Portable magnetic metal fatigue detection method

A magnetic metal, fatigue detection technology, applied in the direction of material breakdown voltage, etc., can solve the problems of inability to weld and other defects diagnosis, provide a clear basis for repair, operator health threat, expensive and other problems, to facilitate monitoring and follow-up processing , The measurement process is simple and convenient, easy to mark and record the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

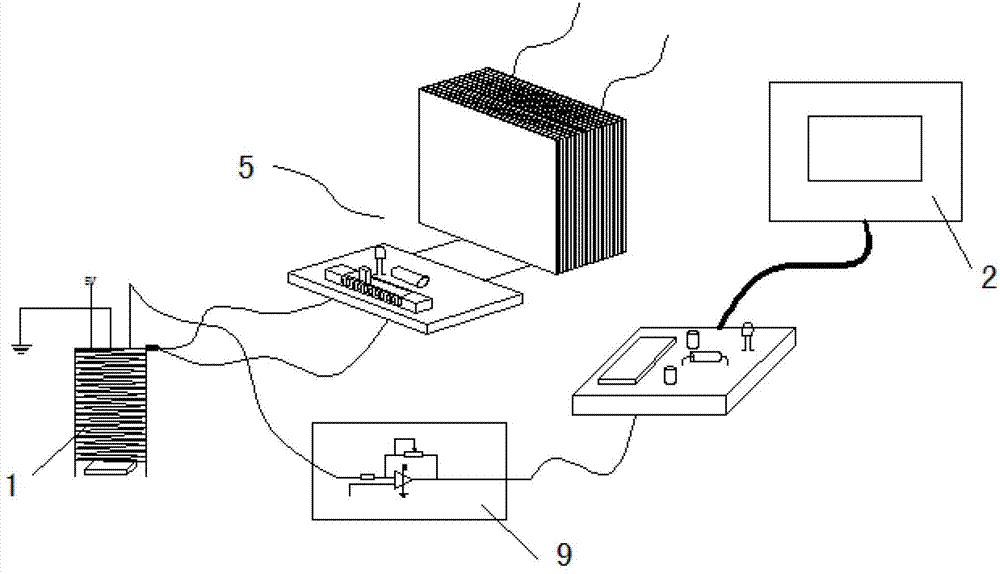

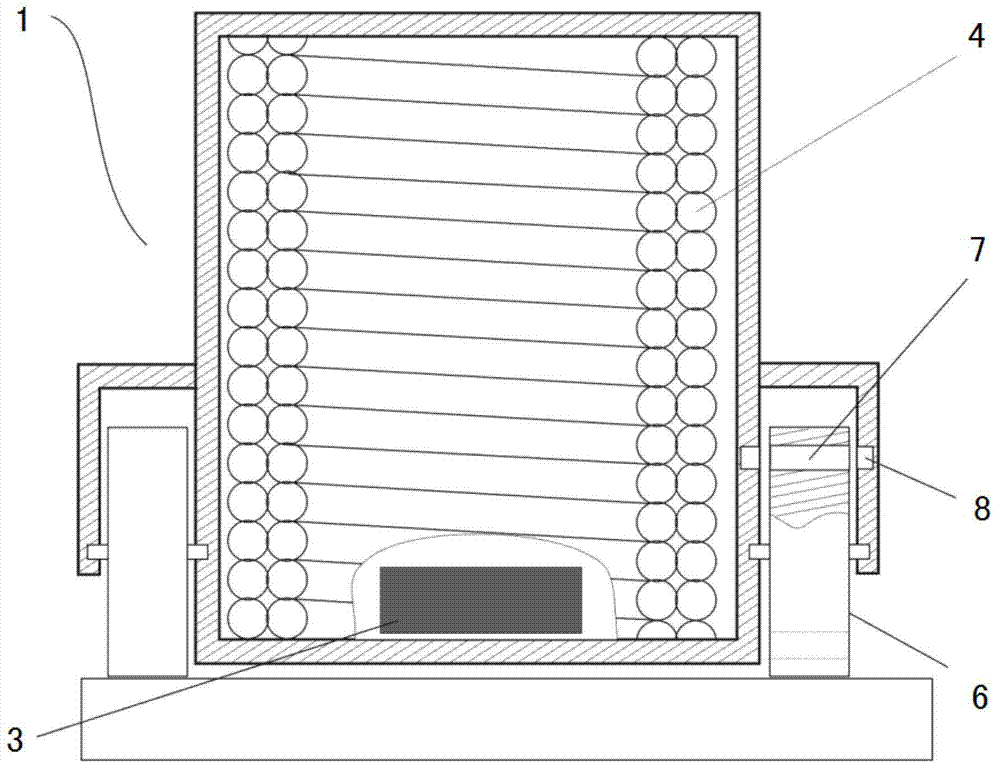

[0035] like figure 1 As shown, it is a structural schematic diagram of one of the portable magnetic metal fatigue detectors suitable for the portable magnetic metal fatigue detection method of the present invention. The portable magnetic metal fatigue detector comprises a probe 1, a data processing device connected to the probe 1 and a display 2 connected to the data processing device and used for displaying waveforms. The probe 1 includes a Hall sensor 3 for detecting the rate of change of a magnetic field and a stable The voltage and direct current power supply 5 is connected and used to generate the electromagnet coil 4 of the magnetic field. The Hall sensor 3 is installed at one end of the electromagnet coil 4 and is located on the top of the probe 1 .

[0036] In this portable magnetic metal fatigue detector, an electromag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com