arranged side by side. The upper reinforcement 2 and the lower reinforcement 3 are correspondingly arranged on the upper surface and the lower surface of the hollow plate girder. The upper reinforcement 2 and the lower reinforcement 3 are connected along the upper and lower Directional clamping is used to carry out horizontal overall clamping and reinforcement of the hollow slab girder, and the horizontal clamping of each hollow slab 1 through the upper reinforcement 2, the lower reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com