Method for using bipropellants efficiently

A propellant, two-component technology, applied in the directions of jet propulsion, rocket engine, machine/engine, etc., can solve problems such as mixing ratio and parallel discharge of tanks without active control system, eliminate single point failure, improve System reliability and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

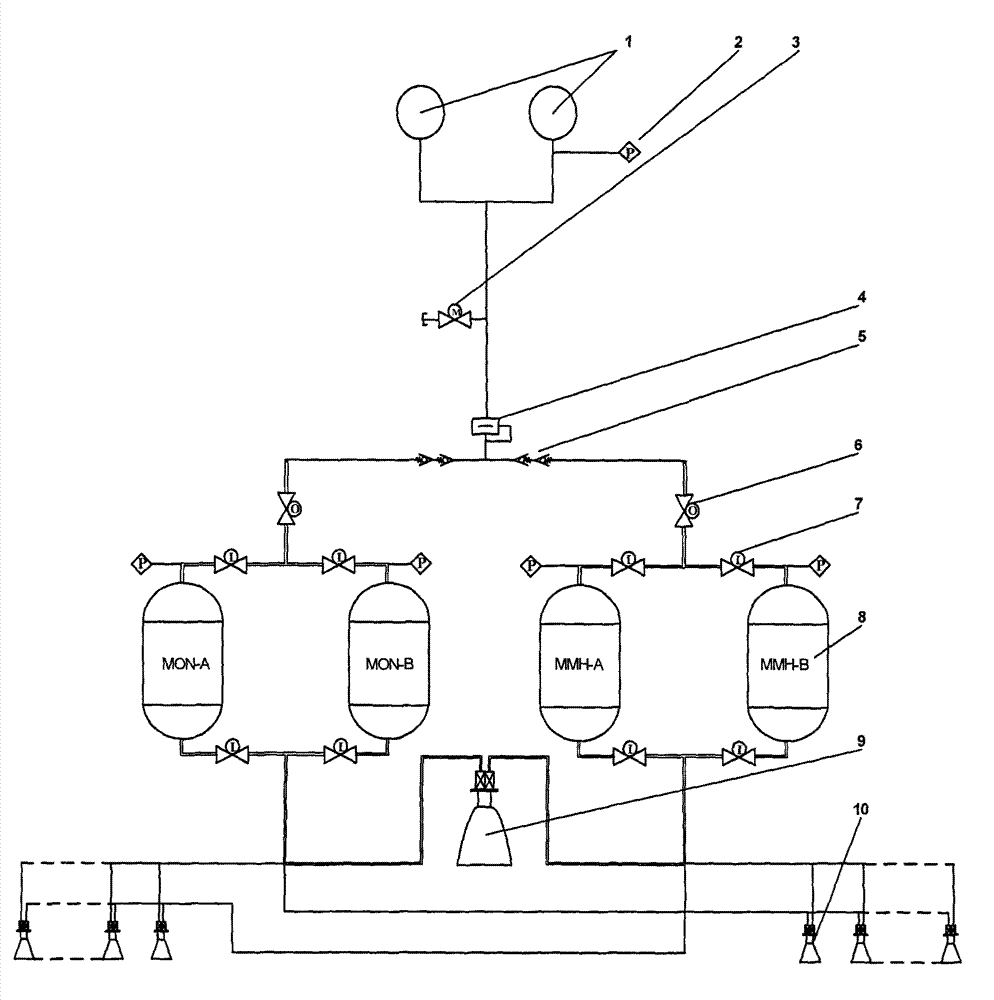

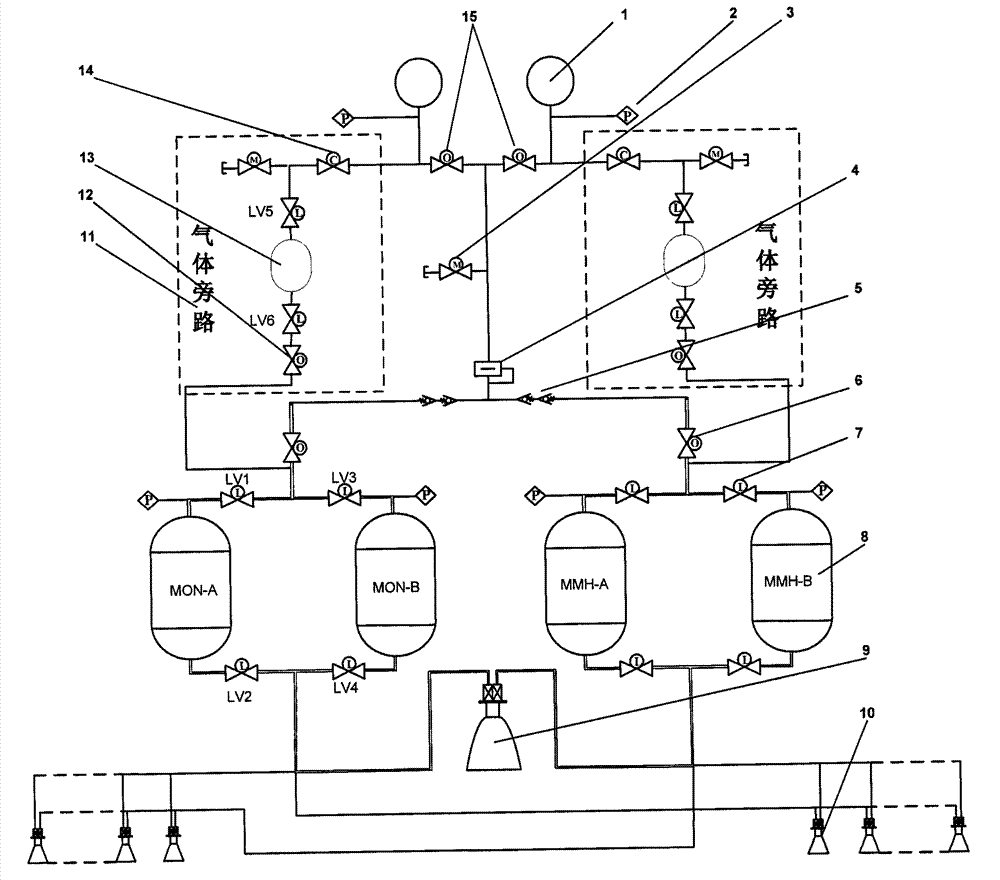

[0019] Such as figure 1 As shown, a typical dual-component propulsion system with a parallel storage tank structure for a spacecraft is basically composed of a gas cylinder 1, a pressure sensor 2, a discharge valve 3, a pressure reducer 4, a one-way valve 5, a normally open electric explosion valve 6, and a self-locking valve. Valve 7, propellant storage tank 8, orbit control engine 9 and attitude control thruster 10, wherein gas cylinder 1 is used to store high-pressure gas (usually helium); propellant storage tank 8 is used to store propellant; gas cylinder 1 and the propellant tank 8 are connected by a pressure reducer 4 and a one-way valve 5, and are equipped with necessary pressure sensors 2, discharge valve 3, normally open electric explosion valve 6 and self-locking valve 7; the pressure reducer 4 It is used to decompress the high-pressure gas in the gas cylinder 1 and inject it into the propellant tank 8 to maintain the pressure stability of the propellant tank 8; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com