Particulate matter pm10 particle size cutting device

A cutting device, a technology for particulate matter, which is used in measurement devices, sampling devices, particle and sedimentation analysis, etc., can solve problems such as it is difficult to meet the diversified actual detection needs in the field of environmental monitoring, and achieve compact structure, ensure normal operation, and cut Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

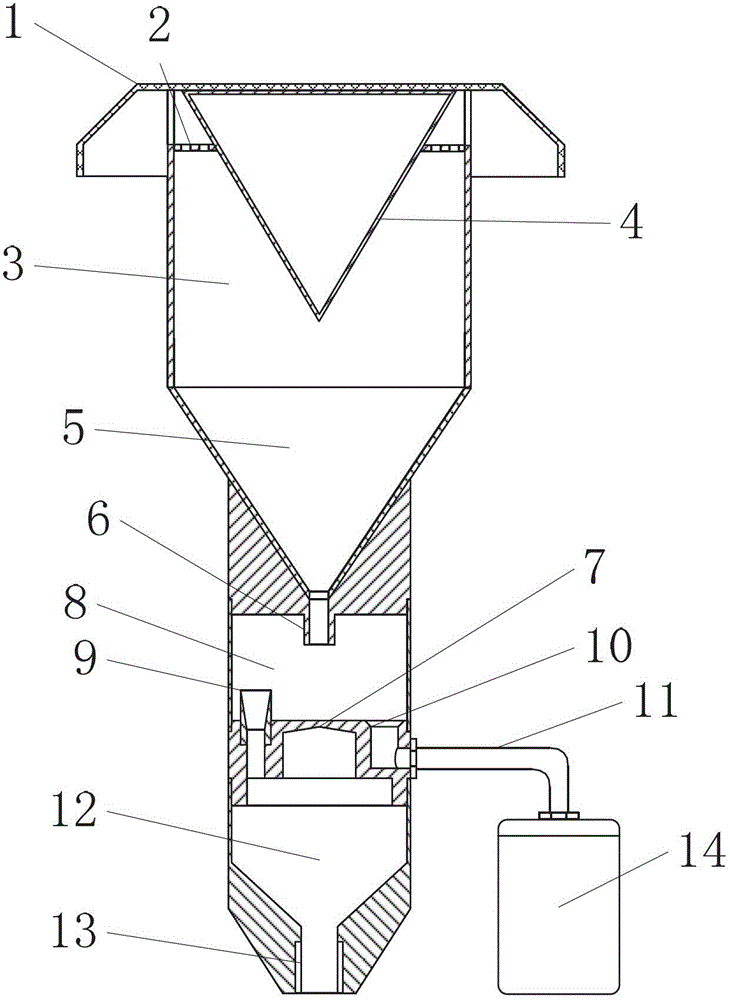

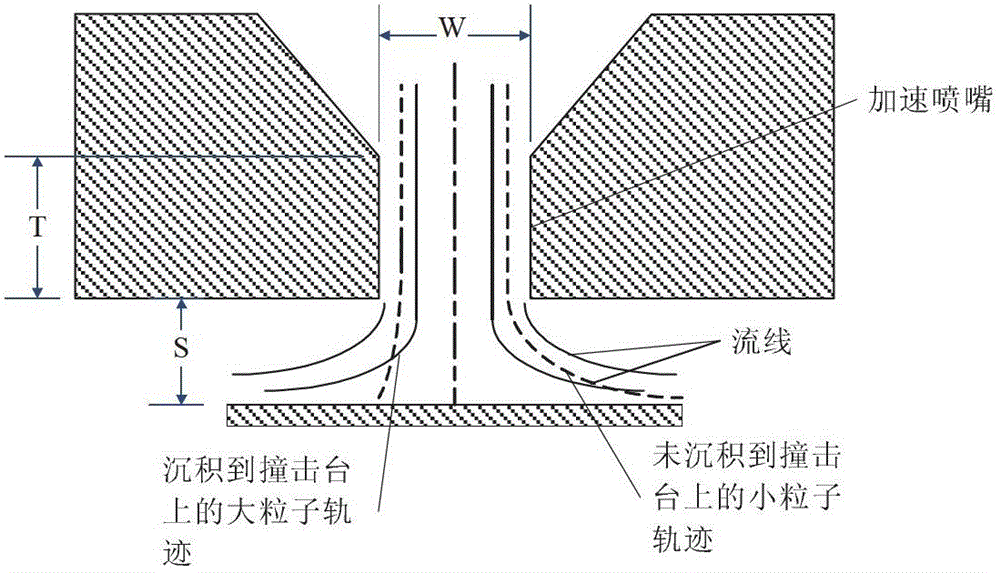

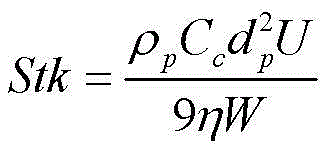

[0030] like figure 1 As shown, a particulate matter PM 10 The particle size cutting device includes a rainproof cover 1, the inside of the rainproof cover 1 is connected with a gas rectifier 4, the lower part of the rainproof cover 1 is connected with a sample gas rectification chamber 3, and the sample gas rectification chamber 3 Set on the outside of the gas rectifier 4, an annular air inlet is formed under the rainproof cover 1. The lower part of the sample gas rectification chamber 3 is connected to the sample gas acceleration chamber 5, and the lower part of the sample gas acceleration chamber 5 is An acceleration nozzle 6 is fixedly connected, and the lower part of the acceleration nozzle 6 is screwed with an inertial separation chamber 8. After the sample gas passes through the acceleration chamber, the airflow reaches a certain flow rate and enters the inertial separation chamber 8. The lower part of the inertial separation chamber 8 is fixed with an inertial impactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com