Composite sinter plate and preparation method thereof, and sinter-plate dust catcher

A technology of plastic burning board and plastic, which is applied in the direction of separation methods, chemical instruments and methods, membrane filters, etc., can solve the problems of low tensile strength, etc., and achieve the effects of increasing strength, increasing continuous working time, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

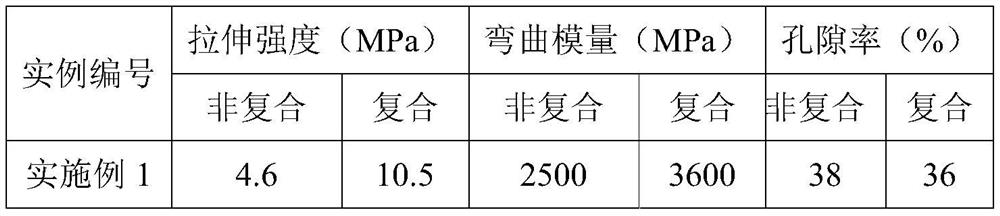

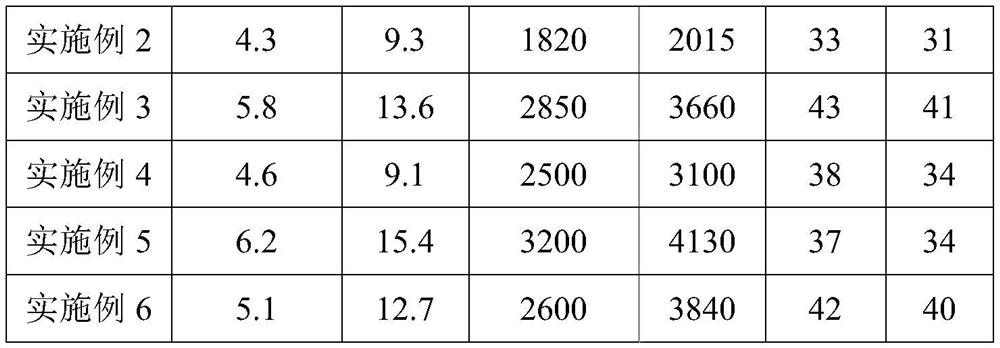

Examples

Embodiment 1

[0039] The preparation method of the composite sintered board of the present embodiment comprises the following steps:

[0040] 1) Select ultra-high molecular weight polyethylene with a molecular weight of 3.5 million and a particle size of 60-80 meshes as the resin base powder; use 5 fiber filaments (the diameter of a single fiber filament is 1 μm) to form a fiber tow for weaving processing, Made 100 mesh T300 carbon fiber mesh fabric as reinforcement material.

[0041] 2) Place the mold with a cavity height of 6mm horizontally, and spread the resin powder and the mesh fabric at intervals, respectively, from bottom to top, with one to five layers, of which the first, third and fifth layers are resin powder, and the second and fourth layers are made of resin powder. The layer is made of carbon fiber mesh fabric, and the thickness of the resin powder is spread evenly. After each layer is spread, it is vibrated to make the material dense. After the mold is closed, it is placed v...

Embodiment 2

[0045] The preparation method of the composite sintered board of the present embodiment comprises the following steps:

[0046] 1) Select polytetrafluoroethylene resin dry powder with a molecular weight of 10 million and a particle size of 80-120 mesh as the resin base powder; select a stainless steel wire mesh with a diameter of 5 μm and a mesh of 150-200 mesh as the reinforcing material.

[0047] 2) Place the mold with a cavity height of 10mm horizontally, spread polytetrafluoroethylene powder and stainless steel wire mesh at intervals, the first, third, fifth and seventh layers are polytetrafluoroethylene powder, the second and fourth layers And six layers are stainless steel fiber mesh. Spread the resin powder thickness evenly, and vibrate after each layer of paving to make the material compact. After closing the mold, place it vertically according to the actual use direction, and then put it into the sintering furnace after vibrating.

[0048] 3) Carry out four-stage gr...

Embodiment 3

[0051] The preparation method of the composite sintered board of the present embodiment comprises the following steps:

[0052] 1) Select P2 type polyphenylene sulfide with a particle size of 100-150 mesh as the resin base powder; weave the fiber tow formed by 10 fiber filaments (the diameter of a single fiber filament is 17 μm), and make 150 -200 mesh basalt fiber mesh fabric as reinforcement.

[0053] 2) Place the mold with a cavity height of 4 mm horizontally, spread polyphenylene sulfide powder and basalt fiber fabric at intervals, the first and third layers are polyphenylene sulfide powder, and the middle layer is basalt fiber fabric. Spread the resin powder thickness evenly, and vibrate after each layer of paving to make the material compact. After closing the mold, place it vertically according to the actual use direction, and then put it into the sintering furnace after vibrating.

[0054] 3) Carry out three-stage gradient sintering in the sintering furnace. The fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com