Vibrating diaphragm fan, mobile phone applying same and diaphragm vibrating and ventilating method

A technology for fans and mobile phones, applied in the field of ventilation devices, can solve the problems of poor thermal conductivity, crash, heat transfer, etc., and achieve the effects of good heat dissipation, simple structure and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

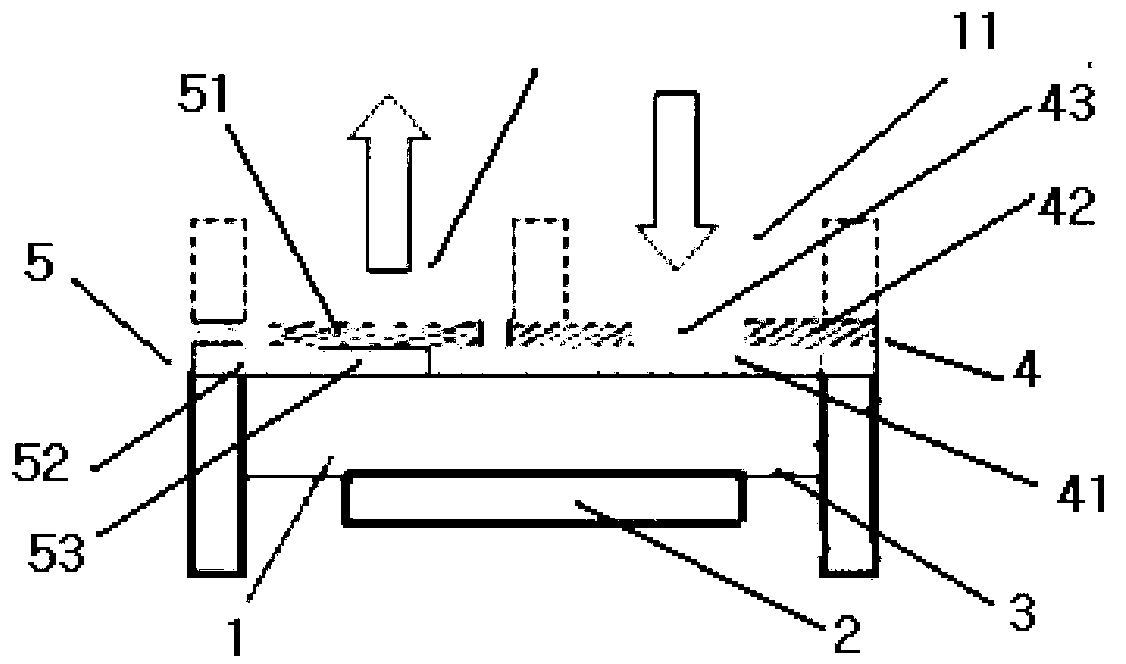

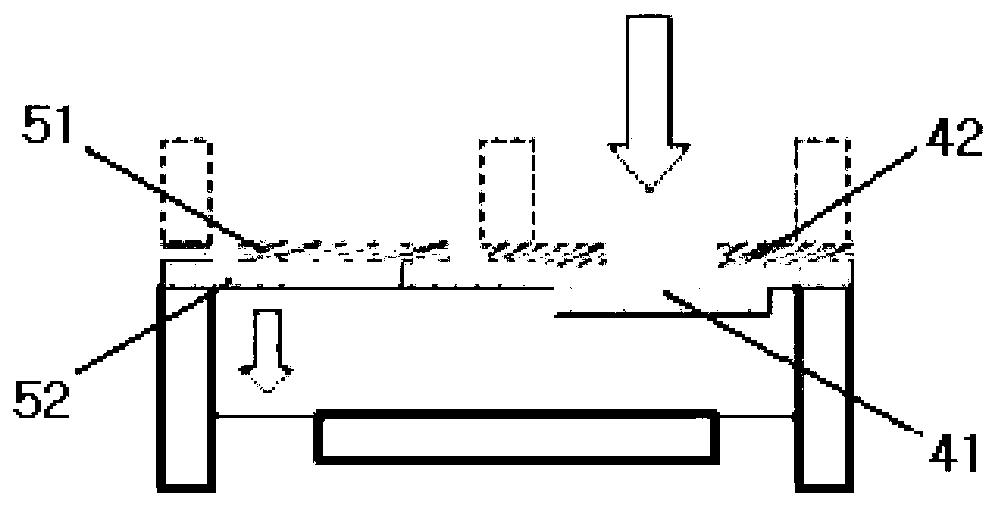

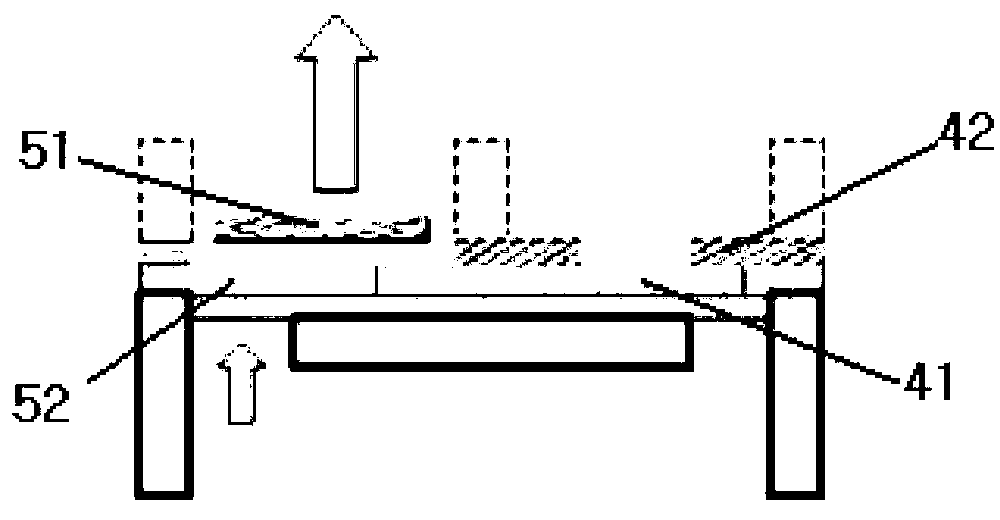

[0031] In order to make those skilled in the art better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings, as Figure 1 to Figure 4 As shown, the diaphragm fan in Embodiment 1 of the present invention includes a closed cavity 1 and an electromagnetic coil 2. An active diaphragm 3, an air inlet rectifier 4 and more than one air outlet rectifier 5 are arranged in the closed cavity. The coil 2 is connected with the control circuit and installed integrally with the active diaphragm 3 to drive the active diaphragm 3 to vibrate. The circuit diagram is as follows Figure 5 As shown, by inputting a square wave signal with a frequency of F0, through the following driving circuit, the driving circuit forms a class AB audio amplifier through two amplifiers and several resistors and capacitors, and the input square wave is converted by the integral operation of C1 and R1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com