Five-axis movement positioning system

A positioning system and five-axis moving technology, applied in measurement devices, material analysis through optical means, instruments, etc., can solve the problems of strong subjectivity, high missed detection rate, low efficiency, etc., and achieve strong subjectivity and missed detection. High rate and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

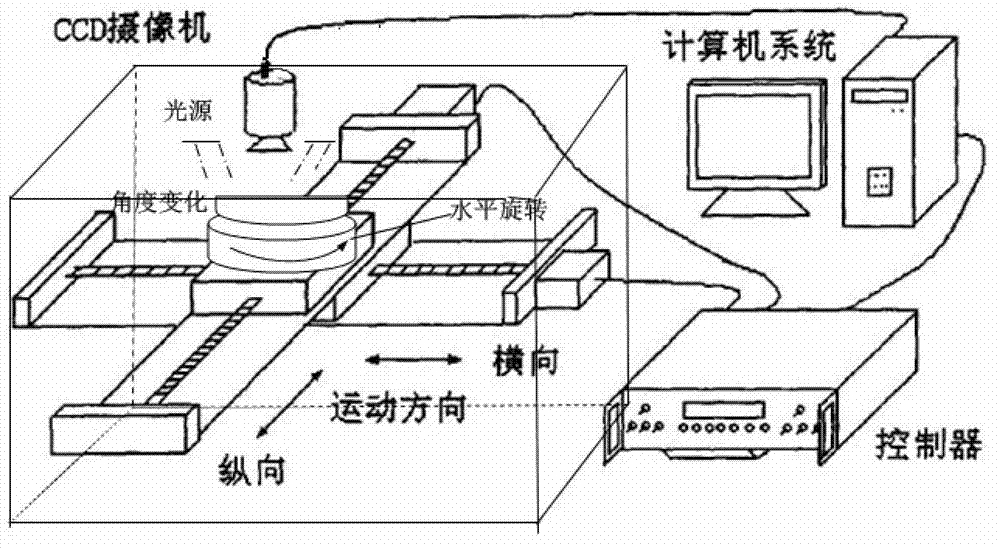

[0039] Please refer to the attached figure 1 , which is a structural schematic diagram of a five-axis motion positioning system provided by an embodiment of the present invention, including:

[0040] Chassis shell;

[0041] An optical lighting device arranged on the inner top of the chassis shell to provide a lighting environment for the PCB board to be detected;

[0042] A five-axis moving device for fixing the PCB board to be detected and realizing five-axis movement is arranged under the optical lighting device;

[0043] A controller connected to the five-axis moving device and used to control the five-axis moving device to perform corresponding five-axis motion according to signals from an external computer;

[0044] It is arranged below the five-axis moving device and is used for the conveyor belt to detect the PCB board conveyor.

[0045] The invention provides a five-axis motion positioning system, which includes: a case shell, an optical lighting device, a five-axis...

Embodiment 2

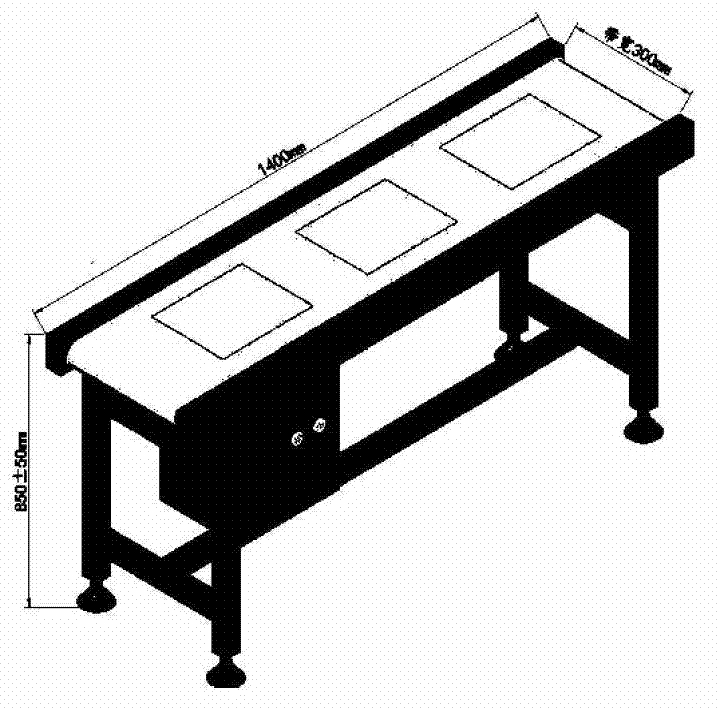

[0047] On the basis of the first embodiment above, this embodiment includes: a chassis shell; an optical lighting device arranged on the inside top of the chassis shell for providing a lighting environment for the PCB board to be detected; arranged below the optical lighting device A five-axis moving device used to fix the PCB board to be detected and realize five-axis movement; it is connected to the five-axis moving device and used to control the five-axis moving device to perform corresponding five-axis movement according to signals from an external computer The controller; arranged below the five-axis moving device, outside the conveyor belt used to detect the PCB board conveyor, the present invention also provides a stage, the object stage is arranged on the five-axis moving device, It is used to place the PCB board to be tested and has multiple threaded holes, such as image 3 shown.

[0048] It should be noted that the stage is used to place the PCB board. Since the si...

Embodiment 3

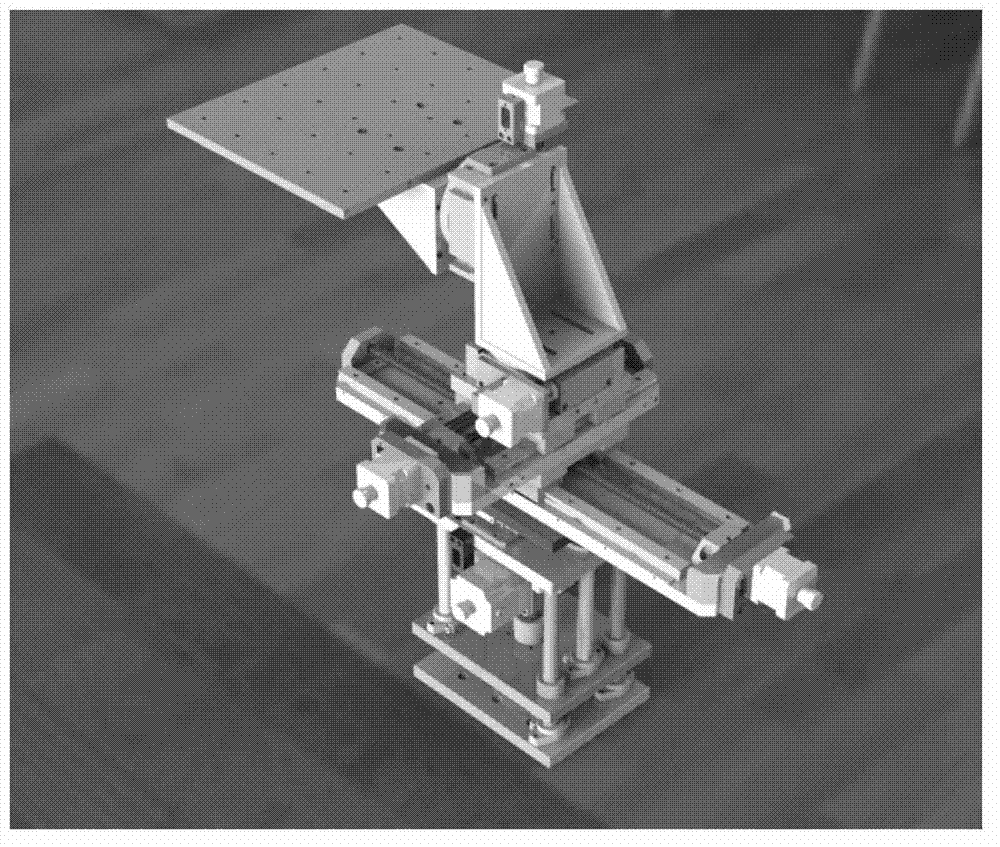

[0061] see Figure 5 , on the basis of the above-mentioned embodiments provided by the present invention, preferably, a magnetic clamping device for clamping the PCB board to be tested is further included.

[0062] The inventor considers that after the PCB board is transported to the loading platform through the installation device, the motion positioning platform will move to the detection position. In addition, during the detection process, the loading platform will also rotate and swing, so the PCB board installation device is installed on the loading table. The object table needs to remain still, that is, it needs to be clamped.

[0063] Clamping methods mainly include manual, pneumatic, hydraulic, electric, electromagnetic, magnetic, vacuum suction and so on. With the rapid development of the machinery manufacturing industry, the promotion of automation and semi-automation equipment, and the need to reduce the labor intensity of operators in mass production, most of them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com