Vertical induction heating continuous carbonization furnace

A technology of induction heating and carbonization furnace, which is applied in the field of vertical induction heating continuous carbonization furnace, which can solve the problems that production cannot continue and blocks block the working channel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

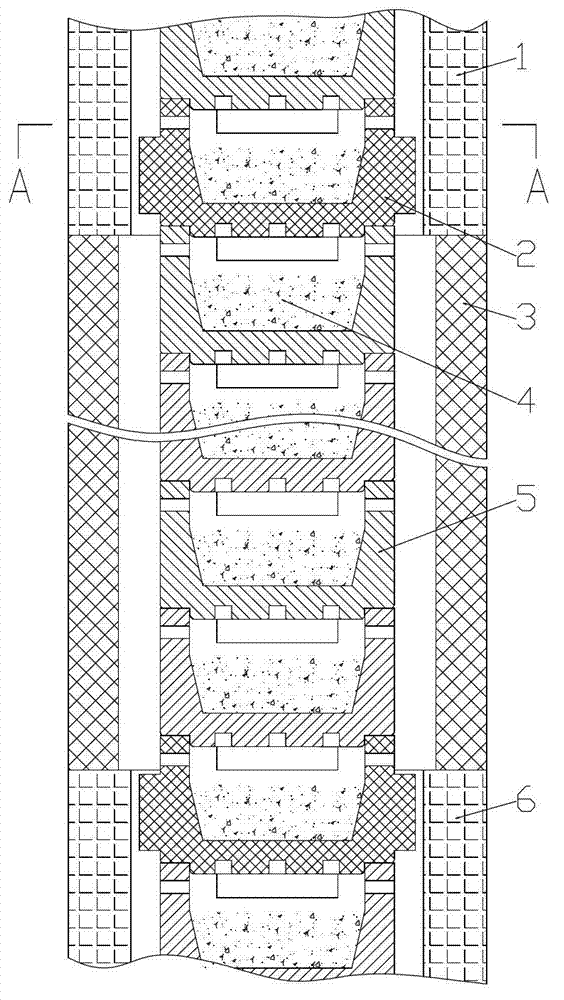

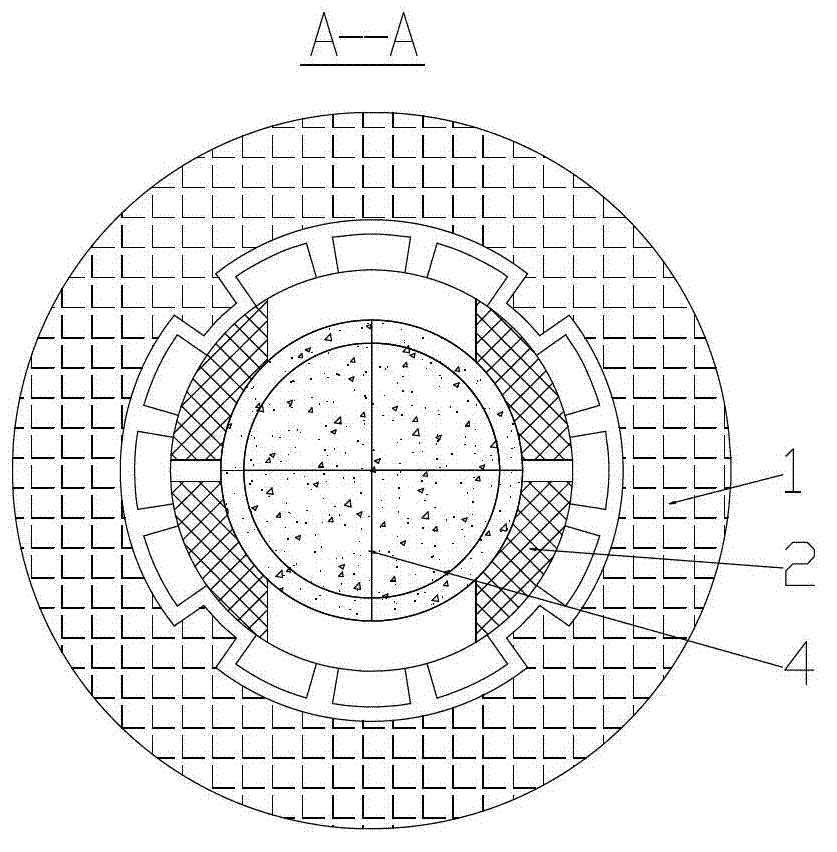

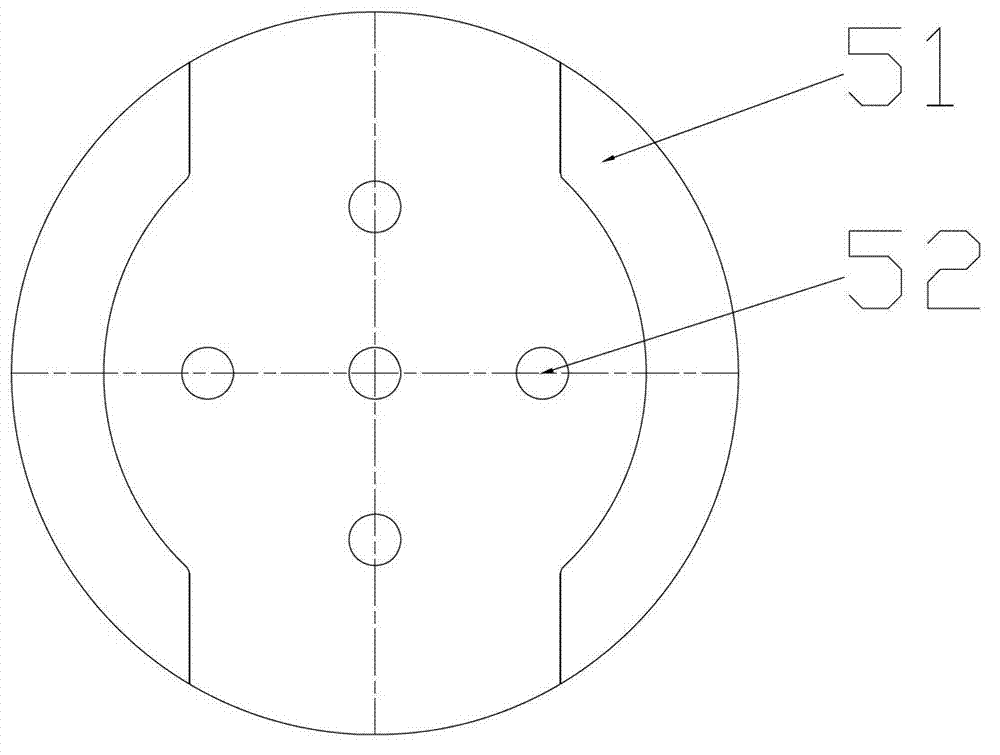

[0026] Referring to the above drawings, a vertical induction heating continuous carbonization furnace, including a furnace and a boat, is characterized in that the furnace is composed of a cylindrical heating element 3 and a cylinder that is coaxially arranged at the upper and lower positions of the heating element 3 The upper positioning sleeve 1 and the lower cylindrical positioning sleeve 6 are composed;

[0027] The upper positioning sleeve 1 and the lower positioning sleeve 6 are two positioning sleeves with the same structure, and the inner cavity arc surfaces of the upper positioning sleeve 1 and the lower positioning sleeve 6 are provided with two kinds of concentric rings with different diameters. The convex teeth on the arc surface and the concave positioning grooves, the convex teeth and the concave positioning grooves on the concentric arc surface are alternately connected in series along the circumferential direction, the convex teeth point to the center of the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com